Unique helper for packaging parcels in stretch film

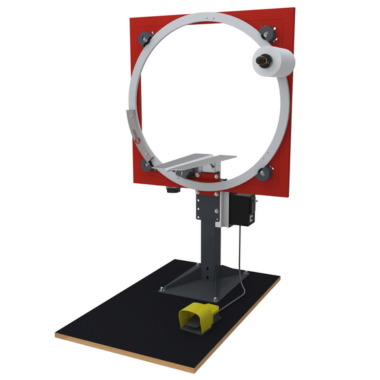

WRAPPING RING is a wrapping packaging machine for wrapping in black or clear stretch film, which ensures the anonymity of the wrapped goods and protects them from dust and moisture. With WRAPPING RING, shipments will be dispatched faster and more efficiently. Packing in stretch film becomes more economical and aesthetic with WRAPPING RING. Thanks to the motorised wrapping, the operator can wrap shipments with minimum effort.

WHY WRAPPING RING?

| Parameter | Value |

| Largest object size (diagonal) | 880 mm / 1250 mm |

| Maximum permissible package weight | up to 70 kg |

| Noise level during operation | below 70 dB |

| Power supply | 230 V, 50 Hz |

| Power consumption (motor version) | 0,37 kW |

WHO IS THE MACHINE INTENDED FOR

- e-shops

- logistics and shipping centers

- manufacturing companies

- tire sellers

- tire distributors

- construction and technical goods sellers

- bagged product manufacturers

- companies with regular packaging of 15+ shipments per day

WRAPPING RING is a purely Slovak product!

The model range of WRAPPING RING packaging machines is based on our own design of the entire construction and our own production of these machines. Thanks to our extensive experience in the field of professional packaging technology, our design office has been able to create the perfect maintenance-free machine with which you will be reliably packing your shipments for dispatch for many years to come.

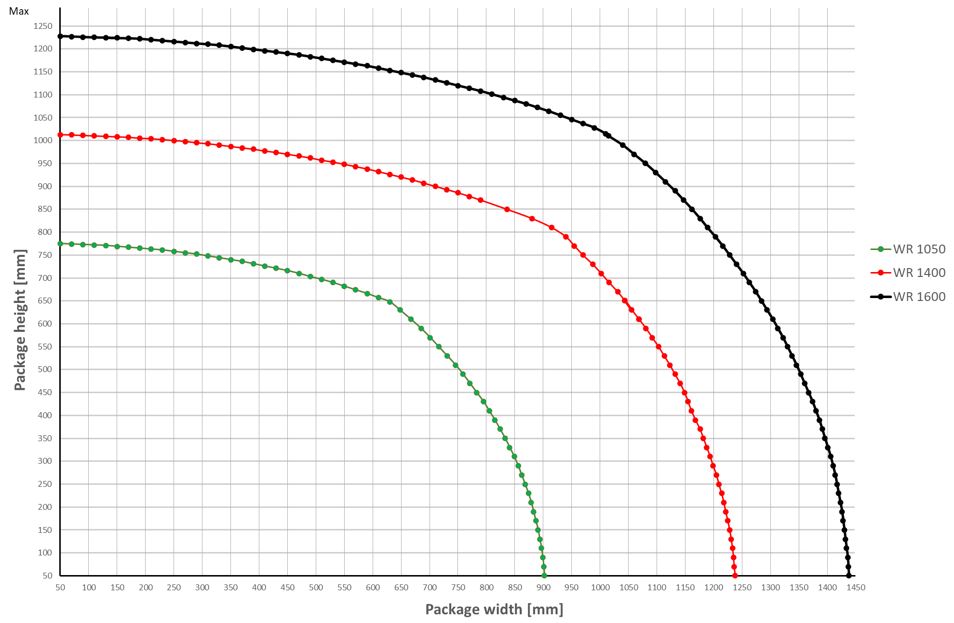

WRAPPING RING SERIES MODEL OVERVIEW

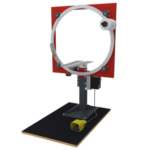

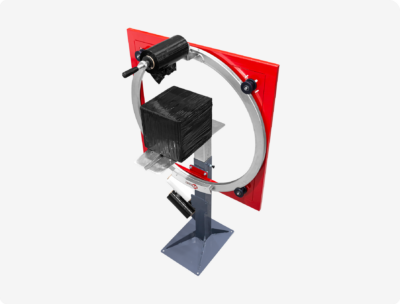

Hand Wrap (Model H)

For smaller and medium-sized operations with lower wrapping intensity.

