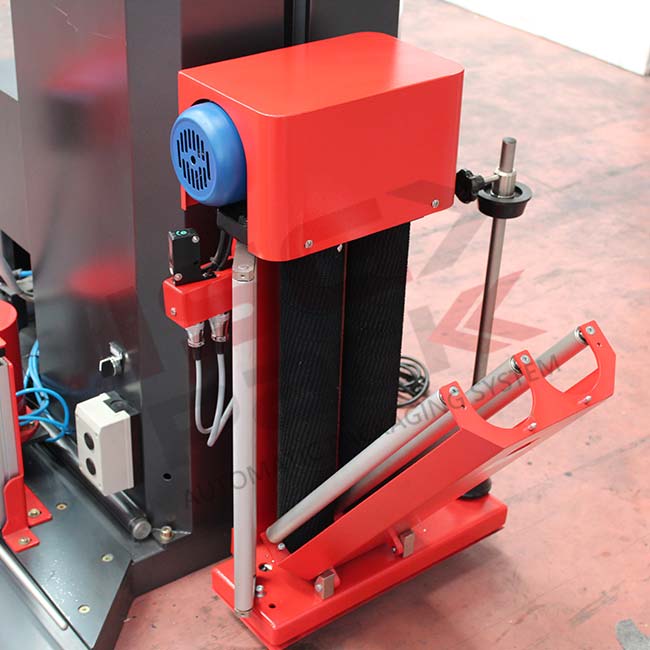

The automatic wrapping machine for pallet wrapping is equipped with a cutting and end sealing unit for perfect adhesion of the film to the pallet

The Ultra Wrap 2000 BF pallet wrapping machine is an automatic machine and is the ideal solution for wrapping pallets fully automatically. The machine is equipped with a gripper and a fixed tail cutting unit that ensure the film is hooked, cut and sealed while maintaining perfect adhesion to the pallet. The machine is powered by electricity and requires an energy output of 1,25 kW. It has a turntable speed of 12 rpm (revolutions per minute) and a carriage rise and fall speed of 1.4 / 4 m-min.

General features of the wrapping machine

The Ultra Wrap 2000 BF pallet wrapping machine has a turntable diameter of 1650 mm (standard) and can handle products with dimensions d 1000 x w 1200 x h 2600 mm with a maximum turntable weight of 2000 kg. To regulate the number of rotations on the bottom and top of the pallet, the table can also be controlled to run slowly by means of an inverter. There is also a PLC on the winder and a 7.2 colour touch screen display which allows you to set other parameters such as the carriage rise and fall speed, photocell reading delay, cycle counter etc.

- Machine construction made of painted steel sheet

- Turntable diameter ø 1650 mm

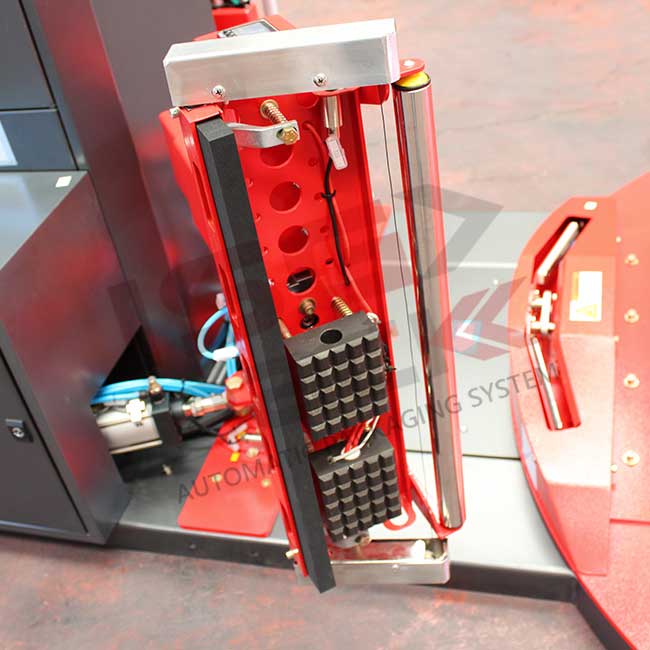

- Sealing system for cutting foil

- Electric top press unit (Ultra Wrap 2000 BFC)

- Foil welding system controlled by temperature controller

- Packing cycle activated by remote control

- Machine controlled by PLC and 7,2″ colour touch screen

- Safety stop device on the bottom of the trolley in accordance with CE regulations

- Locking/unlocking brake device for easy hanging of the film on the pallet

- Acoustic warning with light signal during the start cycle

- Motorised preload set at 200% with exchange option

- pre-stretch ratio 100%, 150%, 250%

- CE compliant reset button

- Inverter for slow start and indexed turntable stop

- Cycle counter

- Manual working mode of the machine

Parameters adjustable via control panel

- Number of laps on the bottom of the pallet (starting cycle)

- Number of rounds at the top of the pallet

- Adjustable plate rotation speed from 0 to 10 rpm

- Trolley height adjustment for opening the foil clamp

- Adjustable trolley rising speed

- Adjustable trolley descent speed

- Adjustable number of ascending and descending cycles

- Adjusting the position and slowing down the table at the end of the cycle

- Adjustable photocell delay

- Welding and foil cutting parameters setting

- Blowing time adjustment eliminates tail

- Film feed speed setting

- Digital adjustment of the turntable speed

- I/O for self-diagnosis

Cycles activated by the control panel

- Ascending and descending cycle

- Rise and fall cycle for the leaf feeder

- Upper leaf cycle (ascending/descending)

- N° 10 programmable cycles via touch screen by product/pallet per pack

Product Features

- Product dimensions: d 1000 x w 1200 mm.

- Maximum product height: 2500 mm.

- Maximum product weight: 2000 kg.

Features film roll

-

Outer diameter of the foil roll: 280 mm.

-

Inner diameter of the foil roll: 76 mm.

-

Height of the film roll: 500 mm.

-

Maximum disc weight: 16 kg.