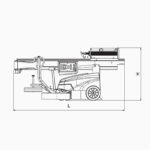

SIAT BeeWrap mobile wrapping machine

Be mobile when packing pallets!

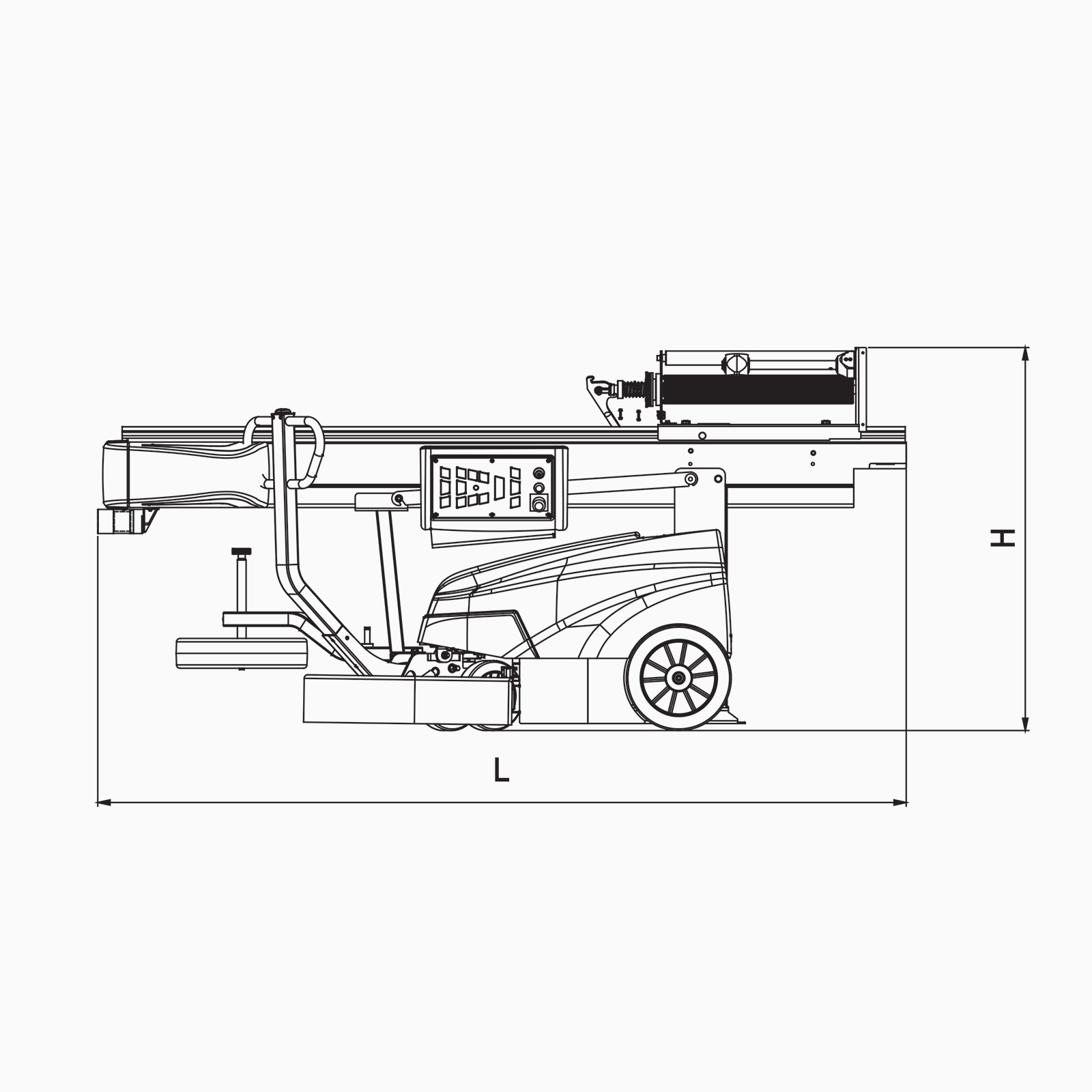

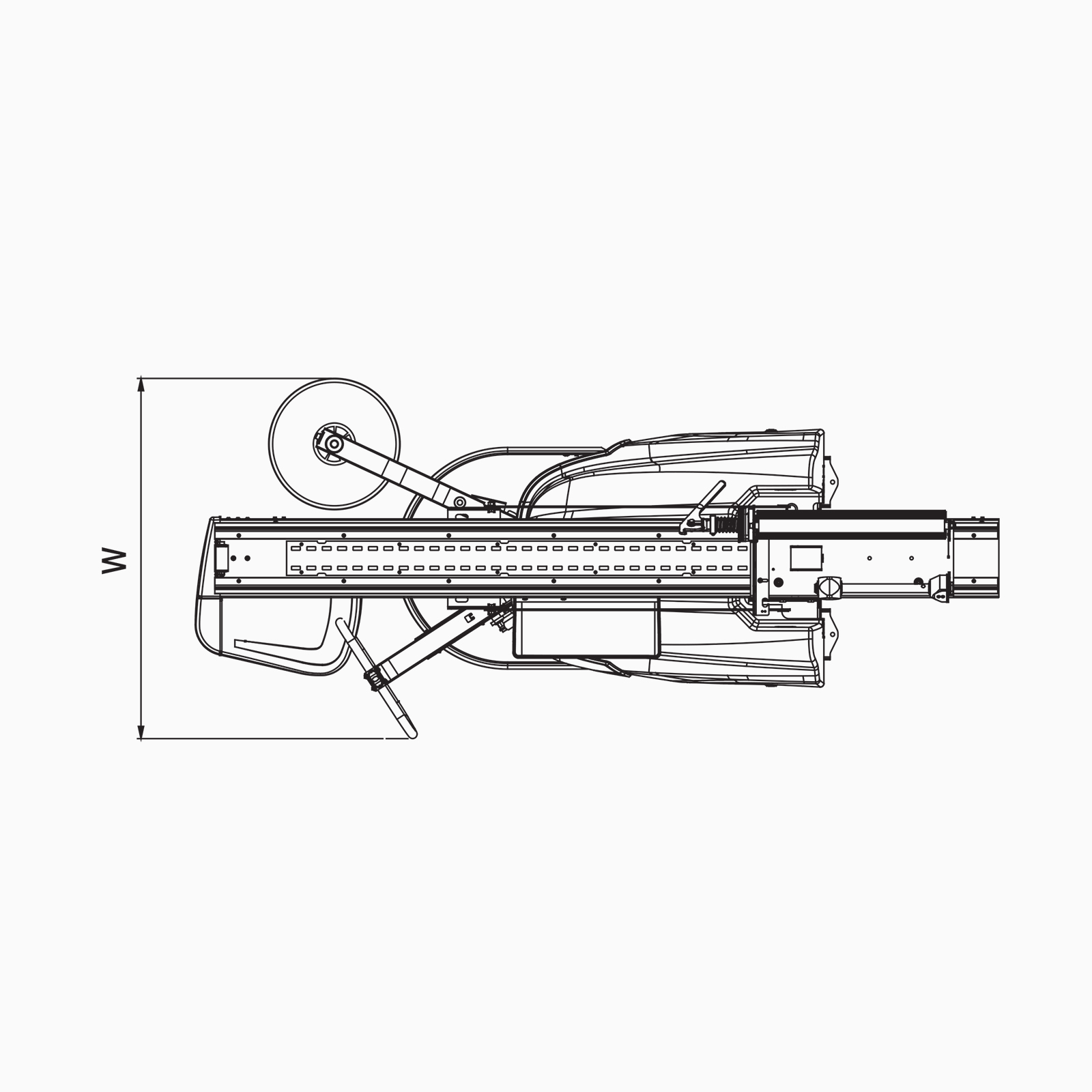

SIAT BeeWrap is a mobile wrapping machine for wrapping pallet shipments of any shape, size or weight with stretch film. With the motorised travel, the wrapping of each pallet is very fast and the machine can be moved quickly between wrapped pallets without much effort from the operator. The machine is particularly suitable for workplaces with limited handling space.

SIAT BeeWrap stands out for its simple operation

The control panel can be used to set the packing method and parameters of the entire packing process, or to program up to 10 different packing programs between which the machine operator can quickly switch. The integrated pre-stretch system allows for significant savings in film consumption. SIAT BeeWrap includes a number of integrated safety features (light and sound alarm, photocell, impact zone), which ensure that the operator’s safety is not compromised and also eliminate the possibility of damage to the packaged consignment.