- WR1050H

- WR1400H

Manual Wrapping Ring Machine

| Parameter | Technical specification – model H |

| Device type | Circular packaging machine – version H |

| Product range | WR 1050 H / WR 1400 H |

| Power supply | 1+N+PE, TN-S, 230 V AC / 50 Hz |

| Control voltage | 24 V DC (PELV) |

| Rated power consumption | 0,37 kW |

| Input fuse | 16 A |

| Minimum cross-section of the supply cable | 3 × 1,5 mm² |

| Protection | IP 54 |

| Ring speed | WR 1050H: 32 ot./min (20 ot./min*)

WR 1400H: 22 ot./min (14 ot./min*) |

| Inner diameter of the ring | WR 1050H: 930 mm (480 mm**)

WR 1400H: 1 280 mm (800 mm**) |

| Approximate time wrapping time | approx. 20 – 60 seconds (depending on package size) |

| Noise | < 70 dB(A) |

| Operating temperature | +15 °C až +45 °C |

| Maximum relative humidity | up to 70 % |

| Dimensions (W × D × H) | WR 1050 H: max. 1050 × 820 × 1780 mm

WR 1400 H: max. 1400 × 820 × 1955 mm |

| Weight | WR 1050 H: max. 90 kg

WR 1400 H: max. 105 kg |

* When using a 500 mm wide foil dispenser

** When using a bubble wrap dispenser

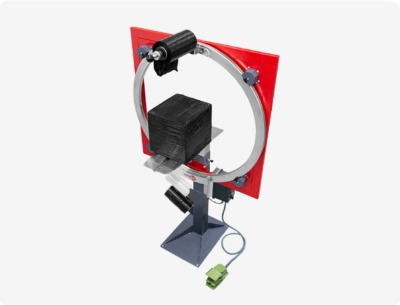

Motorized Packaging (Model M)

For medium and larger operations with higher volume shipments.

- WR1050H

- WR1400H

- WR1600M

- WR1800M

Motorized Wrapping Ring M packaging machine

| Parameter | Technical specification – model M |

| Device type | Circular packaging machine – version M |

| Product range | WR 1050 M / WR 1400 M / WR 1600 M |

| Power supply | 1+N+PE, TN-S, 230 V AC / 50 Hz |

| Control voltage | 24 V DC (PELV) |

| Rated power consumption | 0,37 kW |

| Input fuse | 16 A |

| Minimum cross-section of the supply cable | 3 × 1,5 mm² |

| Protection | IP 54 |

| Ring speed | WR 1050 M: 32 ot./min (20 ot./min*)

WR 1400 M: 22 ot./min (14 ot./min*) WR 1600 M: 21 ot./min (10 ot./min*) |

| Inner diameter of the ring | WR 1050 M: 930 mm (480 mm**)

WR 1400 M: 1 280 mm (800 mm**) WR 1600 M: 1 480 mm (1 000 mm**) |

| Approximate wrapping time | approx. 20 – 60 seconds (depending on package size) |

| Noise | < 70 dB(A) |

| Operating temperature | +15 °C až +45 °C |

| Maximum relative humidity | up to 70 % |

| Dimensions (W × D × H) | WR 1050 M: max. 1050 × 730 × 1780 mm

WR 1400 M: max. 1400 × 730 × 1955 mm WR 1600 M: max. 1600 × 1200 × 2015 mm |

| Weight | WR 1050 M: max. 105 kg

WR 1400 M: max. 120 kg WR 1600 M: max. 145 kg |

* When using a 500 mm wide foil dispenser

** When using a bubble wrap dispenser

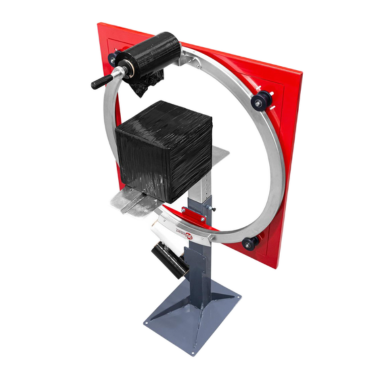

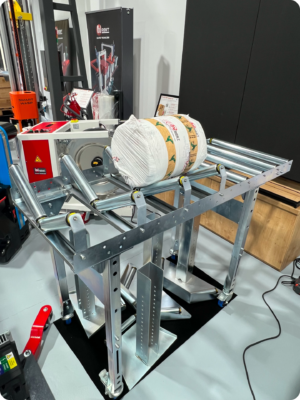

Motorized Tire and Round Object Wrapping (Model T)

Specialized solution for tire shops, manufacturers and distributors of round products.

