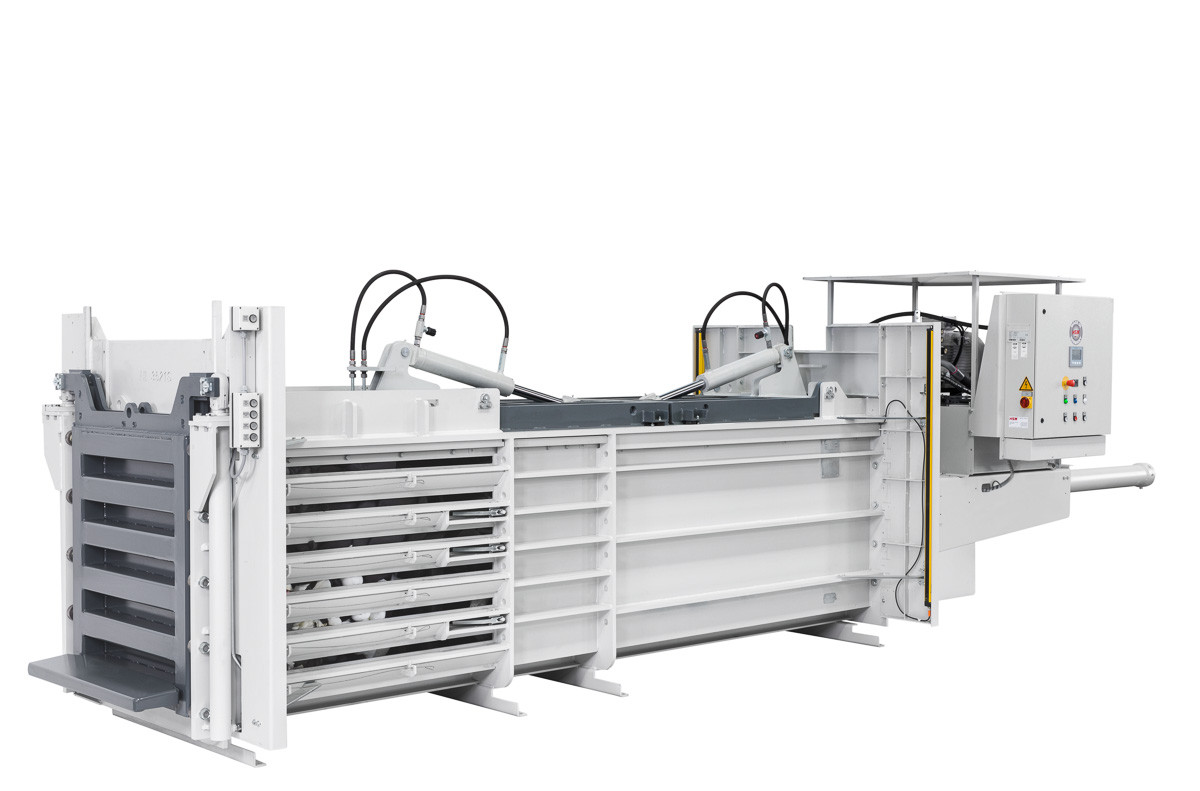

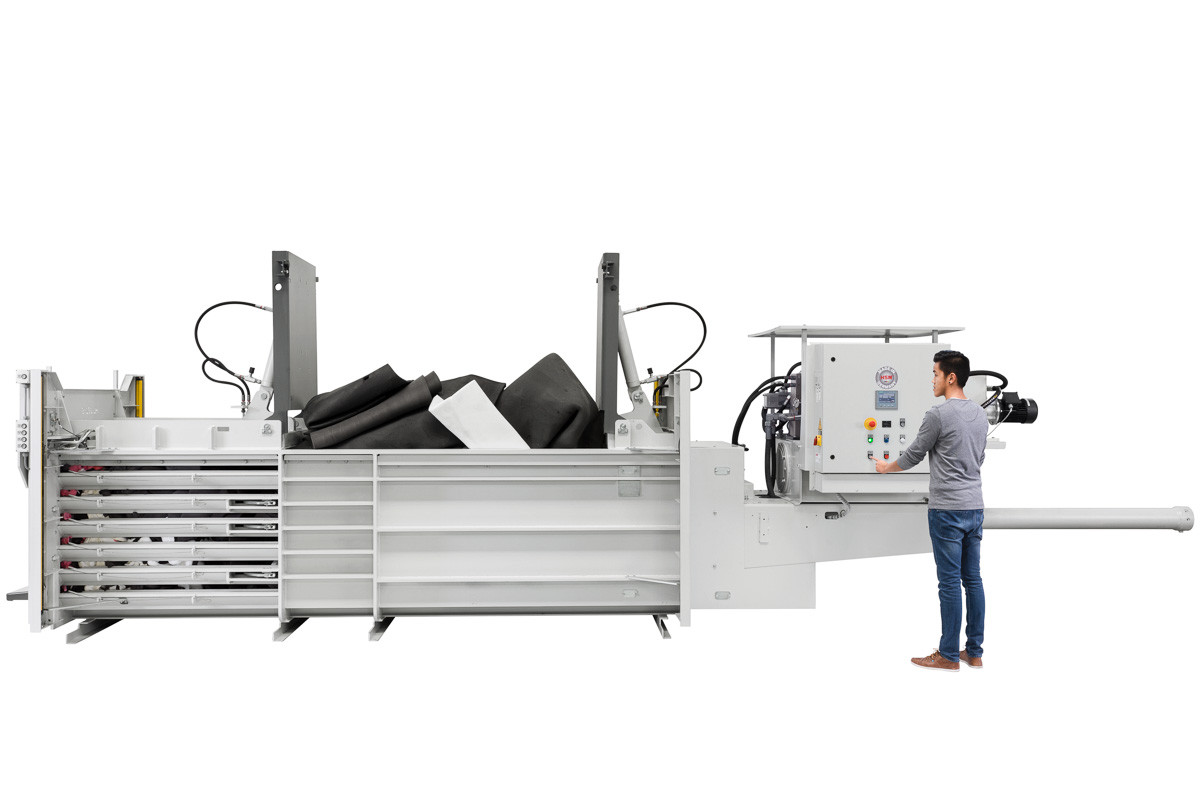

HSM HL 3521 S horizontal bale baler

The HSM HL 3521 S with its exceptionally large loading opening is the perfect machine for pressing large quantities of paper, cardboard, film or packaging material and for extremely large and bulky materials. It has also been specially designed for squeezing heavily expanding material such as foam.

- Compression of bulky materials. Suitable for: cardboard, foil, foam, polystyrene, hollow containers, metal buckets, barrels and much more

- Secure the work area with infrared light curtains for maximum operator safety

- Suitable for continuous loading with conveyor belt or similar

- Extremely large loading opening allows easy and convenient loading

- Hydraulic counterweight for bale removal ensures optimum operator comfort and safety

- Hydraulic loading flap for maximum operator comfort

- Multilingual operating guidance and PLC with stored program

- The unique design and operable positioning of the ram press allows for easy cleaning and servicing

- Manual bale strapping with Quick-link wire

Key features

- High pressing force: The HSM HL 3521 S provides excellent compacting force, which enables large volumes of waste to be compacted into compact and solid bales, optimising storage and transport.

- High capacity: this press is designed to process large quantities of material, making it ideal for demanding industrial applications and recycling operations.

- Automated process: the model is equipped with an advanced automatic system that simplifies operation and increases the efficiency of the compaction process. Automatic material feeding and binding saves time and reduces the need for manual intervention.

- Robust construction: the HSM HL 3521 S is made of high-quality and durable materials, ensuring long service life and reliable operation even under intensive use.

- Energy efficiency: modern technologies reduce energy consumption, which contributes to lower operating costs.

- Safety features: the press is equipped with various safety systems, including an emergency stop switch and protective covers to ensure safe operation and operator protection.

Benefits

- Cost optimisation: high compaction capacity and efficiency lead to significant reductions in waste storage and transport costs.

- Ecological solution: compacting the waste contributes to better use of storage and transport capacity and reduces the ecological burden.

- Increase productivity: automated functions increase productivity and allow employees to focus on other important tasks.

- Robustness and long life: quality components and robust construction ensure long life and trouble-free operation even in harsh industrial environments.

