Packing of pallet shipments on an automatic conveyor

The PKG SMARTWRAP-A wrapping wrapping machine is the ideal solution for automatic wrapping of pallets in stretch film for a packaging line, for a production line or for a shipping warehouse. The wrapping machine can be installed in an existing conveyor line, from which the consignments will enter the machine on an integrated motorised roller conveyor and, after wrapping in film, continue on the conveyor at the exit of the wrapping machine for further processes prior to dispatch. The PKG SMARTWRAP-A has an advanced module for automatic stretch film cutting, automatic stretch film clamping as well as automatic film termination and sealing.

Key features

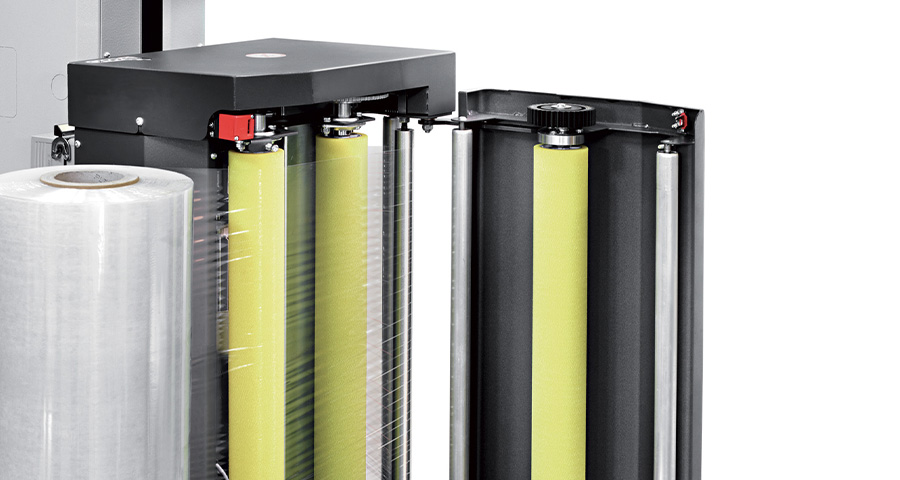

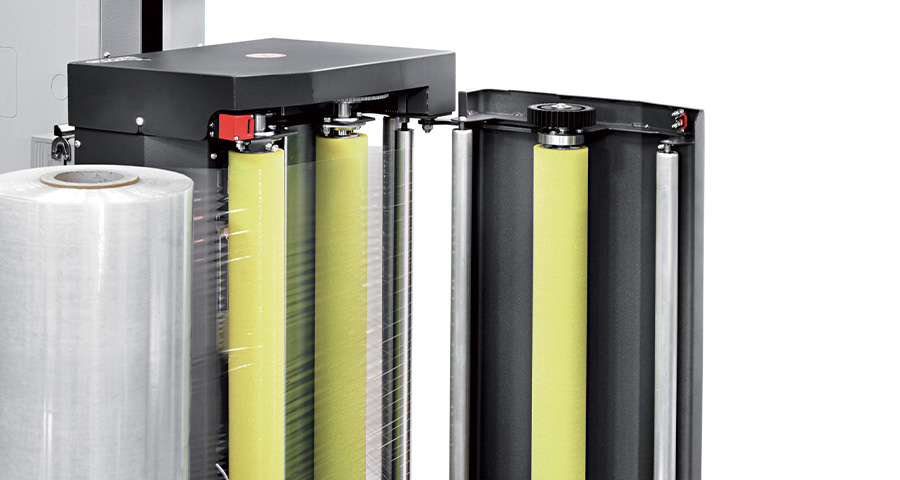

- Foil trolley with EB electromagnetic brake or motorised pre-tensioning (MPS/MPS2),