- WR1050T

- WR1400T

Motorized wrapping machine for wrapping tires and round objects Wrapping Ring

| Parameter | Technical specification – model T |

| Device type | Round packaging machine – version T |

| Product range | WR 1050 T / WR 1400 T |

| Power supply | 1+N+PE, TN-S, 230 V AC / 50 Hz |

| Control voltage | 24 V DC (PELV) |

| Rated power consumption | 0,37 kW |

| Input fuse | 16 A |

| Minimum cross-section of the supply cable | 3 × 1,5 mm² |

| Protection | IP 54 |

| Ring speed | WR 1050 T: 32 ot./min (20 ot./min*)

WR 1400 T: 22 ot./min (14 ot./min*) |

| Inner diameter of the ring | WR 1050 T: 930 mm (480 mm**)

WR 1400 T: 1 280 mm (800 mm**) |

| Approximate time wrapping time | approx. 20 – 60 seconds (depending on package size) |

| Noise | < 70 dB(A) |

| Operating temperature | +15 °C až +45 °C |

| Maximum relative humidity | up to 70 % |

| Dimensions (W × D × H) | WR 1050 T: max. 1050 × 921 × 1780 mm

WR 1400 T: max. 1400 × 921 × 1955 mm |

| Weight | WR 1050 T: max. 120 kg

WR 1400 T: max. 135 kg |

* When using a 500 mm wide foil dispenser

** When using a bubble wrap dispenser

Savings model for 20 packages per day

| Indicator | Manual Packing | Packaging machine WR | Savings |

| Average time for 1 package | 4 min | 40 sec | – 3 min 20 s |

| Daily packaging time (20 pcs) | 80 min | 13 min | 67 min per day |

| Monthly time (20 days) | 26,7 hrs | 4,3 hrs | 22,4 hrs / month |

| Monthly labor costs | 267 € | 43 € | 224 € savings / month |

| Annual labor savings | – | – | 2 688 € / year |

Savings model for 40 packages per day

| Indicator | Manual Packing | Packaging machine WR | Savings |

| Daily packaging time | 160 min | 27 min | 133 per day |

| Monthly time (20 days) | 53 hrs | 9 hrs | 44 hrs / month |

| Monthly labor costs | 530 € | 90 € | 440 € savings / month |

| Annual labor savings | – | – | 5 280 € / year |

Other economic benefits

| Area | Benefit |

| Foil consumption | more even tension = approx. 10 – 20% material savings |

| Goods damage | reduction in complaints (stronger and uniform packaging) |

| Employee productivity | freeing up capacity for other work |

| Ergonomics | less physical strain and PN |

| Return on investment | for medium operation often 6 – 18 months |

MAIN ADVANTAGES

- Easy and safe handling

- Motorised or manual wrapping

- Height adjustable frame

- Height adjustable work table

- Infinitely variable film tension control

- Quick film change

- Durable surface finish

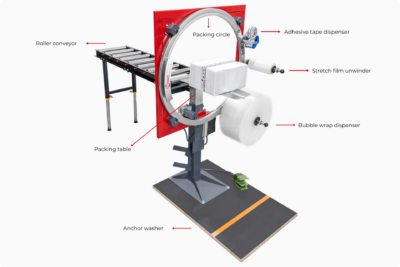

ACCESSORIES

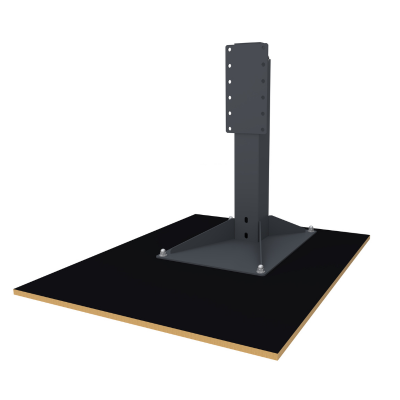

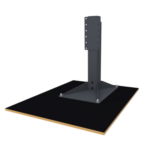

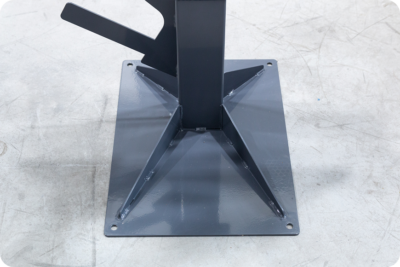

Anchoring the machine

Standard anchoring to the floor

The most stable solution – the machine is firmly anchored directly to the floor, which ensures maximum stability during operation.

