Semi-automatic packaging machine PKG SMARTWRAP

Automatic introduction, cutting and sealing of the film

PKG SMARTWRAP is a semi-automatic packaging machine, but its automated functions will simplify the operator’s work as much as possible. The operator only needs to place the palletized shipment on the turntable of the machine and activate the packaging process. The wrapping machine autonomously introduces the stretch film onto the palletised shipment. After complete wrapping with the selected program, it automatically cuts and seals the film to prevent it from unwinding by itself.

Activation of the pallet pack by remote control

The packaging process can be easily activated by the operator by remote control directly from the forklift, immediately after the shipment is loaded onto the turntable. The PKG SMARTWRAP packaging machine can be equipped with one of three film carriages according to the method and performance of the film pre-stretching (EB, MPS, MPS2), or with additional accessories to adapt to the packaging requirements.

Key features

- Photocell for shipment height detection,

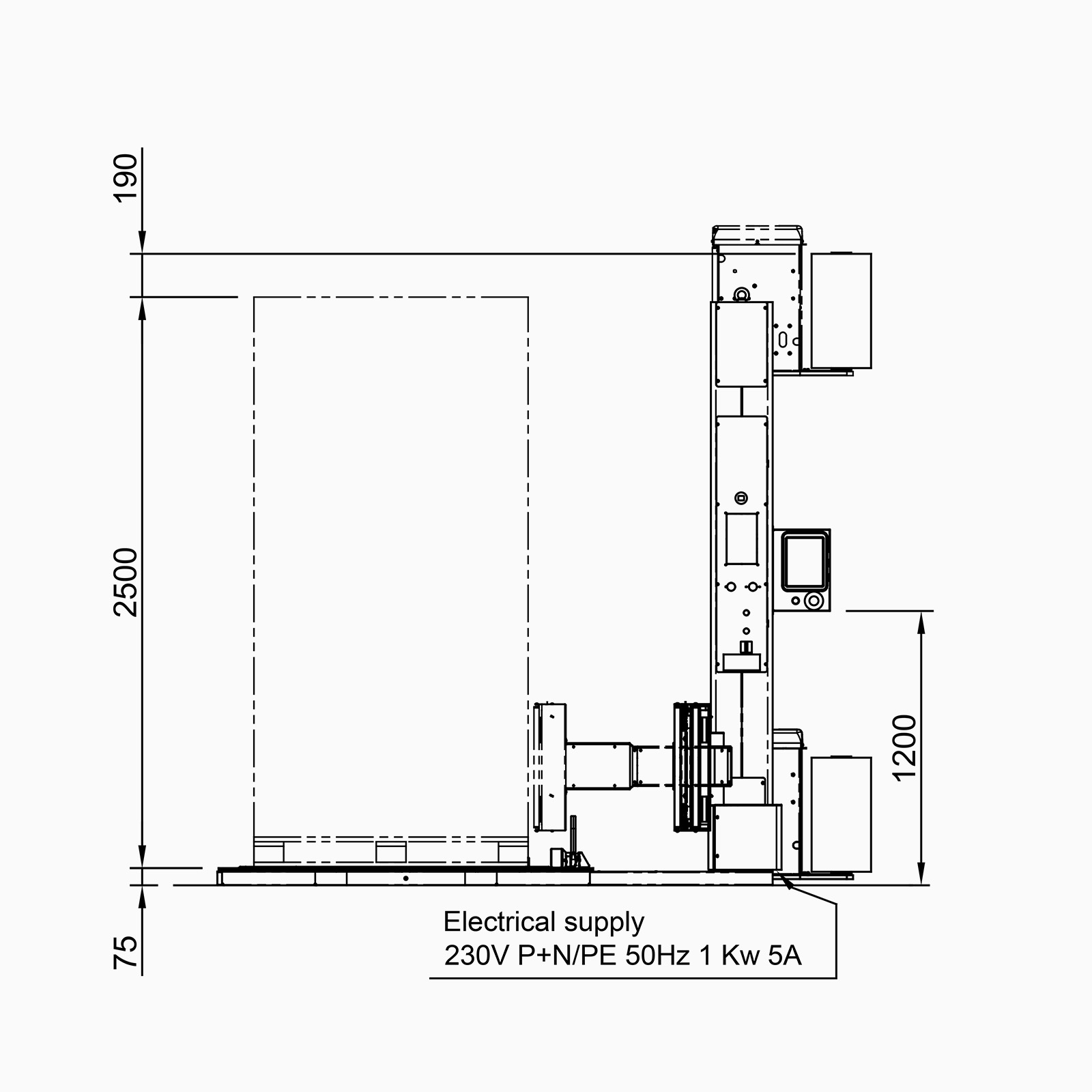

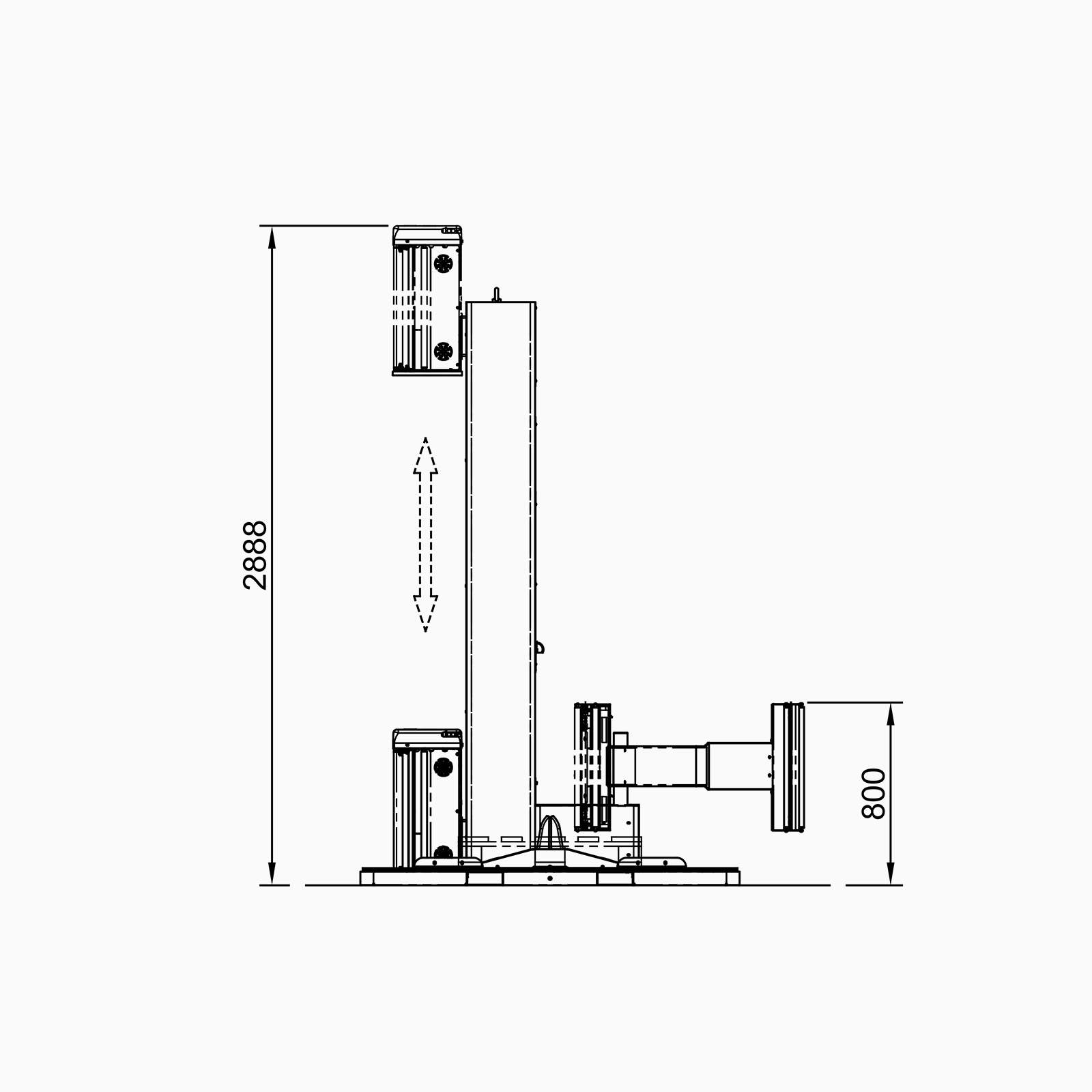

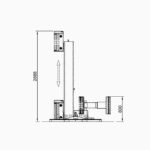

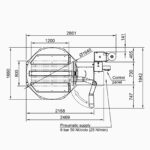

- Standard max. shipment height 2200 mm,

- Audible indication of machine status,

- Handling holes for forklift,

- Keypad lock,

- Improved automatic system for automatic insertion, cutting and sealing of stretch film,

- Packing zone protected by photocells, emergency button to stop the packing process.

Package parameters adjustable from the control panel

- Turning speed of the turntable,

- Lift/lower speed of the film trolley,

- The number of packages on the top of the pallet shipment / on the bottom of the shipment (photocell scanning delay),

- Film tensioning upwards / downwards / upwards / downwards,

- Foil tensioning ratio upwards / downwards / upwards / downwards (only valid for MPS2 trolley),

- Reinforced wrapping in preset height with the possibility of regulating the number of wraps,

- Activate/Deactivate film cutting

Choice of packaging type:

- Automatic packing,

- Semi-automatic packaging,

- Pack up/down,

- Pack up only / Pack down only,

- Application of the top overlapping foil,

- Packing for high stability of the shipment,

- Ergonomic packaging with easy film clamping.

