The TP-202 benchtop taping machine ensures perfect fixation of your products by taping.

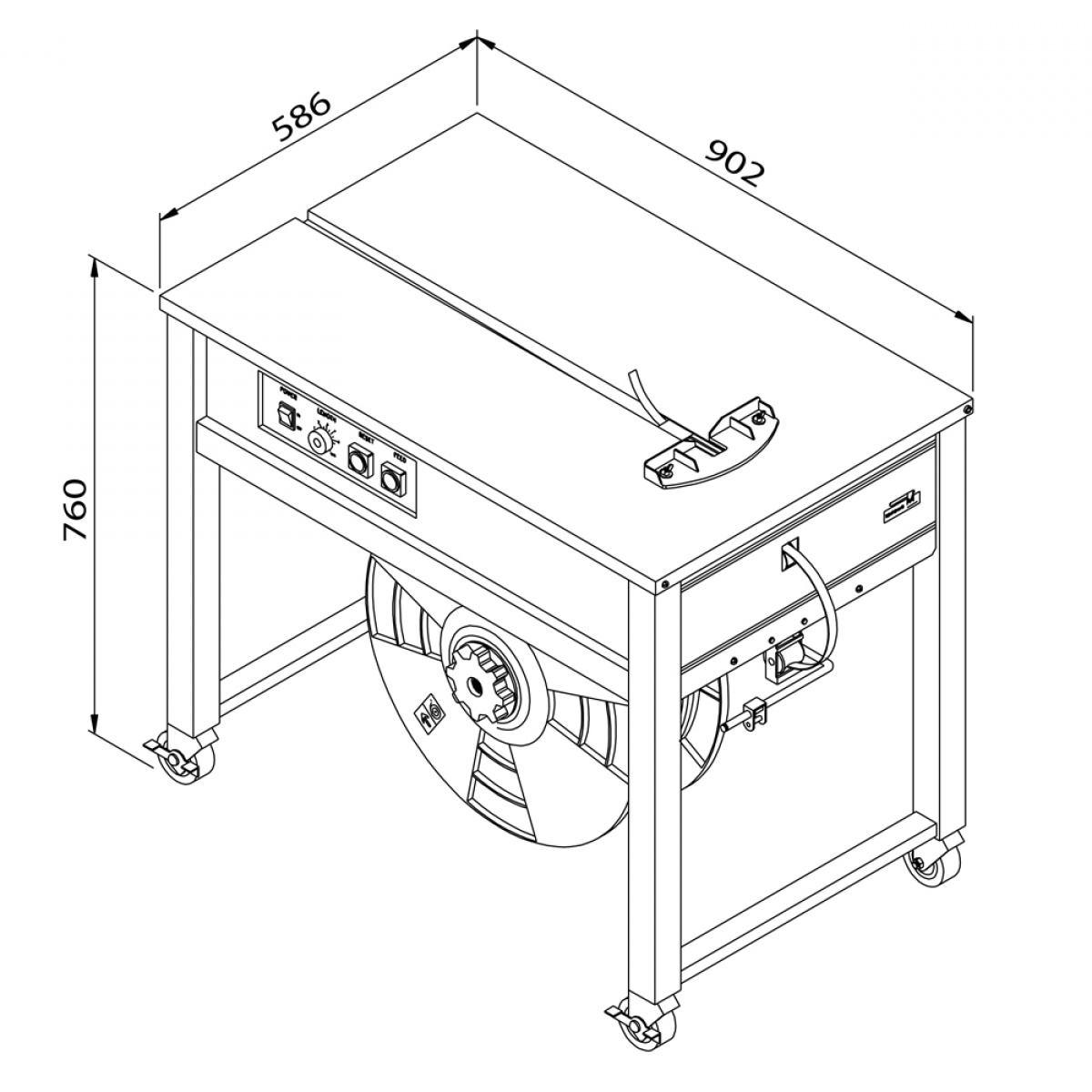

The TP-202 is a semi-automatic benchtop tape machine with manual tape loading. The PP binding tape is connected by a heat weld from the underside of the item to be taped. The strapping machine is mobile and can be easily moved to the desired location even during operation. The frameless design allows for taping any object that can be placed on the taping machine’s work plate. The TP-202 strapping machine is suitable for operations with basic requirements. The TP-202 is popular for its reliability and competitive price. The TP-202 strapping machine is GS and CE approved.

Main advantages:

- easy operation

- electronic regulation of the length of the ejected tape

- mechanical regulation of tape tension

- simple construction from durable materials

- stainless steel worktop that is not restricted by the frame

- advantageous price and reliable operation

Description of the function and use of the taping machine

Place the packaged product on the machine worktop. Manually wrap the tape around the product and insert it into the hole in the worktop. As soon as the machine detects the tape, it starts to tighten it with the preset force. The machine then welds, cuts and ejects the preset length of tape for the next tape cycle.

Control panel of the TP-202 tape machine

- main switch 0-I

- regulation of the length of the ejected binding tape “LENGHT”

- cutting off the tape or faulty “RESET” patching

- quick ejection of the “FEED” binding tape

- Tape tightening force regulation – by a wheel in the rear part of the tape machine