Wrapping machine for special wrapping of doors, windows and window frames.

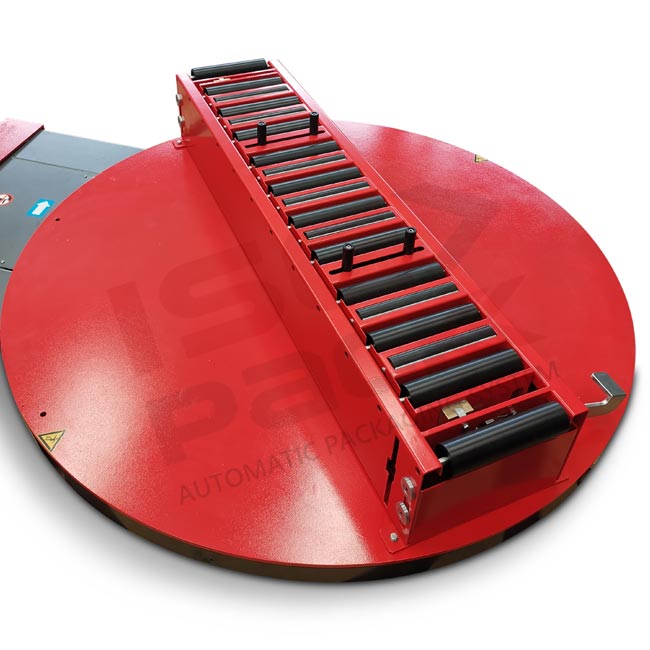

Wrapping machine Easy Wrap 2000 DWC special for wrapping doors, windows and window frames. The machine allows the simultaneous use of bubble wrap/foam and stretch film. The machine has a double mobile pedal control which allows the movement of the top press to be adjusted. The machine is equipped with a roller conveyor with bottom arresting.

General features of the wrapping machine

The Easy Wrap 2000 DWC has a turntable diameter of 1650 mm (standard) and can process products with dimensions d 1650 x w 50/200 x h 2000 mm with a maximum turntable weight of 150 kg. In addition to the possibility of adjusting the number of rotations on the bottom and top of the pallet, it is also possible to set the gradual start-up of the table by means of an inverter. The machine is equipped with a PLC and a 7.2 colour touch screen display which allows up to three different types of product packaging to be set in addition to setting parameters such as carriage ascent and descent speed, photocell reading delay, cycle counter etc.

- Machine construction made of painted steel sheet

- Electric top press

- Film trolley and turntable using a transmission chain

- Machine controlled by PLC and 7,2″ colour touch screen

- Safety stop device on the bottom of the trolley in accordance with CE regulations

- Locking/unlocking brake device for easy hanging of the film on the pallet

- Adjustable top sealing device and roller conveyor with bottom locking system (170 kg)

- Film tensioning by mechanical brake (Easy Wrap 2000 A DWC)

- Motorized preload set at 200% with the possibility of changing the preload ratio 100%, 150%, 250% (Easy Wrap 2000 B DWC)

- Automatic film cutting at the end of the cycle (Easy Wrap 2000 B DWC)

- Emergency stop in accordance with CE regulations

- CE compliant reset button

- Front and rear openings for forklift

- Inverter for slow start and indexed turntable stop

- Cycle counter

- Manual working mode of the machine

Parameters adjustable via control panel

- Number of laps on the bottom of the pallet (starting cycle)

- Number of rounds at the top of the pallet

- Number of rounds at the bottom of the pallet (at the end of the cycle)

- Speed adjustment from 0 to 12 rpm

- Adjusting the rising speed of the trolley

- Adjusting the descending speed of the trolley

- Adjustable number of ascending and descending cycles

- Adjustable indexing time of the rotary plate

- Adjustable photocell delay

- Adjustable film cutting parameters (Easy Wrap 2000 B DWC)

- Switching on/off the automatic cutting film (Easy Wrap 2000 B DWC)

Cycles activated by the control panel

- Ascending and descending cycle

- Ascending cycle only

- Amplification cycle at programmed altitude (climb cycle, rise/fall cycle)

- Altimeter cycle (pallet height adjustment) to detect pallet without photocell

- Upper leaf cycle (ascending/descending)

- N° 10 programmable cycles by touch screen according to product/package

Characteristics of the processable product

- Max product dimension: l. 1650 x w. 50-200 mm.

- Useful height: 2000 mm.

- Maximum product weight: 100 kg.

Features stretch film

-

Outer diameter of the foil roll: 280 mm.

-

Inner diameter of the foil roll: 76 mm.

-

Height of the film roll: 500 mm.

-

Maximum winch weight: 16kg.