Configuration options

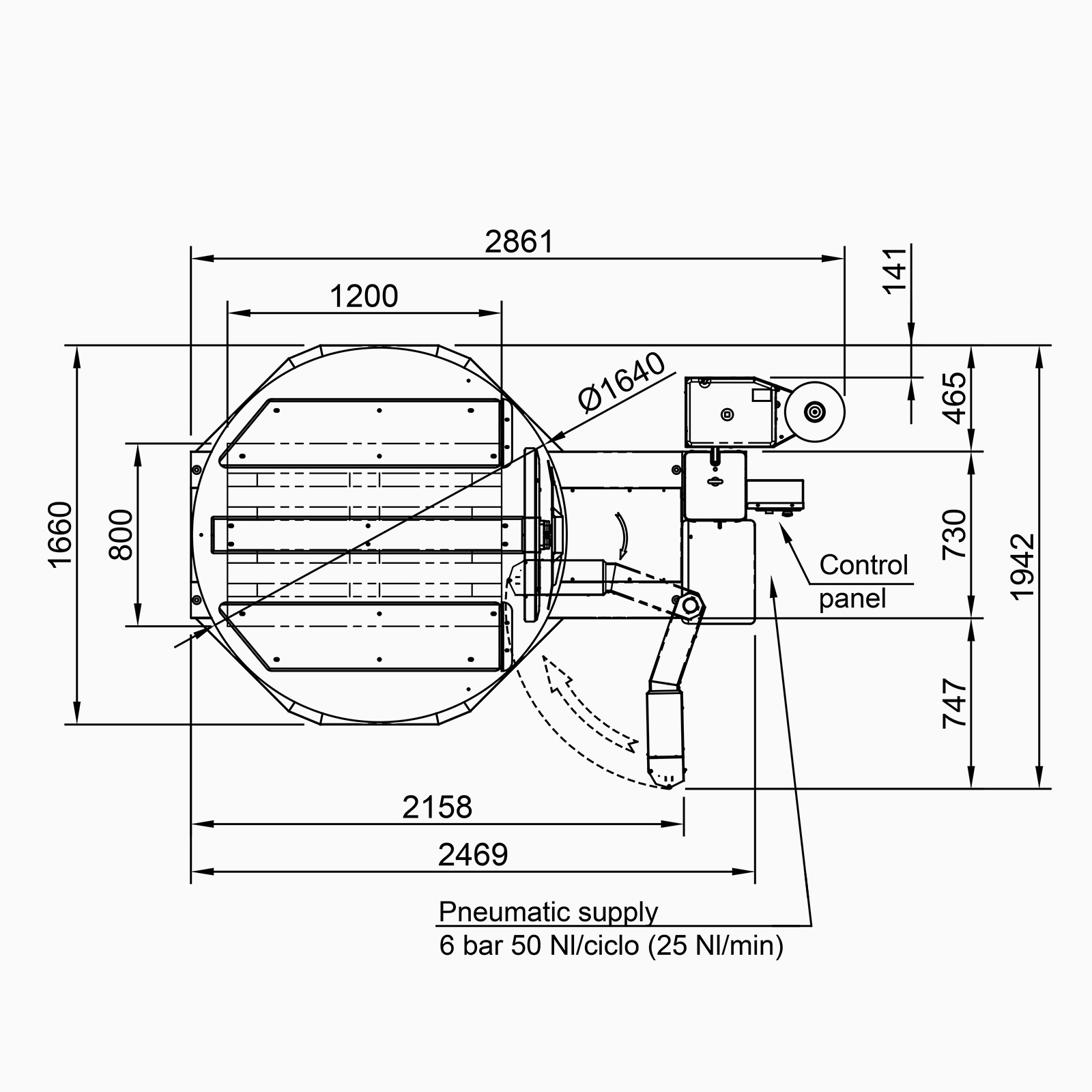

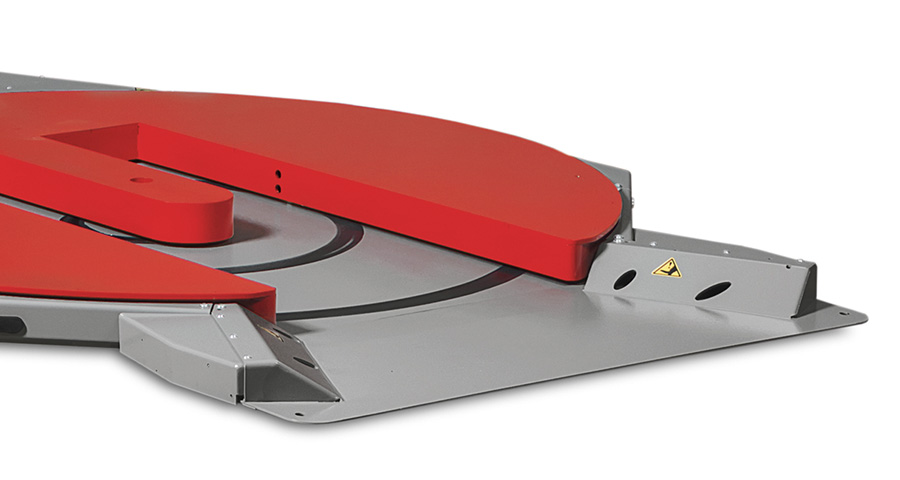

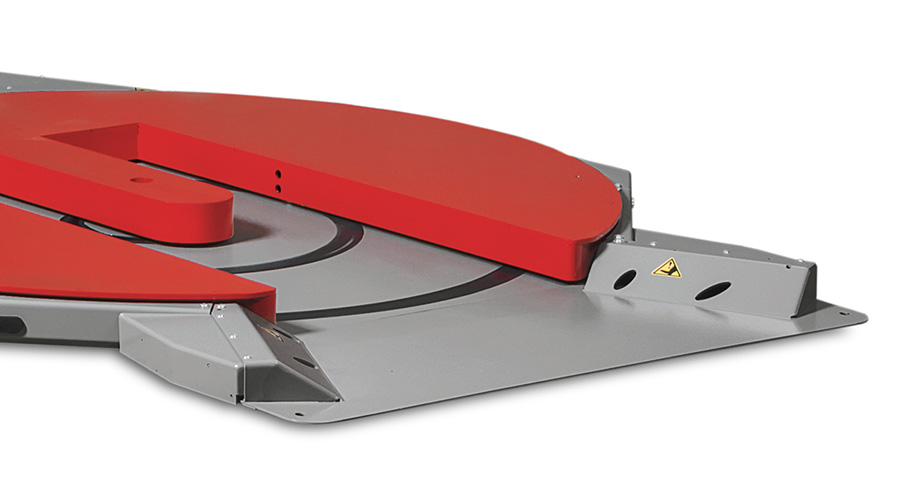

Basic turntable – diameter 1500 to 2600 mm, maximum load capacity 2000 kg, with optional ramp

TRANSPALLET turntable – diameter 1650 to 1800 mm, maximum load capacity up to 1200 kg, with cut-out for pallet truck entry

Stabilization unit – unit with a clamping arm for stabilizing the pallet shipment during packing

