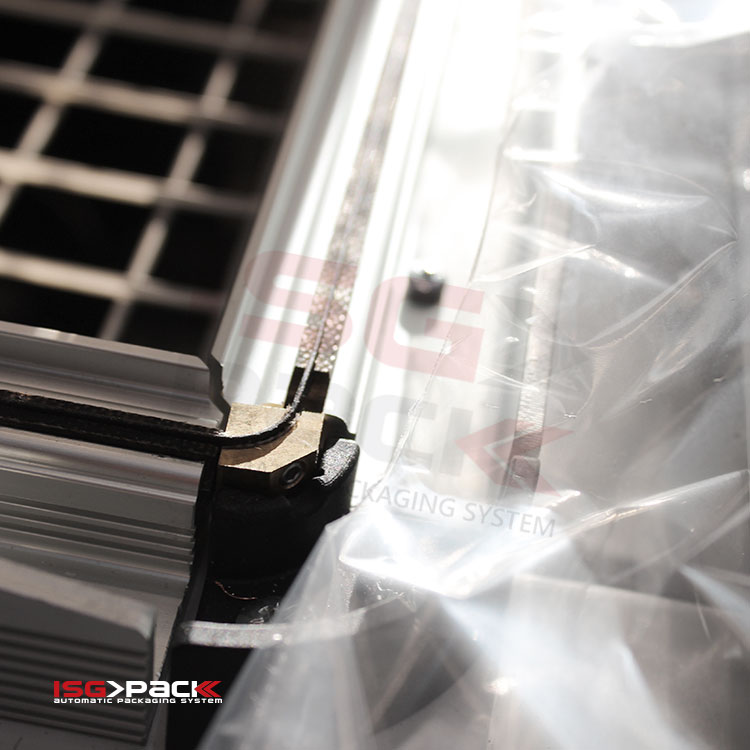

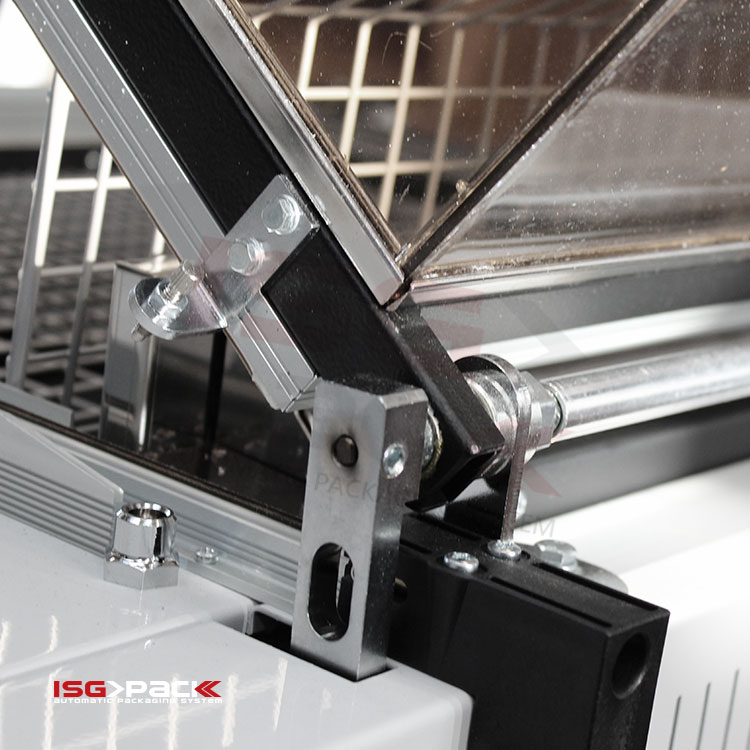

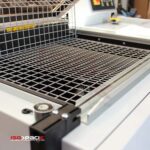

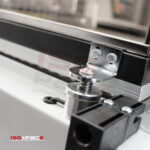

The new Easy Sealer 55 series chamber shrink machines have a solid steel construction, the latest generation electronics with a user-friendly control panel. They have a larger work table and several technical details that improve their performance. OPERATION: The operator inserts the product into the shrink wrap, guides it into the sealing compartment and closes the chamber. Sealing and shrinking are performed simultaneously.

