Wrap pallet shipments in film at the lowest cost

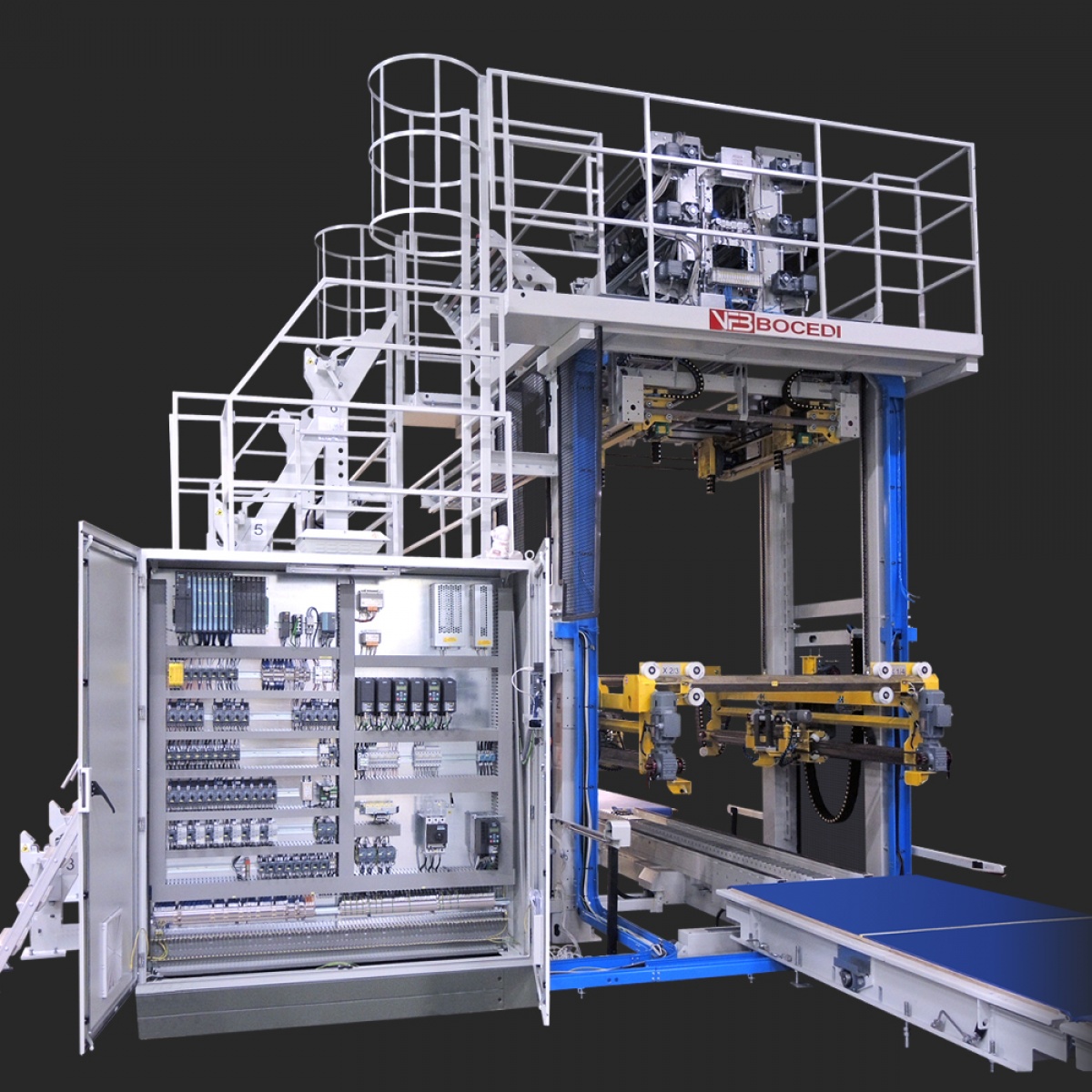