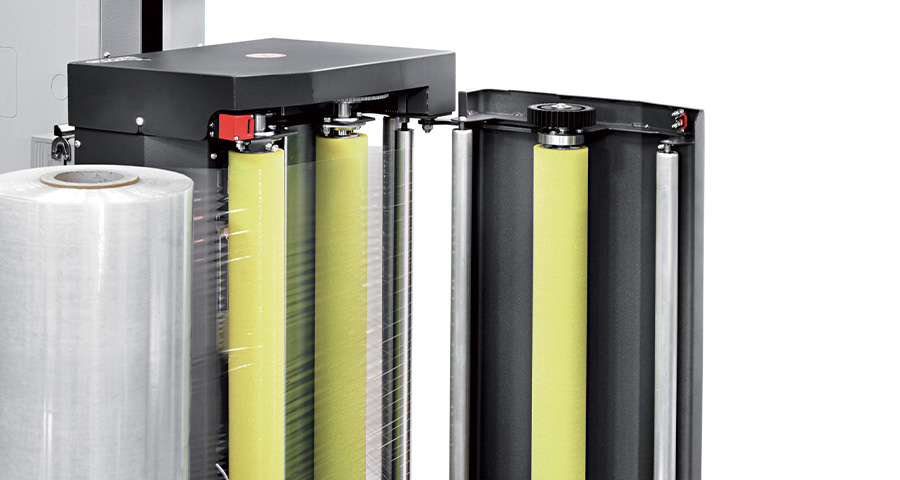

Motorised pre-stretching MPS – MPS film trolley with motorised film pre-stretching, switchable film pre-stretching levels

MB mechanical brake – MB foil trolley with mechanical brake

MPS2 Powerful Motorised Prestretching – MPS2 film trolley with powerful motorised film prestretching, with adjustable film prestretching level

Automatic strapping – additional unit for the film trolley for automatic strapping of the consignment