High performance for your packaging processes

Key features

- Robust construction for all types of industry

- Fast and precise insertion of the binding tape

- Vibration welding tape

- Continuously adjustable belt tension over a wide range from 50 to 3,500 N

- Programmable control panel with manual control of strapping and wrapping sequences

- 6 to 99 packing cycles stored in memory

- Belt-driven movement of the strapping head of the machine

- PP / PET tape unwrapper

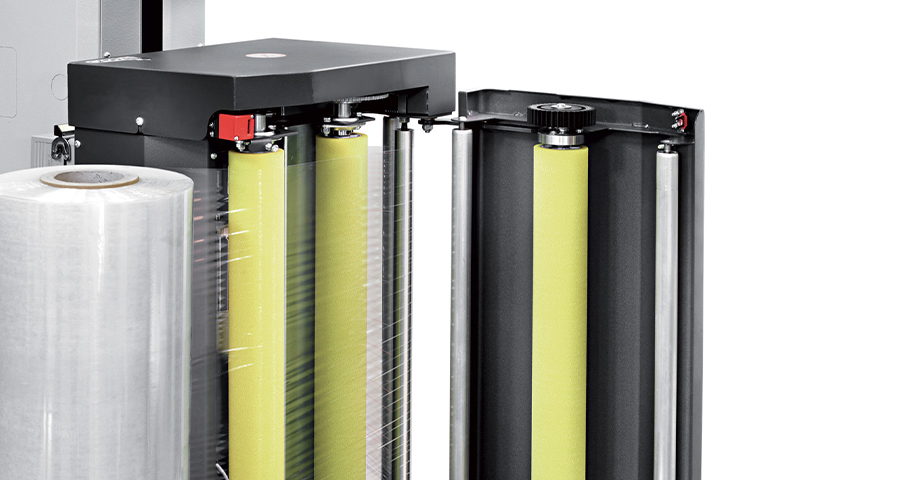

- Long-life pre-stretch film rollers made of polyurethane

- Guaranteed service and spare parts availability

Optional configuration

- Three-stage light indication including low tape indication

- Data bus

- Protective barriers

- Individual colouring according to RAL palette

- Individually designed accessories according to customer needs or shipment dimensions