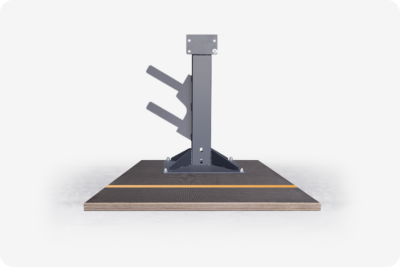

Mobile base with wheels

The machine can be mounted on a mobile base equipped with wheels with brakes. This solution allows easy movement of the device within the operation according to current needs.

Waterproof stabilizing base (1200 × 800 mm)

If anchoring to the floor is not possible or desired, the machine can be placed on a special stabilizing base with dimensions of 1200 × 800 mm.

The base ensures high stability without the need to intervene in the floor and at the same time protects the surface under the device. It is also suitable for areas with higher humidity.

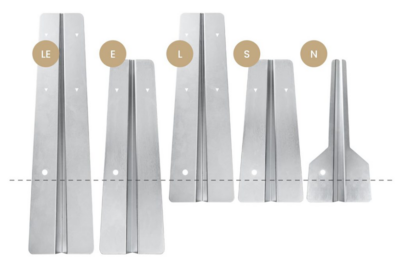

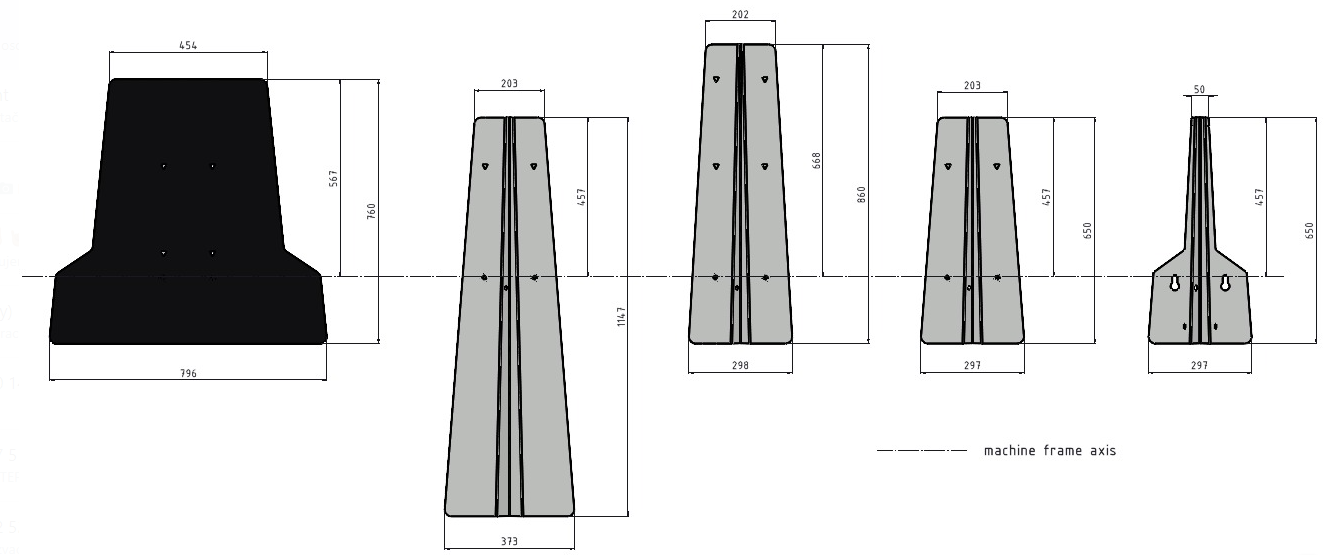

Packing table

Manual and motorized versions allow the standard S-type packing table to be replaced with a variant that better matches the shape, dimensions and type of the packed shipment.

This allows the machine to be adapted to specific operational requirements.

N – Narrow

Suitable for packing smaller shipments with side lengths from 100 mm. Ideal solution for compact packages and smaller goods.

S – Standard (TOP)

Universal version designed for regular packing of shipments with side lengths from 200 mm. The most commonly used configuration.

L – Long

Designed for packing larger shipments, especially when using 500 mm wide stretch film.

E – Extended

A specialized table for packing bagged products such as feed, fertilizers and other bulk goods.