Key features

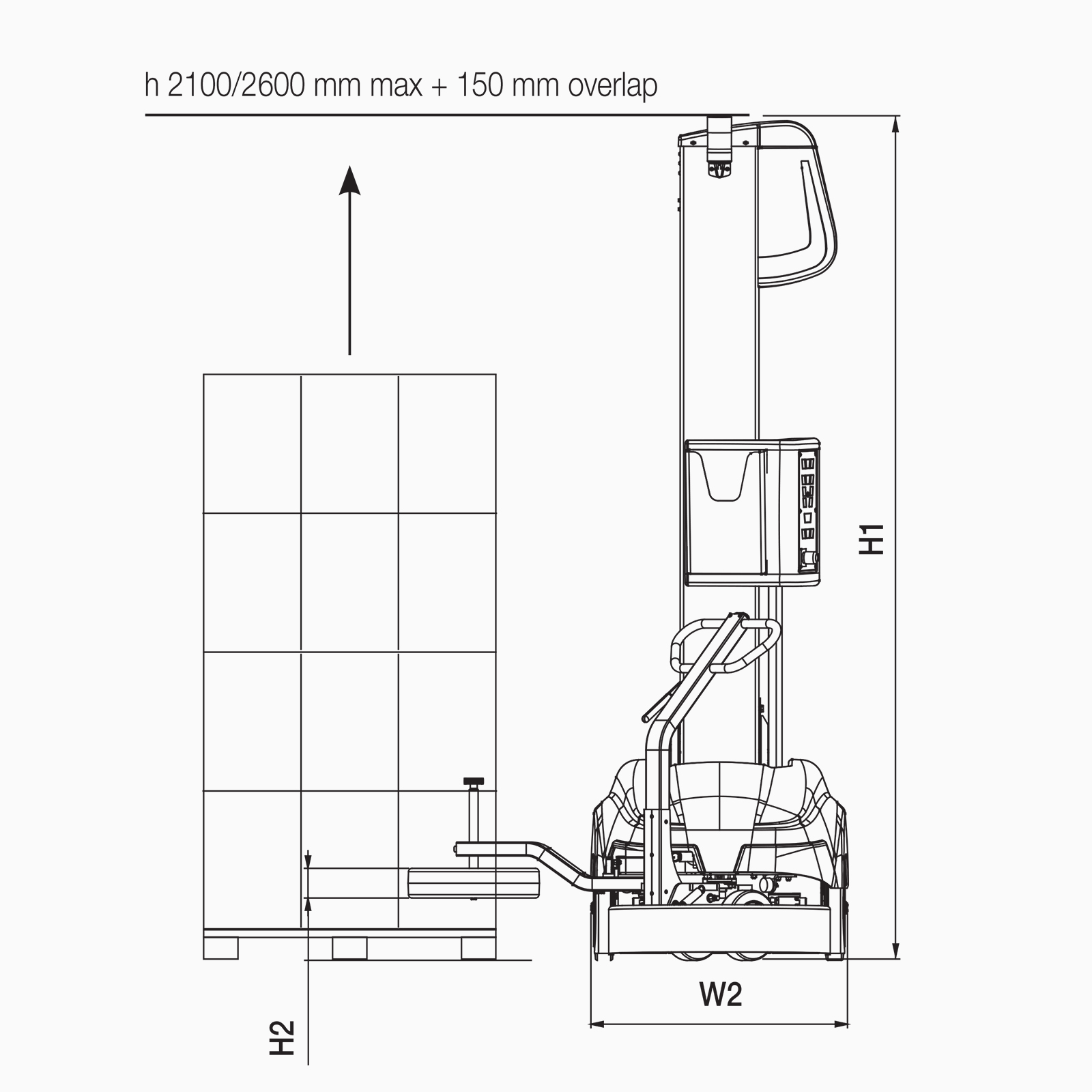

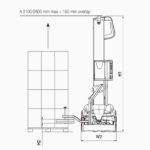

- For pallets with max. height 2100 / 2600 mm.

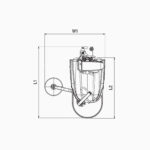

- Packing with stretch film 500 x 250 mm / 76 mm / 17/23 μm (width X outer diameter / cavity diameter / film thickness).

- Ideal packaging machine for oversized round-shaped shipments.

- Required working / handling space 1150 mm around the packed item.

- Safety sensors on the machine bumper.

- Light and sound signalling of machine operation.

- Power supply by lead acid battery 2x 12V, built-in charger.

- Easy handling and operation of the machine by means of a handle and motorised drive.