The HSM HL 3521 S is a powerful horizontal baler that provides an efficient solution for compacting large volumes of waste. Its high capacity, automated features and robust design make this model ideal for demanding industrial and recycling applications where efficient and reliable waste management equipment is required.

Procedure

The use of the HSM HL 3521 S horizontal baler involves several steps that ensure efficient and safe compaction of waste. The following is a step-by-step procedure for the proper use of this equipment:

1. Preparation before use

Operator training: ensure that all press operators have been properly trained in its use and are familiar with all safety regulations. Inspection of the equipment: check that the machine is in good working order. Verify that all safety guards are in place and functional. Connection to power: Ensure that the machine is properly connected to the electrical supply and that all connections are secure.

2. Preparation of material

Collection and sorting of material: Ensure that all material to be compacted is properly sorted. This compactor is designed to process paper, cardboard and plastics. The material should be free of metal objects and other debris. Cutting large pieces: if the pieces of material are too large, it is a good idea to cut or tear them into smaller pieces to ensure efficient compaction.

3. Press operation

Inserting the material: open the feed opening and insert the material into the press. Make sure the material is evenly distributed and does not fill only one side of the feeder. Parameter setting: If necessary, adjust the press parameters according to the type and quantity of material to be compacted. This step may include setting the compression force and other parameters. Starting the compactor: activate the machine using the control panel. The baler will automatically start to pull in the material, compress it and bind it into a bale. Process Monitoring: Monitor the compaction process to make sure everything is running smoothly. Take care of manual intervention or maintenance if necessary.

4. After the process is complete

Picking a bale: When the compaction cycle is complete, the bale is automatically ejected. Open the outlet opening and remove the finished bale. Bale Binding: If the machine does not perform automatic binding, manually bind the bale as required. Bale storage: store the bale in a designated location for further processing or removal. Maintenance: After each use, perform maintenance according to the manufacturer’s instructions. This may include cleaning the machine, checking the oil, and other maintenance tasks.

5. Precautions

Follow the safety instructions:Follow all safety instructions in the equipment manual. This includes wearing protective equipment and following safety rules when working with electrical equipment. Emergency Stop: In the event of an emergency, use the emergency stop switch to stop the press immediately. Regular inspection: Regularly check all safety and operating systems of the baler to avoid the risk of accidents or damage.