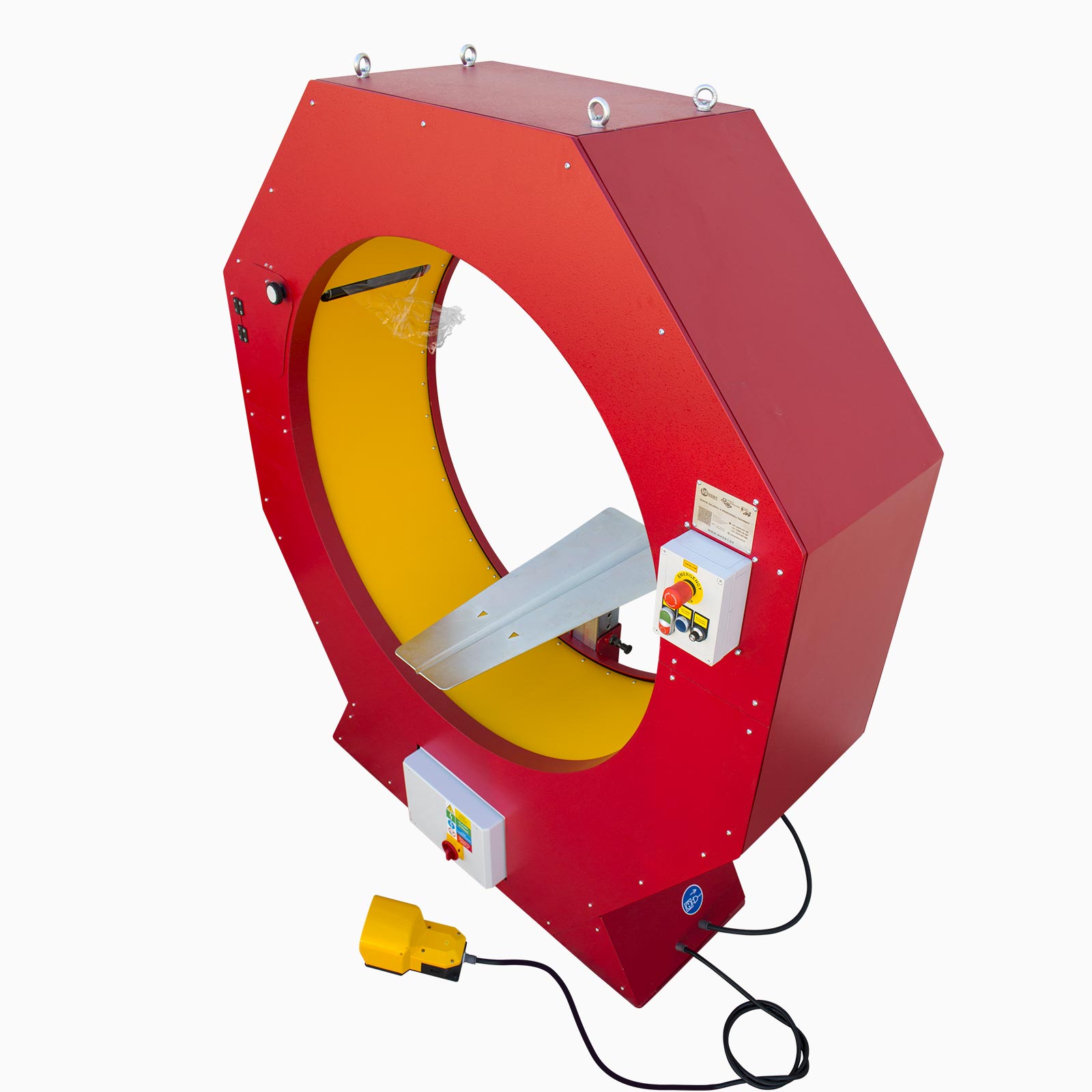

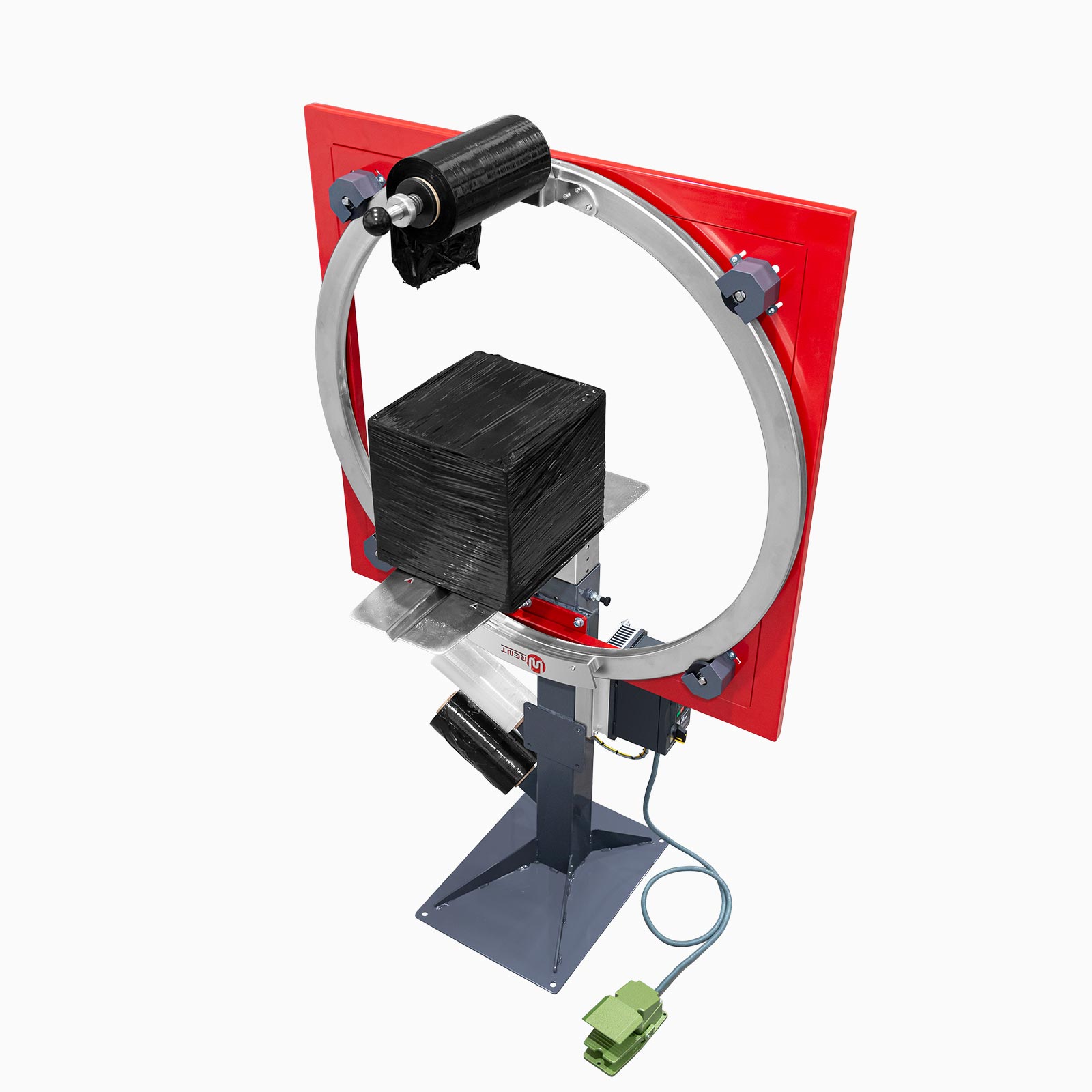

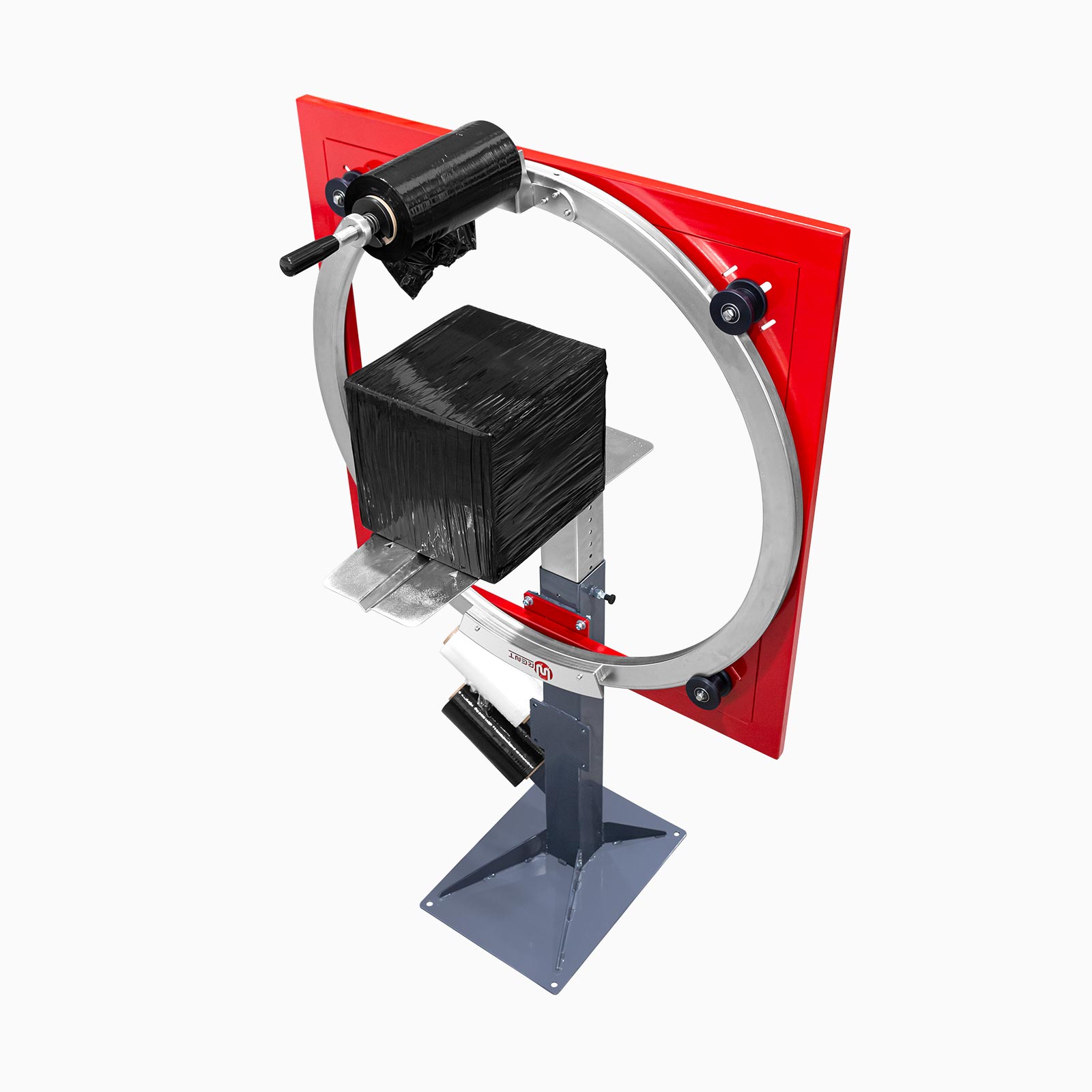

Baliace technológie

a obalové materiály pre každý spôsob balenia

Starostlivosť a údržba baliacich strojov

Spoľahlivý servis

baliacich technológií 24/7

Výroba reklamnej lepiacej pásky

Lepiaca páska s potlačou

Najdostupnejšia reklama a neustále v pohybe

Novinky

Z našej ponuky