The S 55DC HS and S 85DC HS tunnel has been enhanced with several new technical details useful to meet all packaging needs and can work with several shrink films. The S 55 DC HS tunnel has been designed for fast packaging of small products with optimal technical and aesthetic results. With double shrink chamber, double shrink adjustment, good thermal insulation, high speed conveyor, optimal airflow control, this machine is a very good and efficient packaging solution.

Options

- Variable speed fan

- Free roller conveyor step 46 mm length 1000 mm

- Protect Output Roller Conveyor Pitch 46 mm Length 1000 mm

Features

- Double chamber shrink tunnel

- FLXMOD® control system equipped with: Alphanumeric LCD control panel equipped with PC board

- Modular power section separated from control

- Panel and equipped with inverter and remote control switches

- This system allows easy and precise control of all machine operations, such as:

– tunnel conveyor speed setting

– tunnel shrink temperature setting

– possibility of planning up to 10 different working cycles - Tunnel conveyor with swivel or fixed rollers coated with silicone

- Cooling system

- Tunnel air flow adjustable by flaps

- Reduced energy consumption

- Compliance with CE regulations

Benefits

- High productivity: the S 85 DC HS tunnel enables fast and efficient shrink film shrink, increasing production capacity and packaging efficiency.

- Consistent shrinkage: the machine ensures uniform shrinkage of the film, which guarantees high quality and aesthetic appearance of the packaged products.

- Adjustable Parameters: Allows precise adjustment of temperature, belt speed and air flow, providing flexibility when working with different types and sizes of products.

- Energy efficiency: modern tunnel technologies and design features reduce energy consumption, which contributes to lower operating costs and reduces the environmental impact.

- Ease of use: the intuitive control panel and user-friendly interface make it easy to operate and set up the machine, minimising the need for extensive training for operators.

- Robust construction: the tunnel is made of high quality materials and with a solid construction, which guarantees a long service life and reliability even with intensive use.

- Minimal maintenance: The equipment is designed for low maintenance, reducing downtime and service costs.

- Compact design: The compact size of the tunnel allows it to be easily integrated into a variety of production lines and workspaces, which is advantageous for smaller operations or confined spaces.

- Compatibility with various films: The tunnel is compatible with various types of shrink films, including polyolefin (POF), PVC and polyethylene (PE), increasing its versatility.

- Safety features: Modern safety features ensure safe operation and protect operating personnel.

- Even heat distribution: Advanced technological solutions ensure even heat distribution inside the tunnel, minimising the risk of overheating or damage to the foil.

- Customisability: the equipment can be tailored to customer-specific requirements, allowing optimal use in a variety of industries.

- Waste reduction: efficient use of shrink film helps to minimize waste, which is economically beneficial and environmentally friendly.

- Integrated cooling: some models can be equipped with an integrated cooling system that speeds up the cooling process of products after shrinking, allowing for faster handling and processing.

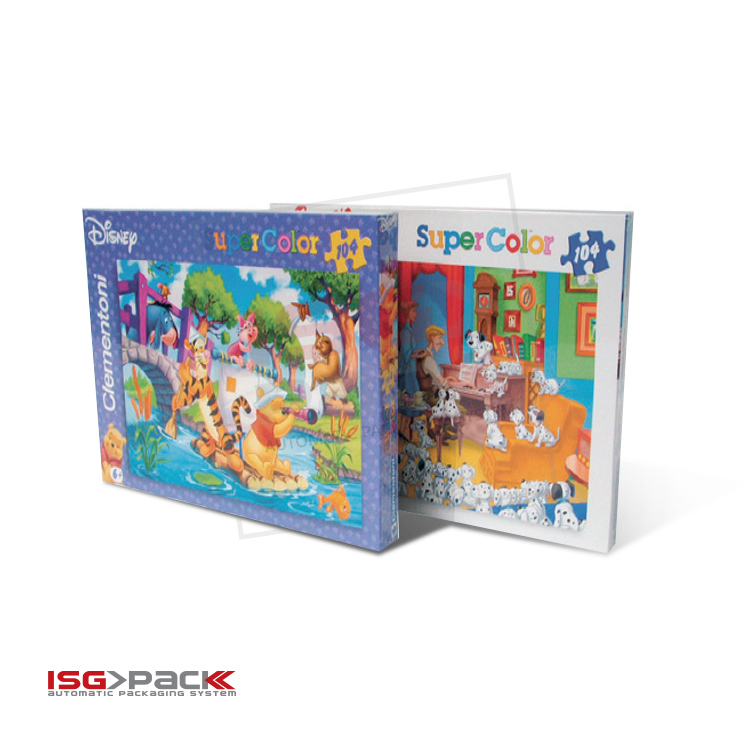

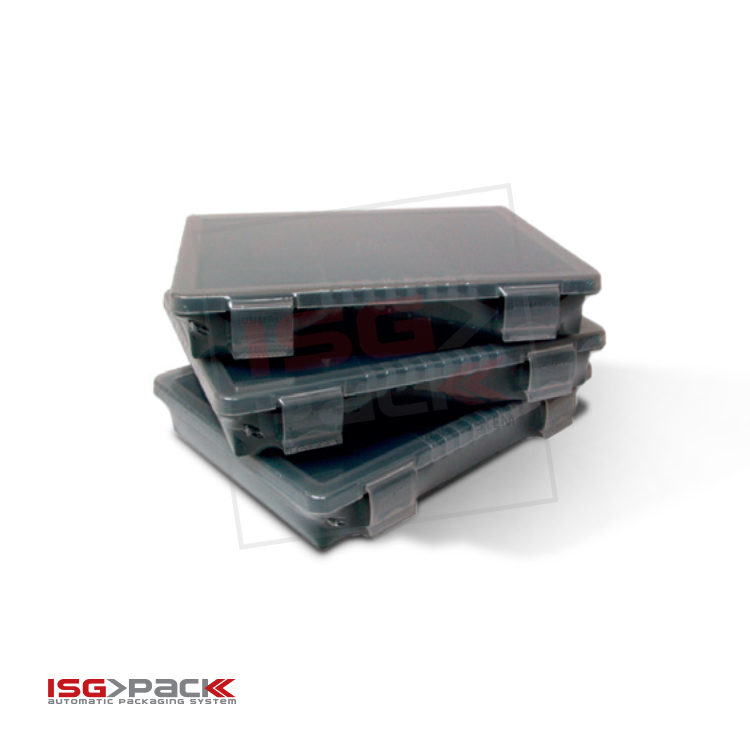

- Versatility of use: the S 85 DC HS tunnel is suitable for packaging a variety of products, including food, industrial goods, electronics and consumer goods, making it a versatile solution for a variety of industries.

- Advanced Design: The equipment includes advanced features such as precise airflow and temperature control to improve performance and customization of the packaging process.