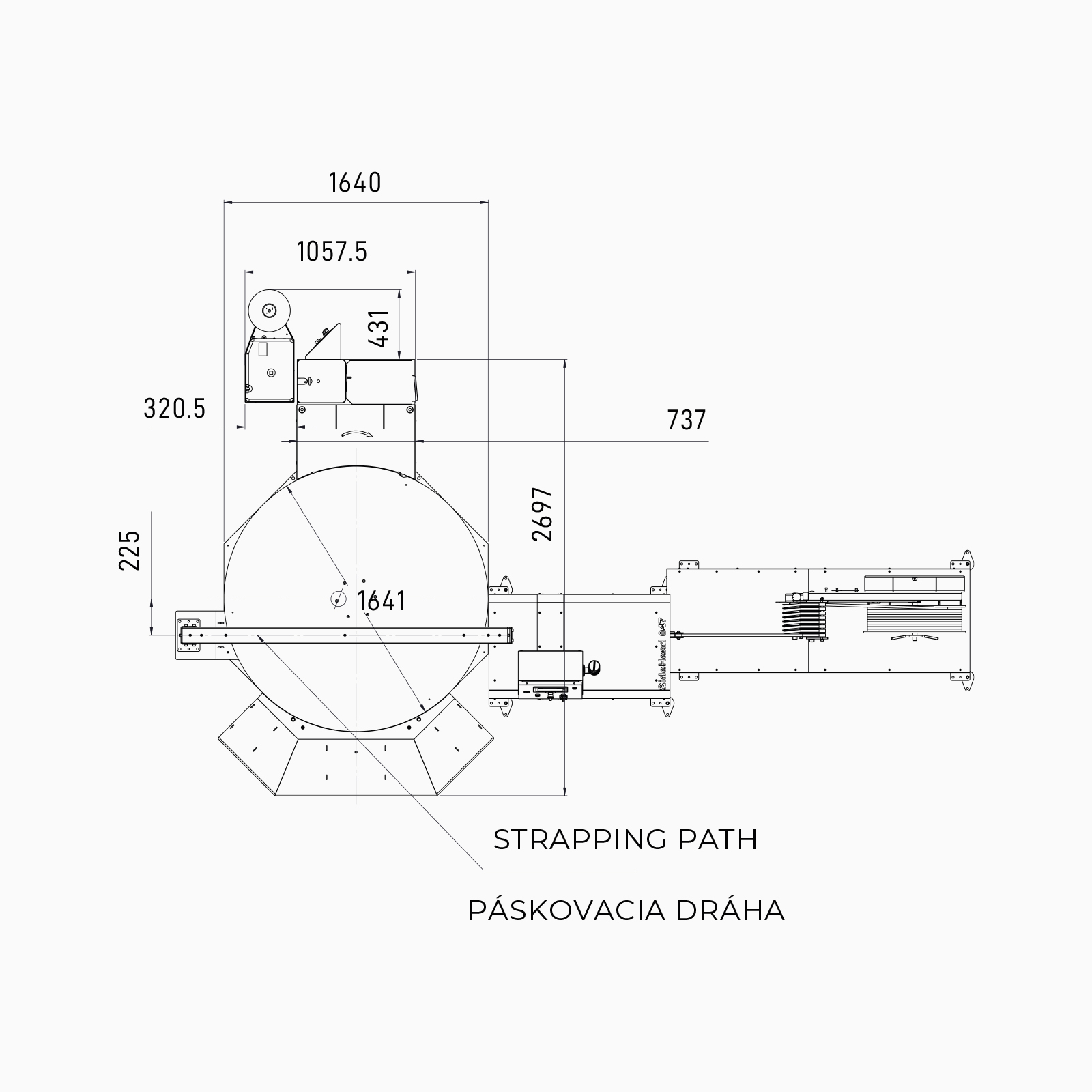

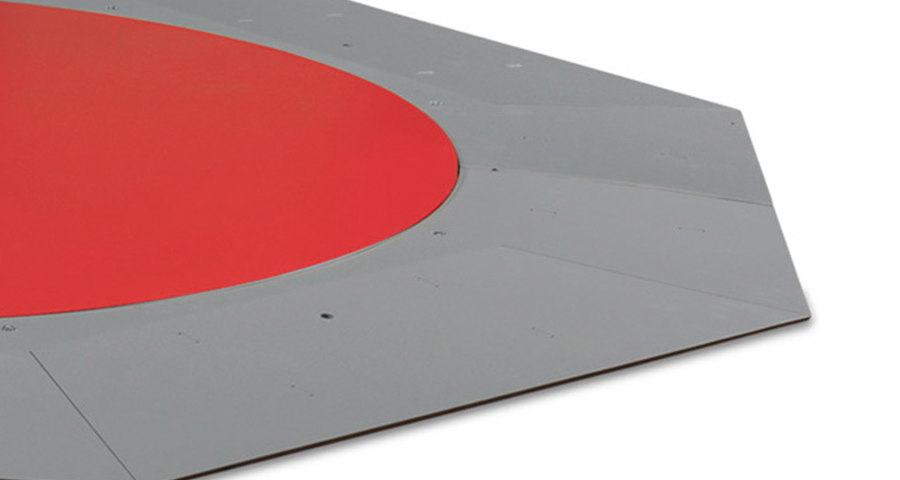

Basic turntable – diameter 1500 to 2200 mm, maximum load capacity 2000 kg, with optional ramp

TRANSPALLET turntable – diameter 1650 to 1800 mm, maximum load capacity up to 1200 kg, with cut-out for pallet truck entry