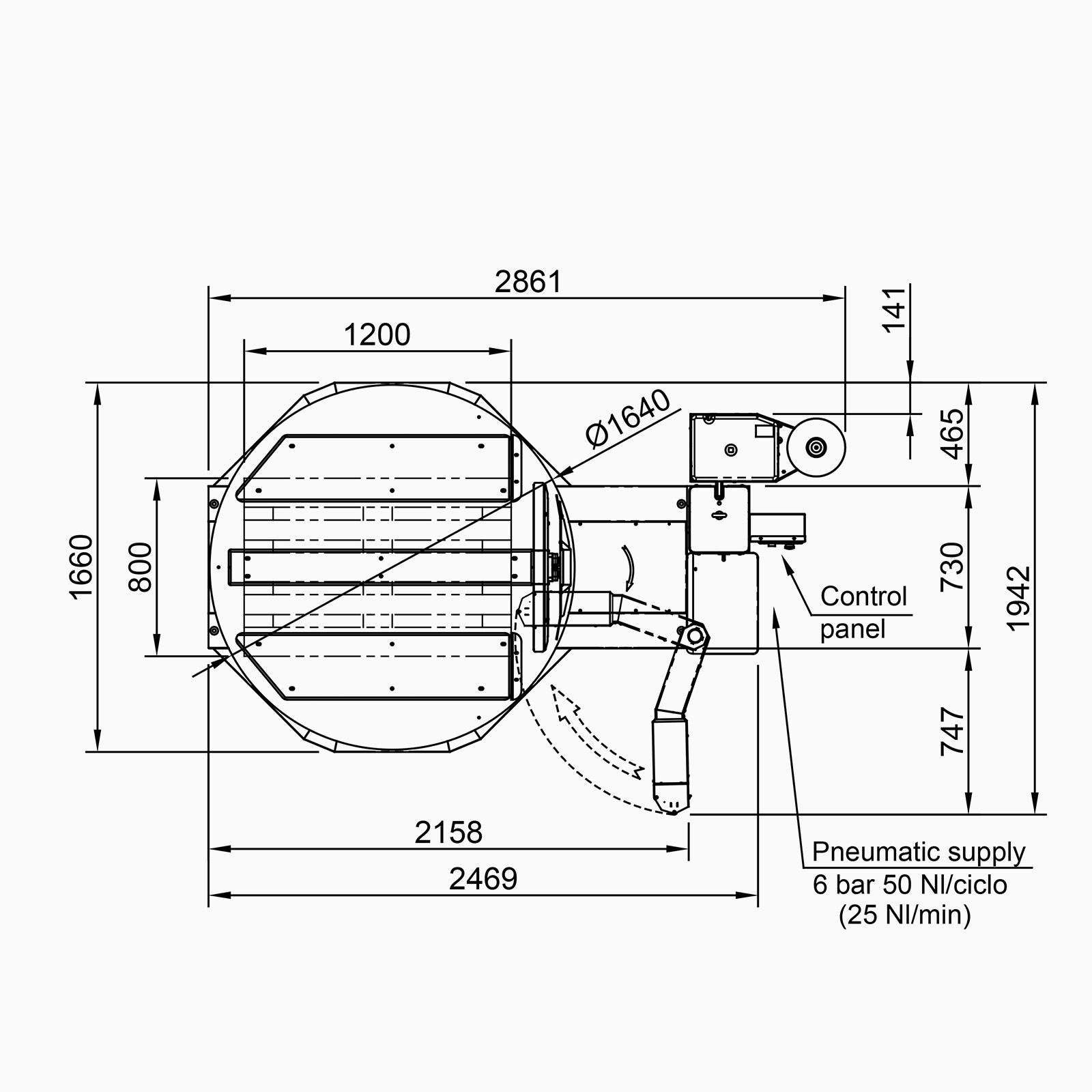

- Turntable diameter 1800 mm,

- Max. shipment weight 1500 Kg,

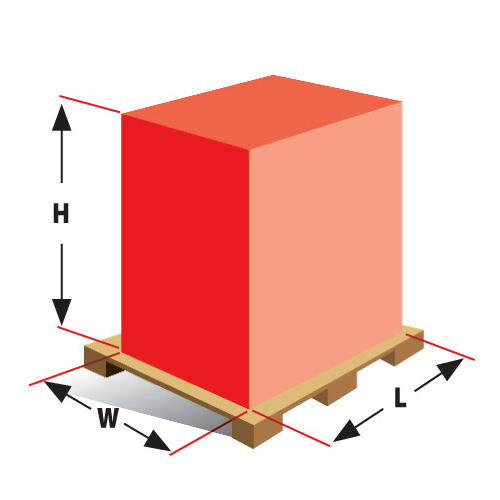

- Max. dimensions of the consignment (floor plan) 1000 x 1200 mm,

- Height of the shipment detected by the photocell,

- Max. shipment height 2300 mm,

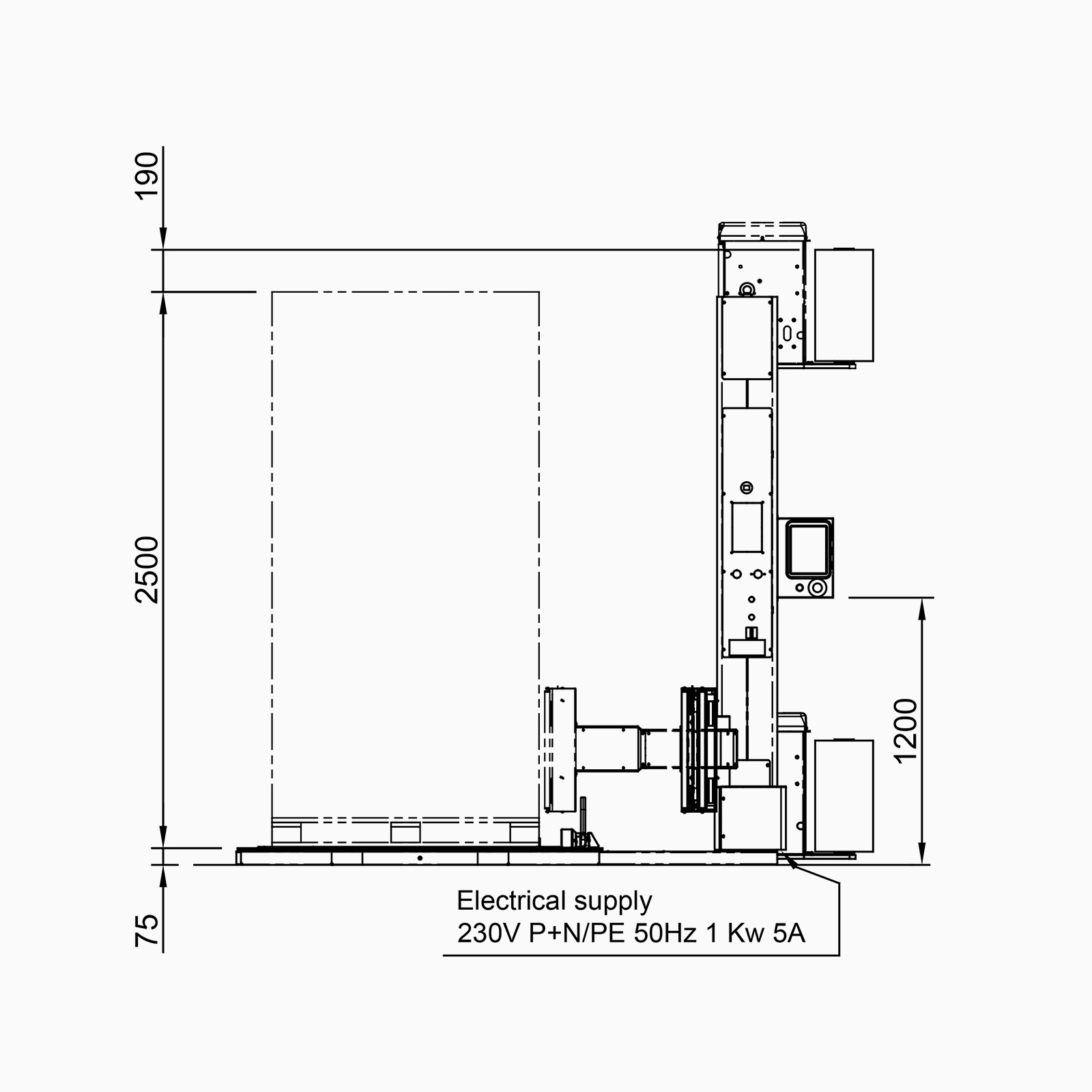

- Working height of roller conveyors from 190 to 500 mm,

- Automatic stretch film clamping and closing system,

- Automatic system for cutting off the foil and attaching the end of the foil,

- Automatic unit for sealing the cut part of the stretch film (optional accessory).

Configuration options

Electromagnetic brake EB – EB foil trolley with electromagnetic brake

Motorised pre-stretching MPS – MPS film trolley with motorised film pre-stretching, switchable film pre-stretching levels

MPS2 Powerful Motorised Prestretching – MPS2 film trolley with powerful motorised film prestretching, with adjustable film prestretching level

Automatic strapping – additional unit for the film trolley for automatic strapping of the consignment

Stabilization unit – unit with a clamping arm for stabilizing the pallet shipment during packing.