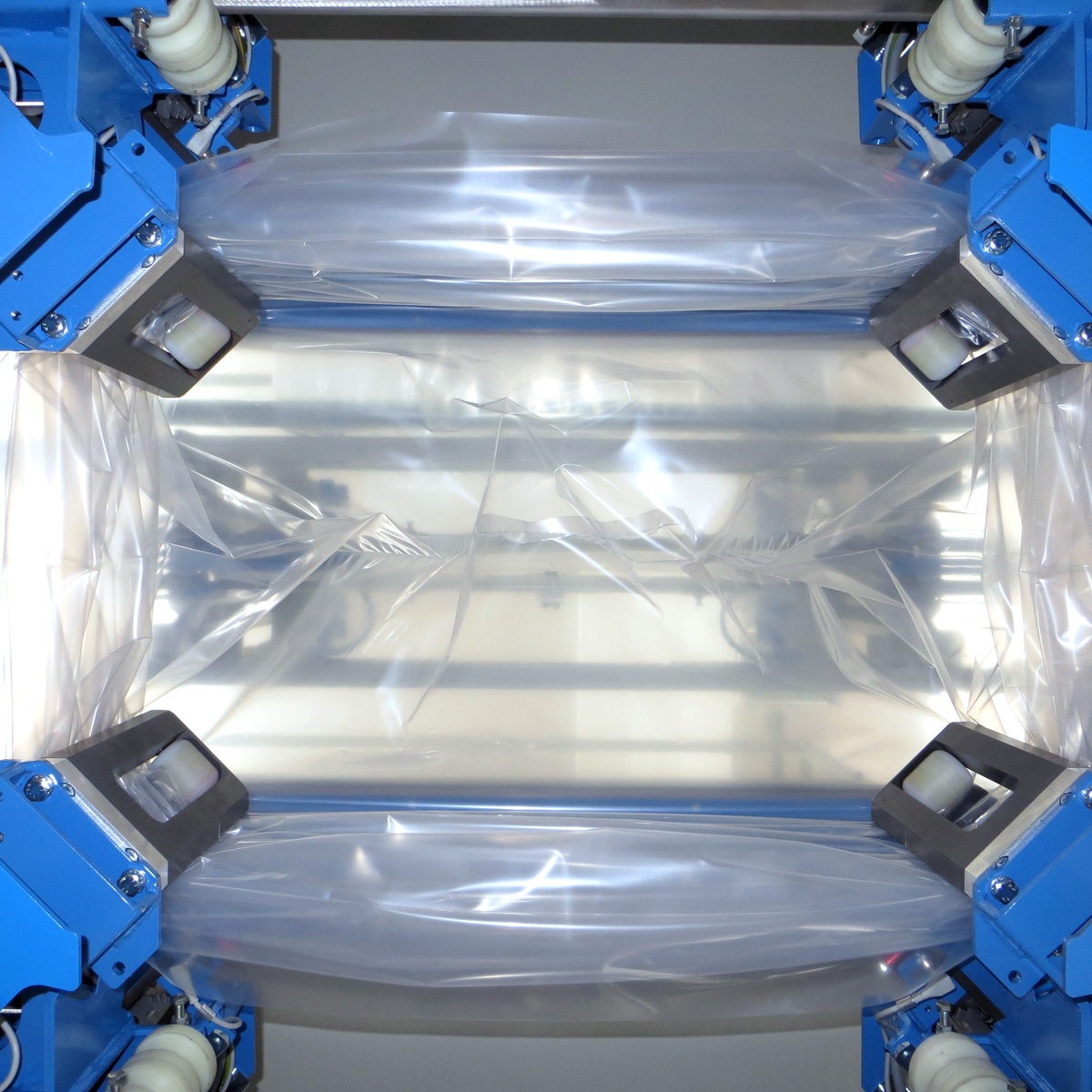

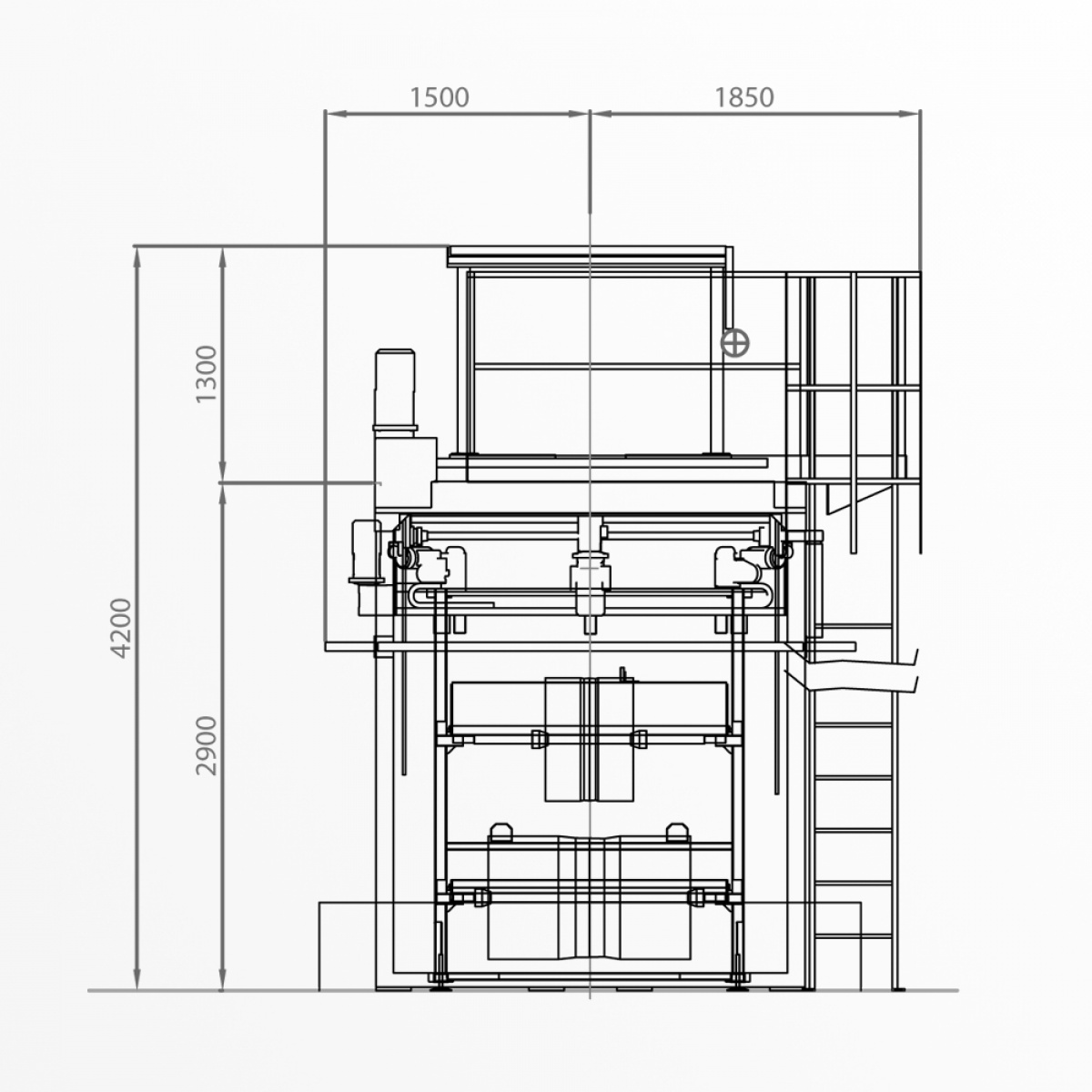

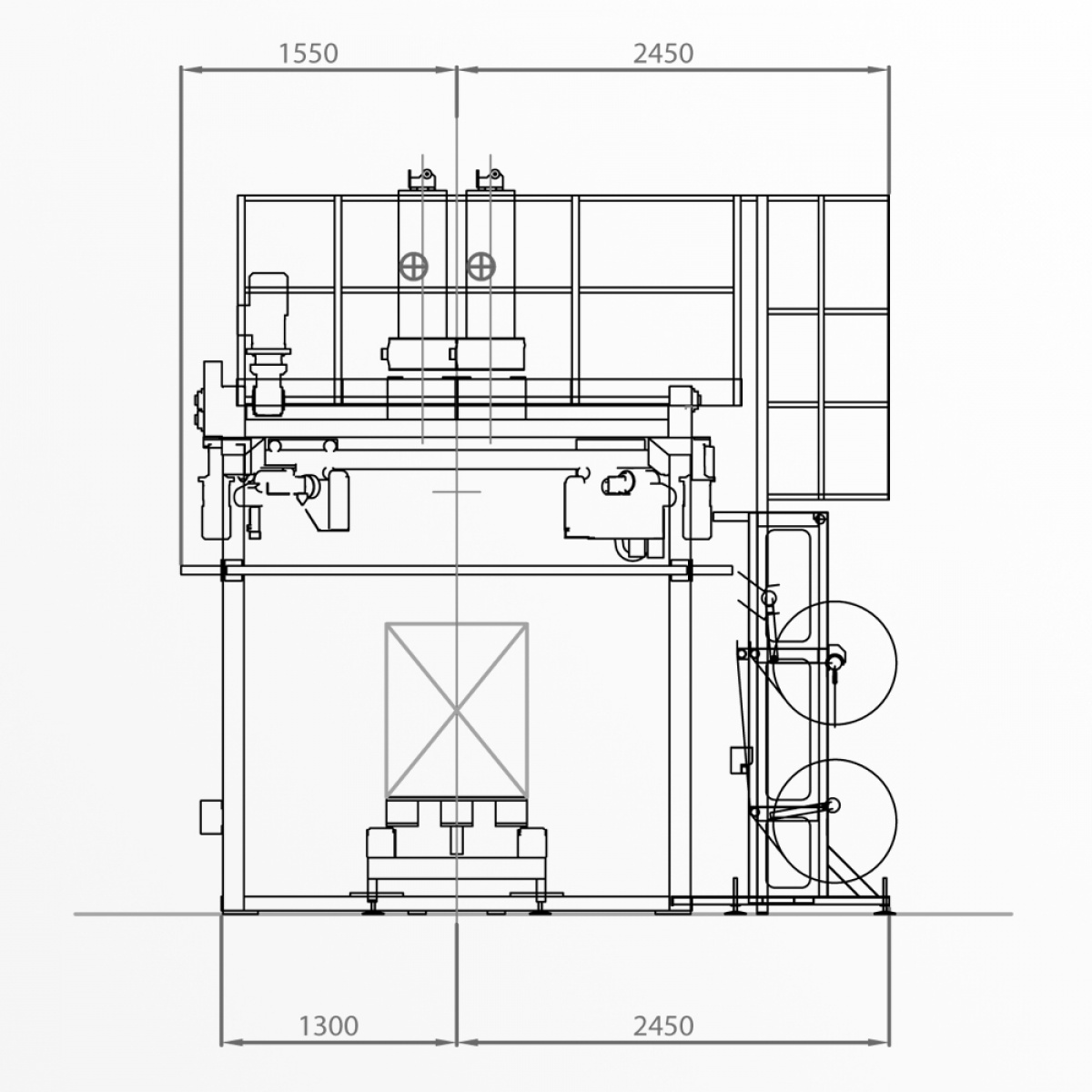