Features and optional equipment of the packaging machine

Options

- Double coil support

- Waste recovery facility

- Stainless Steel Workbench

Features

- Sealing and shrinking in one operation

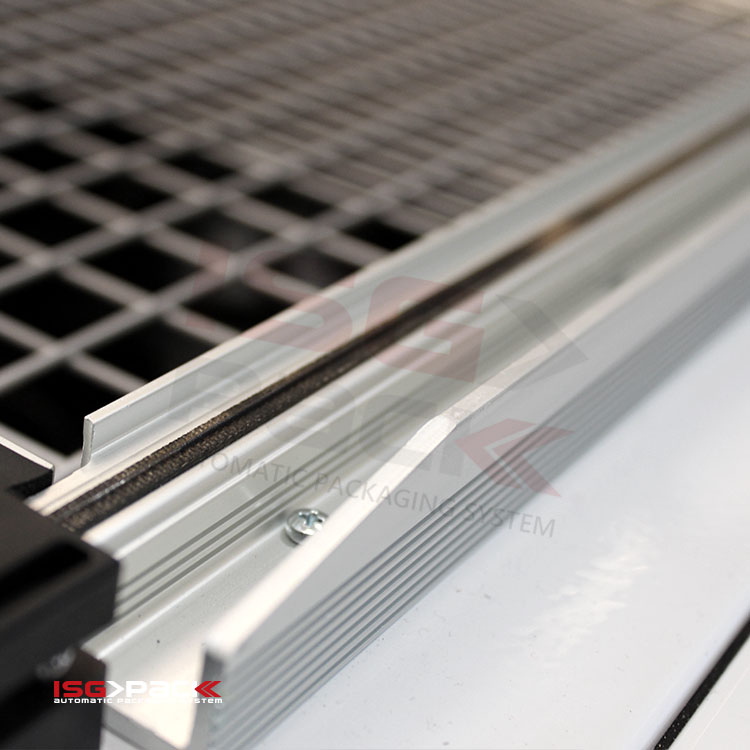

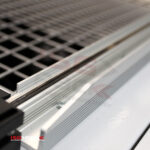

- Teflon-coated sealing blade

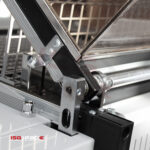

- Height adjustment of the inner packing plate

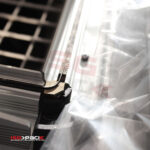

- A movable product holding plate, released from the film roll support, which allows for a better adaptation of the film to the pack shot

- Electromagnet for holding the cover

- Automatic cover release

- Air cooling of the machine frame

- Flextron control system equipped with:

- Alphanumeric LCD control panel equipped with 16-bit

microprocessor card, which allows easy and precise control of all machine operations, such as: machine status; number of packages produced using the electronic package counter; seal temperature setting

shrink time setting; shrink chamber temperature setting; shrink delay setting; cover opening delay setting; automatic cover closing and reopening, the possibility to schedule up to 10 different working cycles, resulting in increased productivity and simplified troubleshooting in use - Modular power supply part separated from the control panel, which is characterized by: solid-state relays with longer lifetime, which facilitate maintenance in case of failure, the possibility of replacing only the damaged module without loss of data stored in memory.

- Reduced energy consumption

- Compliance with CE regulations

Benefits

- Easy to use: the Easy Sealer 55 is designed with ease of use in mind. The user interface is intuitive, making it quick and easy to set up and use the machine, even for less experienced operators.

- Fast and efficient packaging: the machine is designed to work quickly and efficiently, increasing productivity and reducing the time needed to package products.

- Flexibility: the Easy Sealer 55 offers the possibility to customize settings such as temperature and speed, thus adapting to different types of packaging materials and product sizes.

- Energy saving: this machine is often equipped with energy-efficient technologies, which can lead to lower operating costs and reduced environmental impact.

- Compact design: the Easy Sealer 55’s compact size allows it to be positioned in a variety of workspaces, making it ideal for smaller operations or confined spaces.

- High quality sealing: The machine provides high quality sealing to ensure that the products are well protected during transportation and storage.