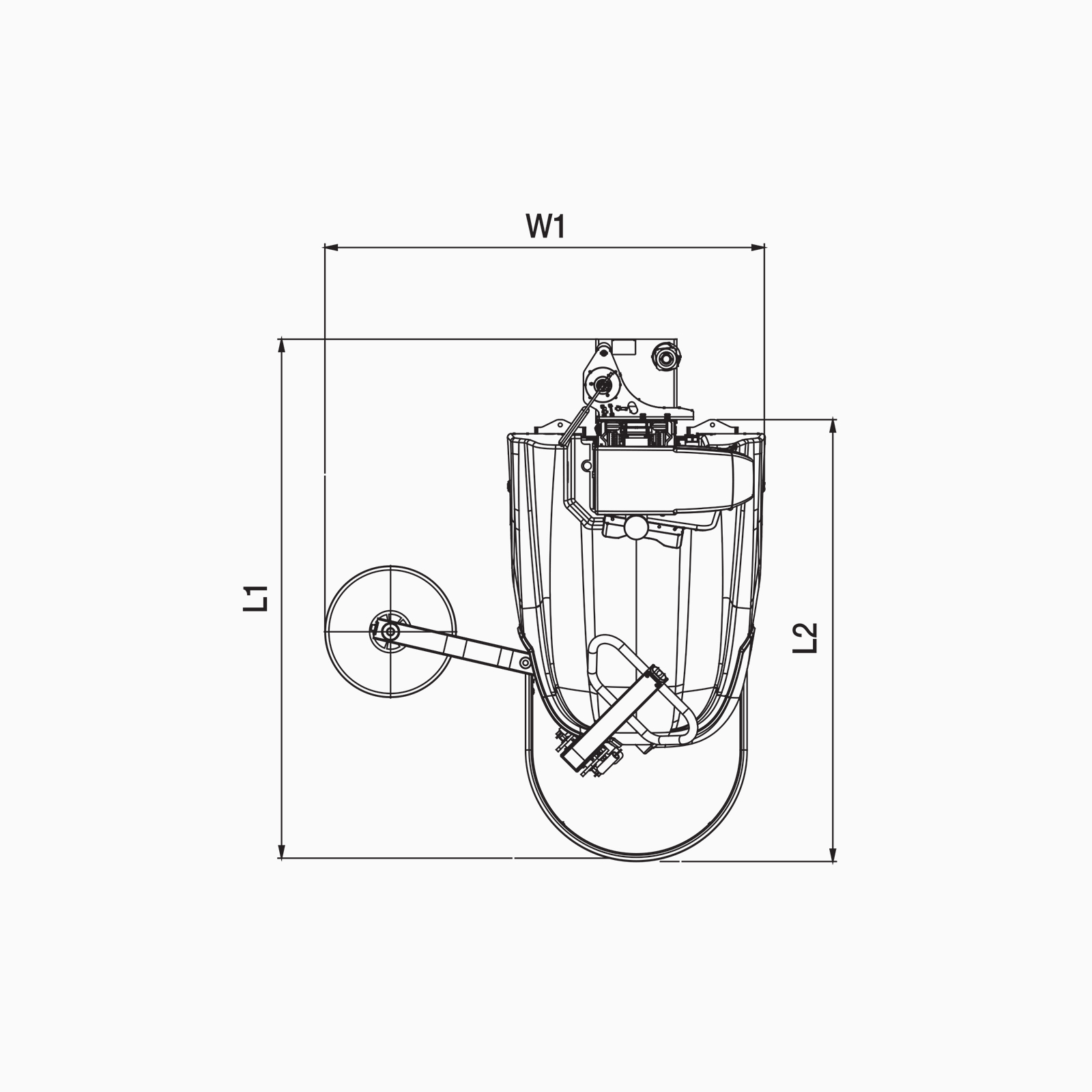

- Adjustable height of the tracking wheel of the packed object.

- Access to the foil trolley at the rear of the machine.

- Folding column for easier handling and repositioning of the machine.

- Control panel with extended functionality, up to 10 programmable packaging programs.

- Film trolley with brake (mechanical / electromagnetic) or with motorized stretch film pre-stretching (pre-stretch 100-240% – Saving stretch film and better stability of the wrapped shipment).

- Photocell for pallet height sensing.

- Working cycle per charge up to 300 pallets.

Optional machine configuration

TIP: We recommend a configuration with a trolley with motorized stretch LP film stretching to 100-240% of its original stretch, which ensures perfect stabilization of the packed shipment and significantly reduces the consumption of stretch film during packing!

Extension elements

- Gel accumulator.

- Photocell for detecting black film or colored objects during packaging.

- Remote control.

- Foil cutter (only for LP foil trolley).

- Double tracking wheel of the packed object.

(*) packing parameters – column height 2100 mm, lead accumulators, pallet dimensions 800 x 1200 x 1500 mm (W x D x H), top-down packing, 2x top and 2x bottom overwrapping with foil, foil tension 10daN. (**) foil tension 6 daN. (***) bulky consignments can have a circumference of 26 m for packing in standard machine configuration.