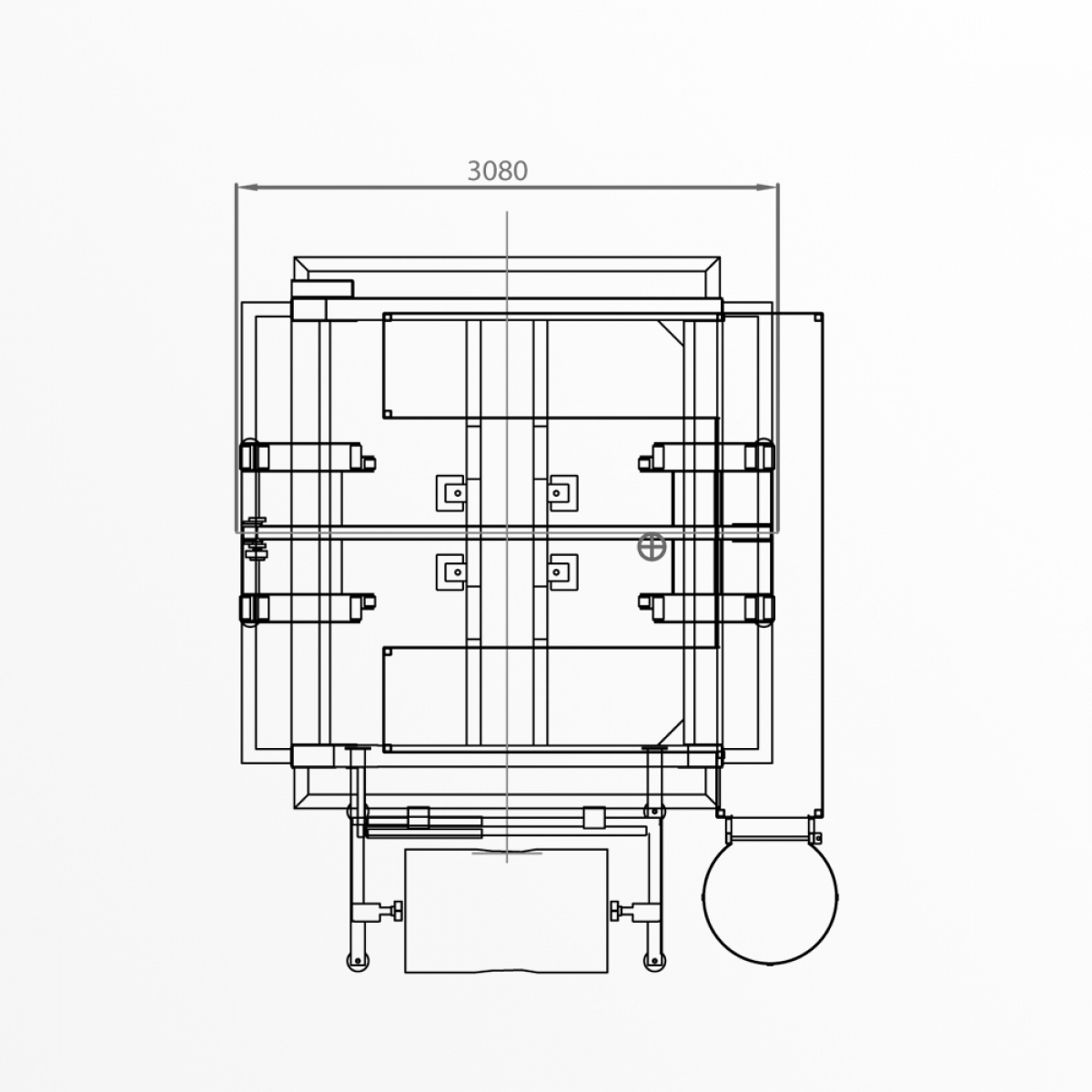

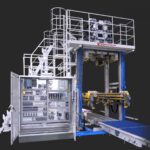

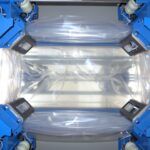

The Stretch Hooder FB1000 offers automatic packaging of pallet shipments using stretch hood film (film in the form of a bag), which is mechanically stretched when applied to the pallet shipment.