LE – Double-sided extended

Suitable for packaging long bagged shipments, allows for efficient use of 500 mm wide stretch film and provides increased stability during packaging.

For tires and round objects

Special design designed for packaging tires and other round or rotating objects that require stable placement during the packaging process.

Stretch film unwinder

Stretch film is the basis of strong and compact packaging. The correctly selected unwinder width affects the packaging speed, material consumption and the resulting stability of the shipment.

The packaging machine is standardly equipped with a 250 mm foil unwinder, which can be replaced with a 125 mm, 500 mm or coreless foil unwinder depending on the type of packaged goods.

125 mm – precise and economical packaging

- suitable for smaller packages

- lower material consumption

- ideal for light shipments

250 mm – universal solution (recommended)

- most frequently used width

- suitable for most shipments

- optimal ratio of speed and foil consumption

500 mm – speed and maximum stability

- suitable for large or heavy packages

- fewer turns = faster packaging

- higher fixation strength

Unwinder for coreless foil

| Parameter | 125 mm | 250 mm | 500 mm* |

| Foil thickness | 10 – 23 μm | 10 – 23 μm | 10 – 17 μm |

| Maximum roll weight | 3,0 kg | 2,5 kg | 2,5 kg |

| Inner core diameter | 50 mm | 50 mm | 50 mm |

| Core wall thickness | 7 – 10 mm | 7 – 10 mm | 7 – 10 mm |

| Core length | +8 až +10 mm compared to foil width | +8 až +10 mm compared to foil width | +8 až +10 mm compared to foil width |

| Available colors | Clear / Black / White | Clear / Black / White | Clear / Black / White |

*To use 500 mm wide film, it is necessary to use the L (Long) wrapping table.

*When using the 500 mm wide stretch film unwinder, it is not possible to install other unwinders at the same time (125/250 mm stretch film, adhesive tape unwinder or bubble wrap unwinder).

*500 mm wide film unwinders cannot be used with the following models:

- WR 1050 T

- WR 1400 T

- WR 1050 M / WR 1400 M with installed output roller conveyor

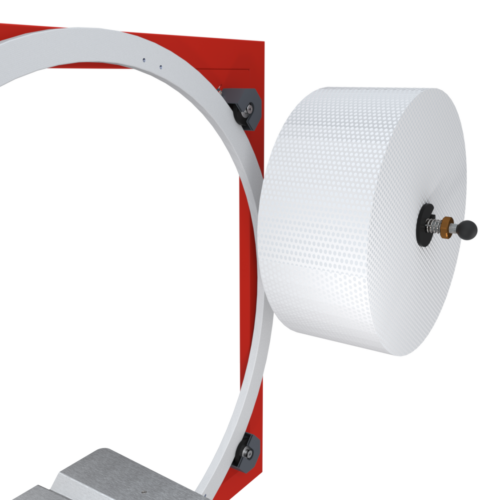

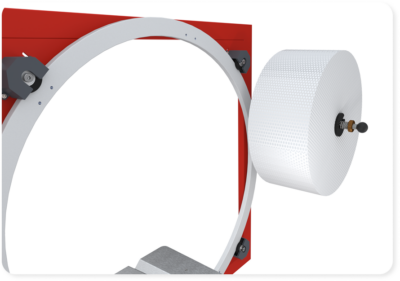

Bubble wrap dispenser

The bubble wrap dispenser expands the packaging options with a cushioning protective layer, which significantly increases the safety of the shipment during handling and transport.

It is intended as an optional accessory and allows you to apply the protective layer directly during packaging without additional handling.

Available widths:

- 250 mm – suitable for smaller and medium-sized shipments

- 500 mm – ideal for larger or heavier packages

| Foil width | 250 / 500 * mm | |

| Maximum roll diameter | 500 mm | |

| Foil thickness | 40 / 60 / 80 / 100 μm | |

| Core | inner Ø | 76 |

| length | longer min. + 2 mm / max. + 10 mm than foil width | |

* For a foil width of 500 mm, a table version L is required

Advertising adhesive tape dispenser

The packaging machine can be supplemented with an adhesive tape dispenser, which allows the shipment to be tightly closed and secured immediately after packaging.