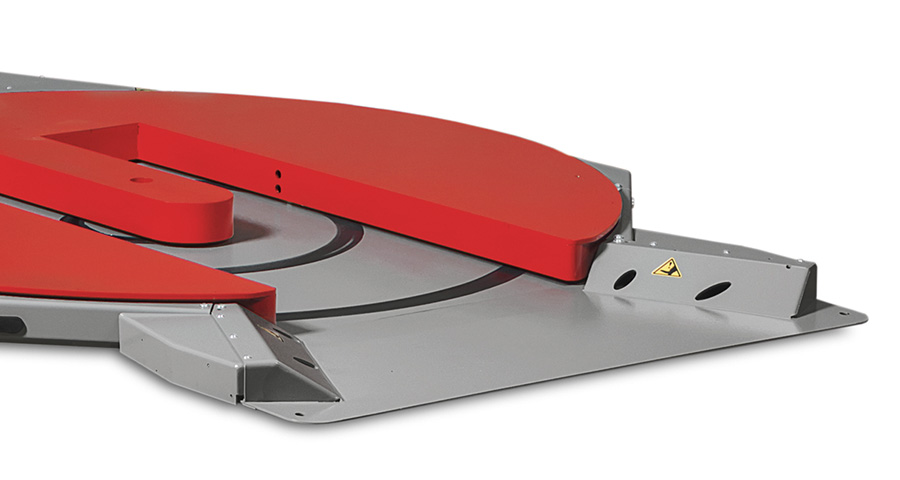

SLIM turntable – with a diameter of 1650 mm, a maximum load capacity of up to 1250 kg and a height of only 25 mm

MB mechanical brake – MB foil trolley with mechanical brake

Electromagnetic brake EB – EB foil trolley with electromagnetic brake

Motorised pre-stretching MPS – MPS film trolley with motorised film pre-stretching, switchable film pre-stretching levels

MPS2 Powerful Motorised Prestretching – MPS2 film trolley with powerful motorised film prestretching, with adjustable film prestretching level

Film applicator ZEPHYR – automatic stretch film applicator on pallet

Stabilization unit – unit with a clamping arm for stabilizing the pallet shipment during packing.

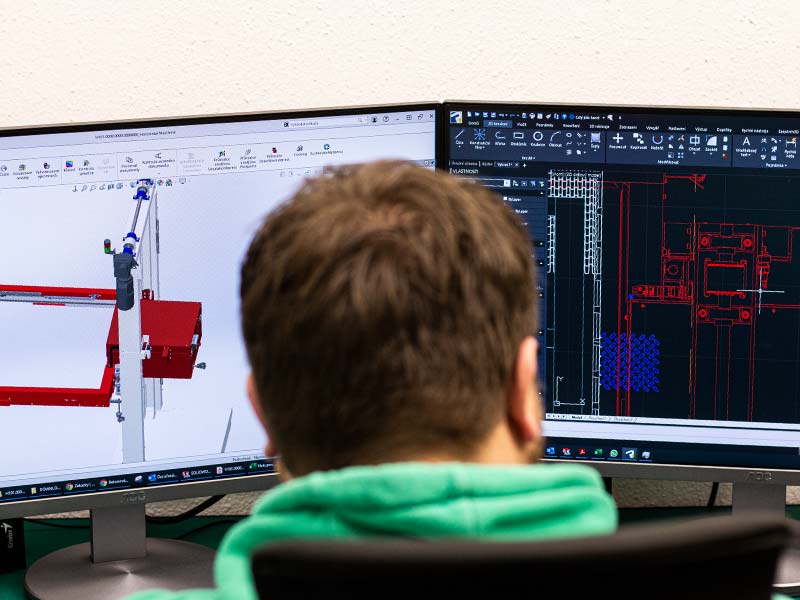

Production of packaging and strapping lines

We manufacture automatic packaging and strapping lines that ensure the preparation of any goods for dispatch in full – application of advertising overlay film, wrapping of the pallet in stretch film, horizontal strapping of the pallet, vertical strapping of the pallet – all this with the incorporation into the network of conveyors, design tailored to your needs and the spatial layout of your premises.

Our packaging technology and strapping machines can be integrated into most production and industrial lines (OMAG, MASA, HESS GROUP, TECHMATIK, QUADRA, AME, REKERS, TERAMEX and others).

Development of packaging technologies and accessories for packaging lines

We are also involved in the development and production of packaging technologies and accessories for special packaging or strapping applications that solve various specific problems related to the nature of the packaged goods, such as:

- automatic film perforator to prevent condensation and protect goods from deterioration during transport or long-term storage,

- a system for applying protective edges to protect fragile goods when strapping on a pallet,

- side or cross press for pressing soft or unstable products before strapping, etc.