Up to 80 packed pallets per hour

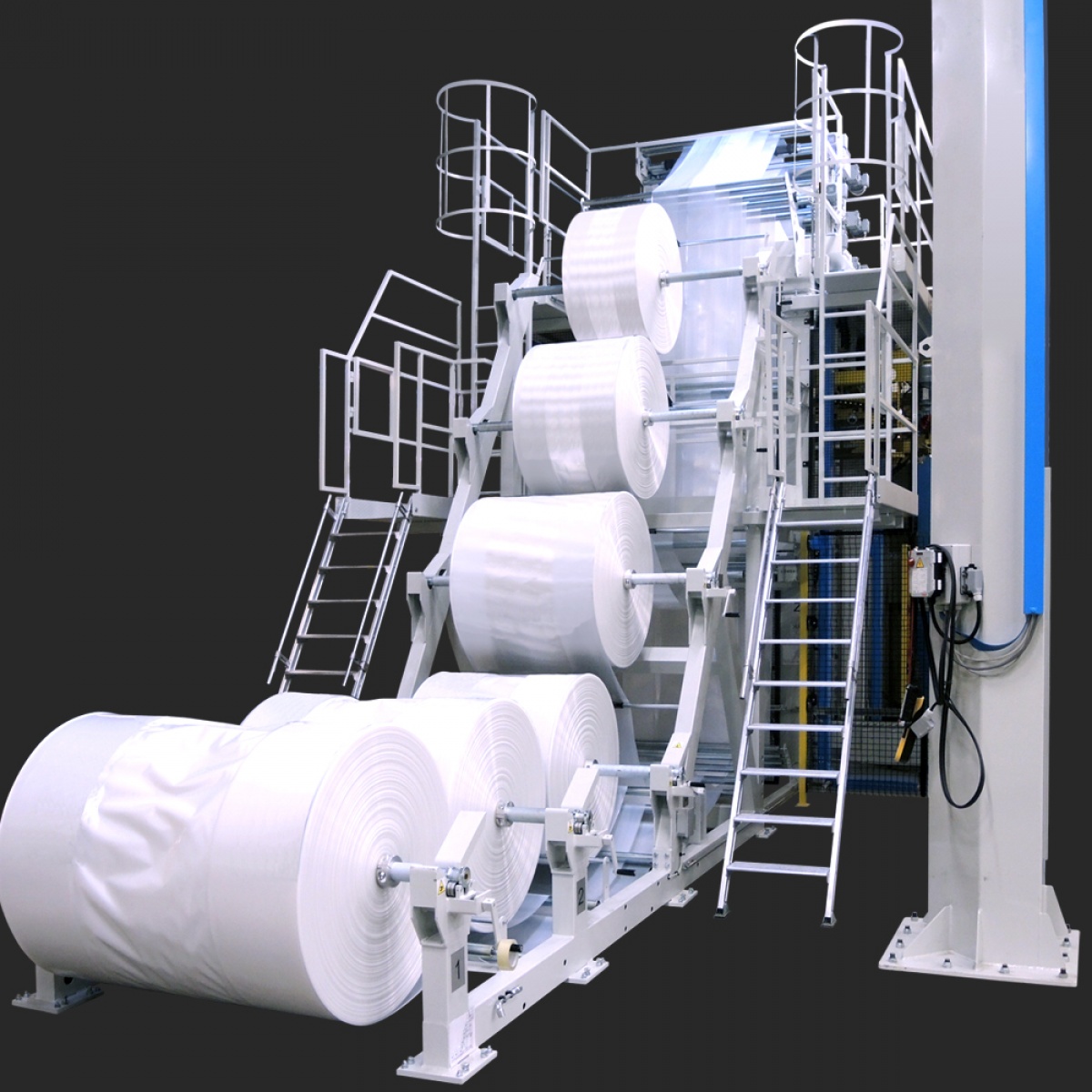

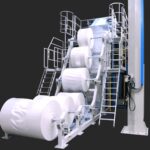

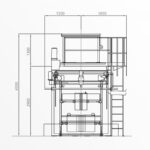

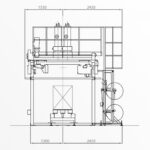

The machine can work in a maximum configuration with up to 3 separate stretch films of different sizes. The packing capacity averages 80 pallets per hour. However, the exact output is dependent on the pallet dimensions and the packing system setup.

Only the necessary amount of foil, nothing extra

The process of applying the film is mechanical, without the need for additional energy required to shrink the film. Therefore, this equipment is suitable for the packaging of any kind of goods, including flammable and explosive materials, with the exception of high temperature products. The equipment is suitable for installation in explosive environments and also environments with an increased risk of fire. Additionally, when compared to conventional stretch wrapping, this technology is significantly more economical on the amount of film consumed.

Predestined for packaging automation

Wrapping in film is fully automated with the Stretch Hooder FB1000. In addition to the standard installation of the machine, it is possible to design a complete packaging system, complete with conveyor line and other packaging systems, or to implement the machine into the customer’s existing conveyor lines.

Stretch Hooder FB1000 reliably packs

- bagged products in both paper and plastic bags,

- building elements, tiles, cladding,

- Drinks,

- white technique,

- Food,

- glass and ceramics,

- insulation materials,

- containers and shipping containers,

- Paper,

- Textiles.

… and finally, the benefits at a glance

- packing capacity 80 pallets per hour ,

- significant savings in packaging materials,

- 100% dustproof and 100% waterproof of the resulting package,

- suitable for all types of pallets.