Economical sealing for large operations

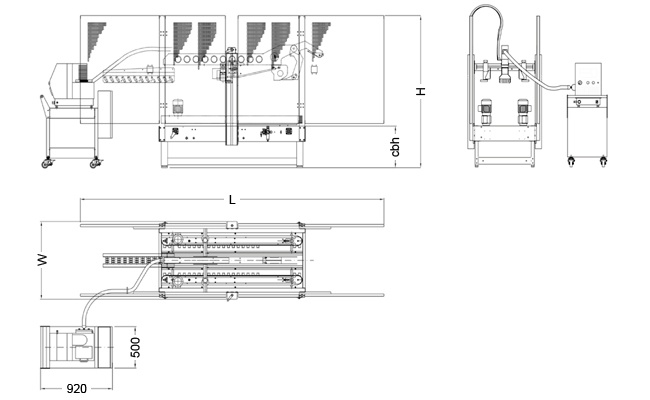

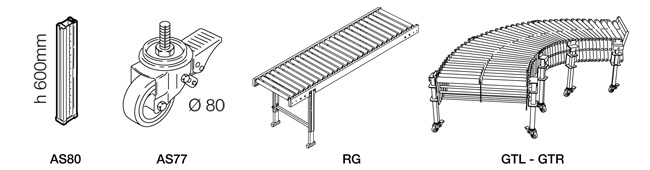

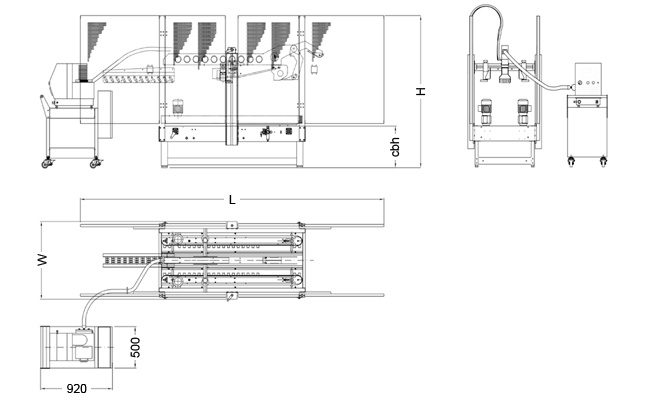

The automatic gluing machines of the SIAT HM11-T/TB model series ensure the gluing of cartons with HOT-MELT liquid glue. Cartons are glued from the top side (SIAT HM11-T) or simultaneously from the top and bottom side (SIAT HM11-TB). The HOT-MELT taping technology is ideal for large-scale operations where its use achieves significant savings compared to taping with adhesive tape.

TIP: Consult with us your request packaging technology and we will recommend the best solution for your needs.

Models on offer

- SIAT HM11-T – Automatic carton sealing machine with HOT-MELT liquid adhesive technology, sealing cartons from the top side.

- SIAT HM11-TB – Automatic carton sealing machine with HOT-MELT liquid adhesive technology, simultaneous sealing of cartons from top and bottom side.

Key features

- Easy manual adjustment of carton dimensions.

- Side handling belts 2x 75mm for moving cartons through the machine (electric drive 2x 0,18 kW).

- Carton sealing with HOT-MELT technology:

-

- Top flaps of cardboard(SIAT HM11-T),

- Simultaneous top and bottom flaps of cardboard(SIAT HM11-TB).

- Economical sealing method, protective function – easy identification of broken packaging.

- ROBATECH® sealing unit with 5 kg filling hopper and easy dosing (alternative unit manufacturer on request).

- Adjustable working height of the machine.

- Quality and robust construction.

- High efficiency of the sealing process – 1000 to 1200 cartons / hour.

- Control panel with the possibility to configure different sealing programs – Different parameters for preheating and glue dispensing quantity.

- Photocell controlled passage of cartons through the machine.

- OMRON PLC control unit .

- Safety fuse for disconnection of electronic and pneumatic circuits.

- SIAT devices are certified according to EU directives.