Available versions:

- 50 mm

- 75 mm

Thanks to integration directly on the machine, the shipment is fixed smoothly, without the need for an additional work step.

| Tape width | 50 / 75 mm |

| Core | inner diameter Ø 76 mm |

| Roll | max. 132 m |

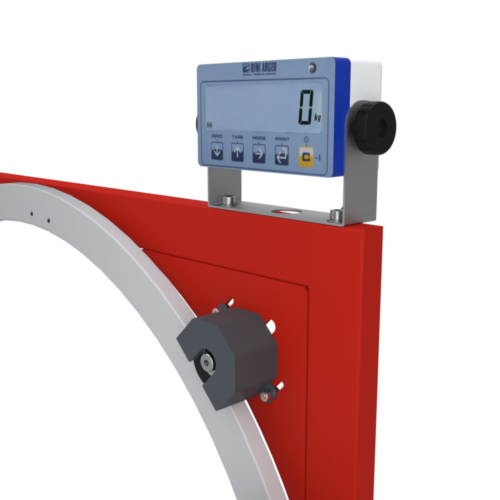

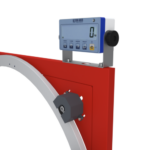

Weighing system

The integrated weighing system enables accurate weighing of the shipment directly during the packaging process. This eliminates the need to move the package to a separate scale and significantly speeds up the entire process.

Weighing is performed automatically without interrupting the work cycle, which increases the efficiency and accuracy of the shipment. The obtained weight data can be displayed on the display and sent to external systems – for example, to ERP, warehouse system (WMS) or directly to the carrier’s transportation software.

Integration enables automatic data transfer, minimizes errors when rewriting data and ensures correct billing of transportation according to the real weight of the shipment.

Conveyors

The packaging machine can be expanded with an input and output roller conveyor or a packaging machine, which significantly simplifies the handling of shipments and speeds up the entire shipping process.

Conveyors enable smooth feeding of packages into the packaging zone and their convenient removal after packaging without unnecessary lifting or carrying.

Standard conveyor designs

- length 1,000 mm

- length 1,500 mm

- length 2,000 mm

On request, the conveyor can also be manufactured in an individual length according to the layout of the operation.

ADVANCED CONFIGURATION OPTIONS

Motorized conveyors

Automate the movement of shipments into and out of the machine without the need for manual shifting. The ideal solution for higher packaging capacity and smooth logistics.

Motorized conveyors with integrated weighing system

Enable automatic weighing of the shipment during transfer. The scale can be connected to ERP, WMS or transportation system, eliminating manual data entry and reducing errors.

Custom packing table

In addition to standard types, it is possible to manufacture a packing table adapted to a specific type of shipment, package dimensions or specific operational requirements.

WR V Conveyor

The WR V Conveyor is designed for easy and safe packaging of long circular objects when using WR machines.

It ensures a stable and desired position of the packaged object throughout the process, thereby:

✔ increasing packaging efficiency

✔ reducing physical demands on the operator

✔ improving the quality of film tension

✔ helping to save packaging material

The continuous adjustment of the conveyor height allows for optimal adaptation to the packaging machine and achieving high-quality and uniform film tension.

WR V The conveyor is manufactured by W rent, which allows for its wide personalization and technical adaptation according to the individual needs of the customer.

Safety cover

The WR cover is made of clear, solid polycarbonate sheet with UV stabilization, which is characterized by high impact resistance and a wide range of applicability in temperatures from -40 °C to +135 °C.

The material is:

- extremely impact-resistant

- up to 50% lighter than glass

- fully transparent for visual process control

- UV stabilized for long-term durability

Thanks to these properties, the WR cover not only fulfills a safety function, but also allows convenient and safe monitoring of the package without limiting visibility.

The robust construction and high-quality materials ensure long-term durability even in demanding operating conditions.

MAXIMUM SHIPMENT PROTECTION DURING TRANSPORT

By combining bubble wrap, stretch wrap and adhesive tape, you create a multi-layered protection that significantly reduces the risk of damage to goods during handling and transport. Each layer fulfills its important function.

Shock absorption and mechanical protection

By using bubble wrap, you create a protective layer that absorbs shock, pressure and accidental falls. The contents of the shipment are thus better protected from damage during handling in warehouses and during transport.

Protection against dust and moisture

Stretch wrap ensures a tight wrapping of the shipment and creates a protective barrier against dust, moisture and pollution. The shipment remains clean and compact throughout the distribution route.

Secure closure and protection against unauthorized manipulation

By using standard, printed or security adhesive tape, you minimize the risk of unwanted opening of the shipment. This increases the credibility of the delivery and the protection of the contents.

FILES FOR DOWNLOAD

How much could Wrapping Ring save your business?

Every business is different.

We will be happy to prepare a savings model for you free of charge, based on the number of packages, type of goods and workload.

Contact us for an individual ROI calculation.