- Low maintenance: the Easy Sealer 55 requires minimal maintenance, which reduces service costs and increases operational efficiency.

- Waste reduction: efficient use of packaging material means less waste, which contributes to lower costs and greener practices.

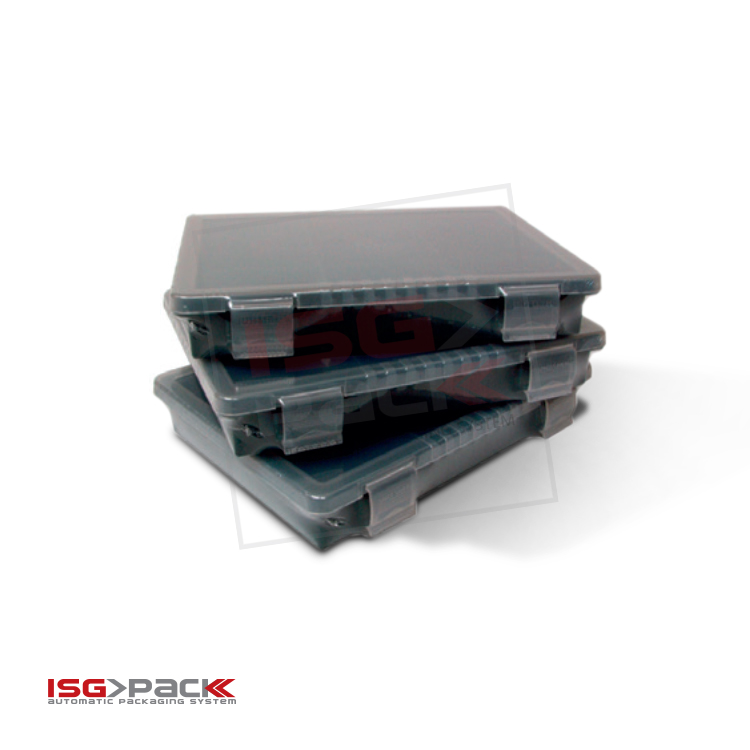

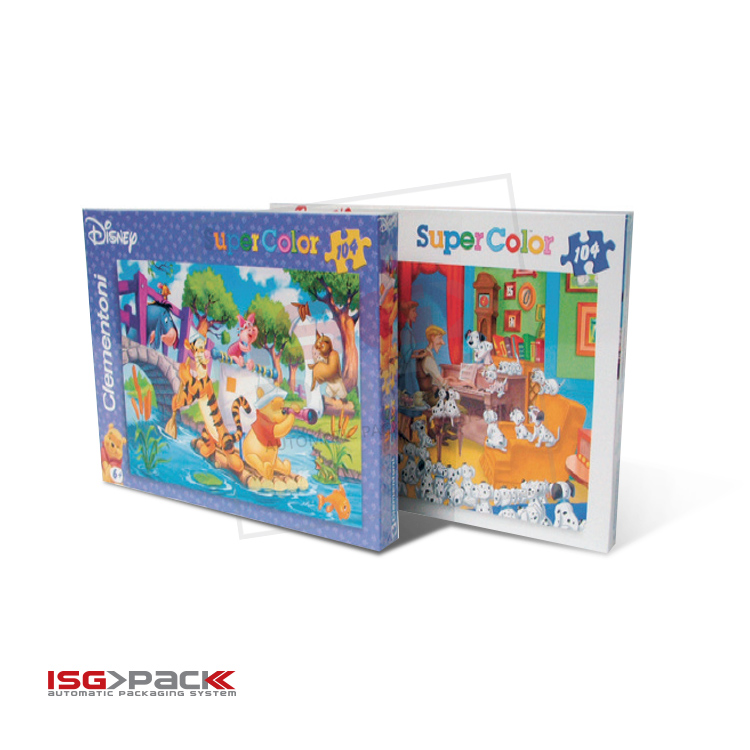

- Wide range of applications: The machine is suitable for different types of products and packaging, making it a versatile tool for a variety of industrial and commercial applications.

- Safety features: Modern packaging machines, including the Easy Sealer 55, usually include safety features to protect operators from potential accidents.