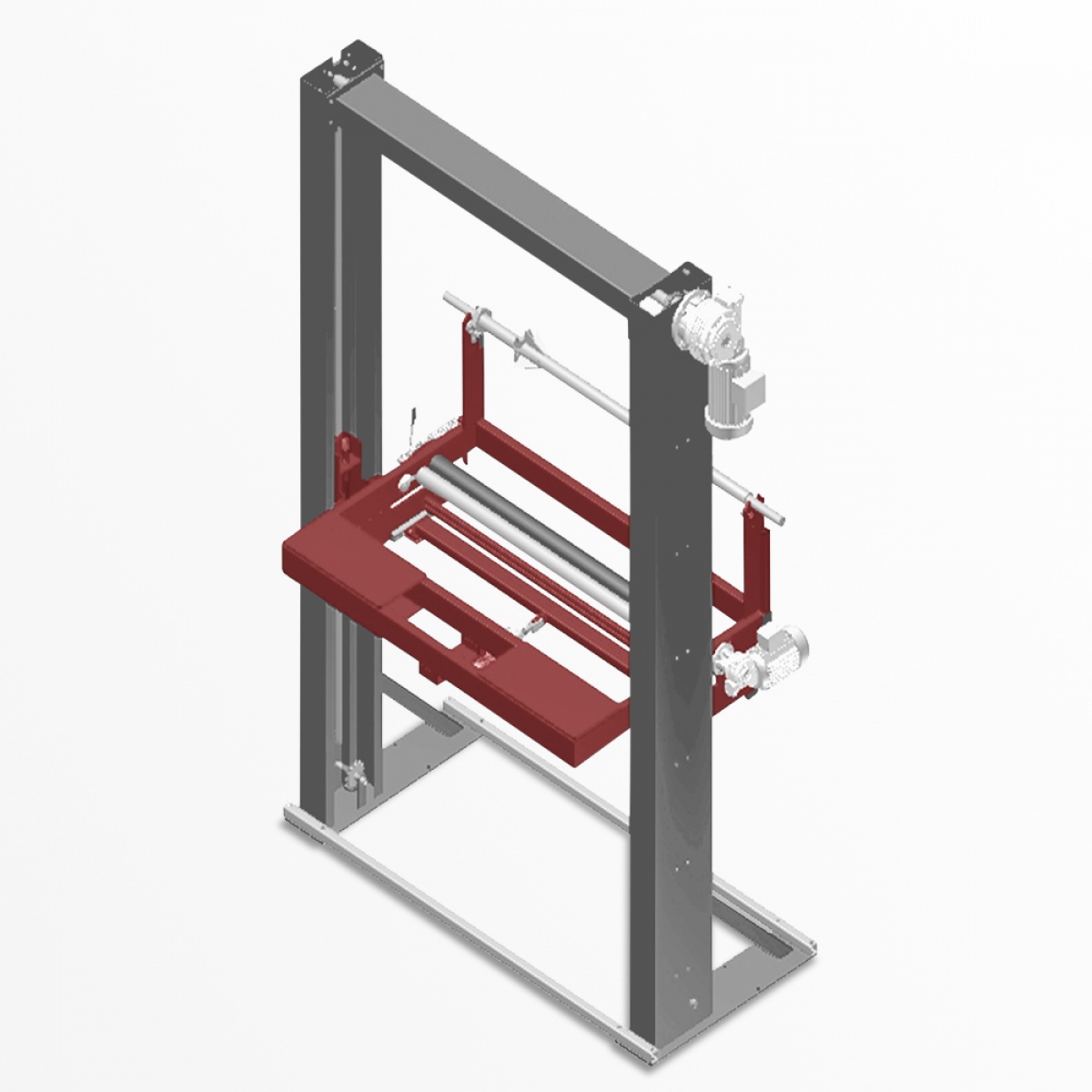

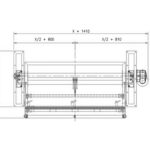

Longitudinal automatic overlay film applicator AARS-M

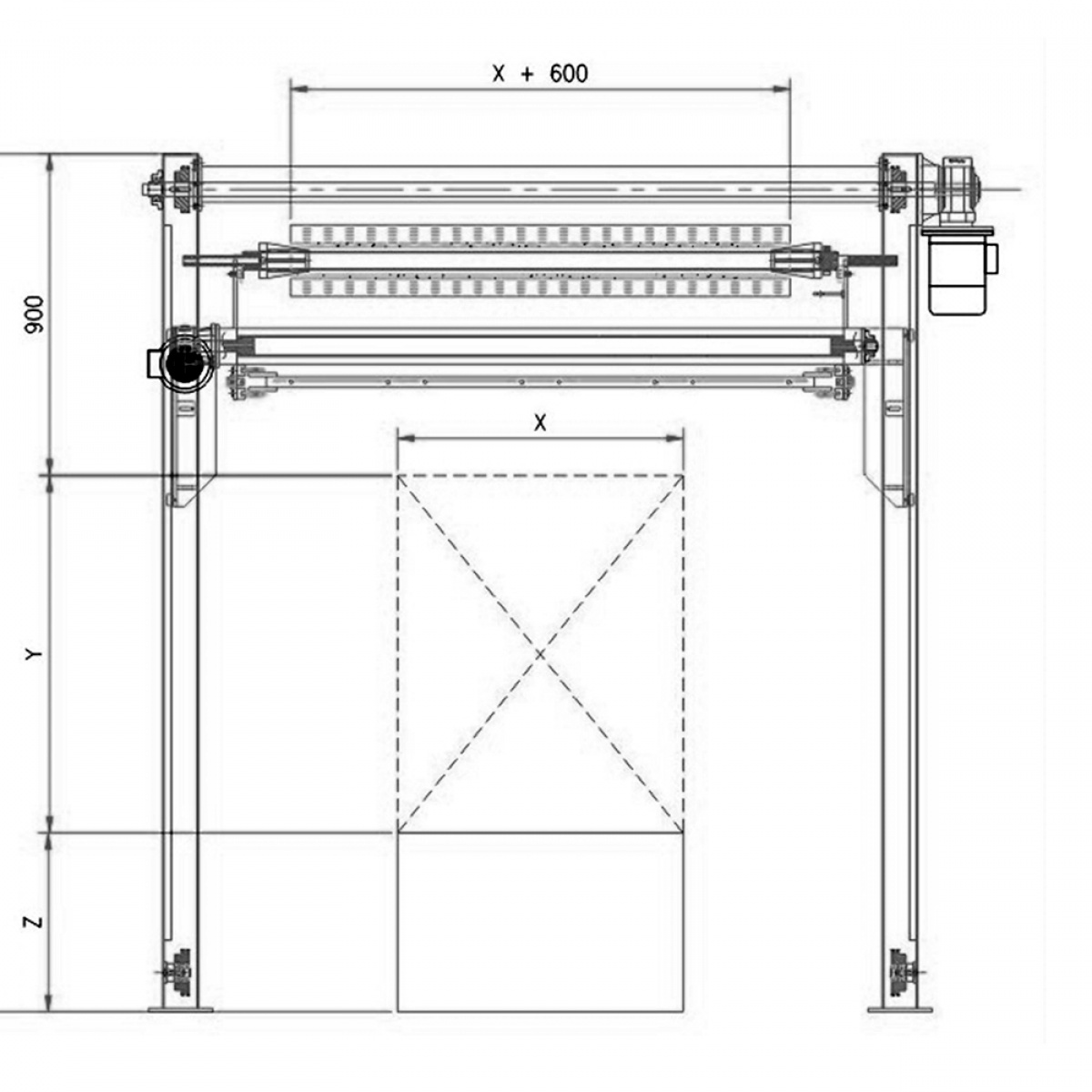

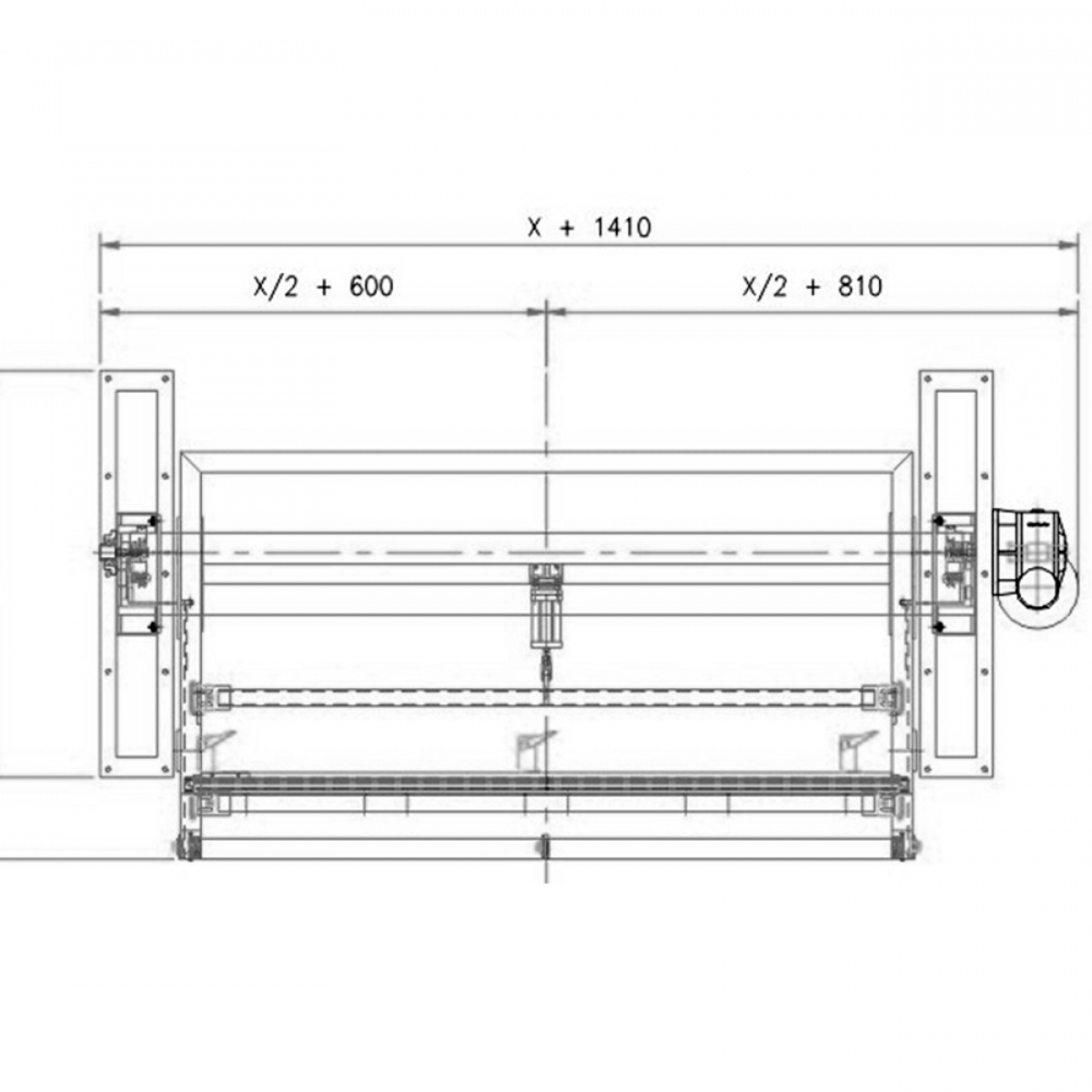

Automatic applicator of overlapping film, jute net, paper or miralon, which is of bridge construction. The machine consists of two steel columns and a cross beam located above the conveyor track. It is designed to be built into the conveyor lines of automatic packaging lines, where it performs the function of automatic pallet overlapping.

Main advantages

- Robust applicator design with long service life.

- Cutting of overlay material by pneumatic motor with steel cutting disc.

- Easy foil replacement.

- Incremental sensors on each motor for precise measurement of blade length and position.

Activity Description:

A horizontal trolley with a roll of film/netting and an independently driven unwinding with a roll of netting/film is moved on the vertical frame. The unwinding of the net/foil is carried out by a motor, after unwinding the required set length of the sheet in millimetres, it is clamped by movable flaps, which are located on two horizontal profiles. The sheet is separated by the transverse movement of a pneumatically driven motor by an innovative cutting unit and a 750 W pneumatic motor at 5 bar with a steel cutting disc. The height of the goods is detected by means of a photocell. The unwinding is equipped with an alarm for end/break of film/mesh. The roll is positioned perpendicular to the axis of movement of the pallets. The machine has mechanical roll centering +/- 50 mm for precise application. It is equipped with FESTO pneumatic components and incremental sensors on each motor for accurate measurement of sheet length and its a position, additionally it is equipped with an anti-spindle sheet for trouble-free unwinding and sheet storage even in open production halls.