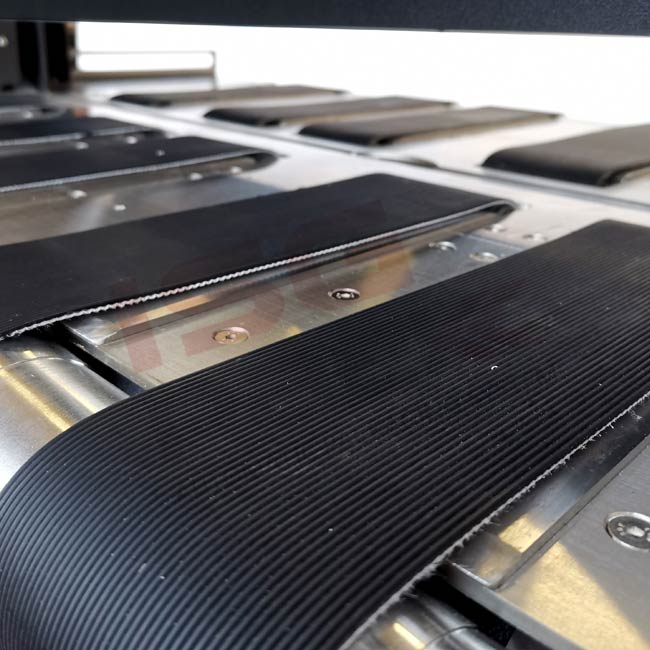

Automatic strapping machine with motorised belts on the working surface

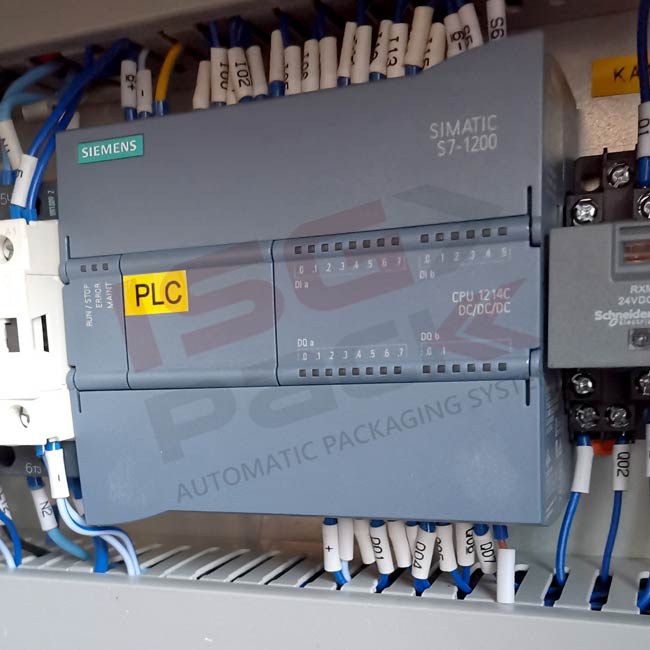

The fully automatic strapping machine of the Easy Strap B series is compact, reliable, robust and easy to use. It can be inserted into a fully automatic production line, ensuring a medium-high working capacity. The work table is equipped with a motorized belt conveyor and the machine can automatically work with 1-2 or more belts via a photocell system, adjustable via a control panel rotatable 180° to work on both sides of the machine. It operates with DC motors that control every function of the machine. More than 30% of the mechanical components have been eliminated compared to a traditional tape machine. Also available with pneumatic top press.

Features and parameters of the strapping machine

Technical features

- Work table with motorised conveyor belt

- Stainless steel safety handle

- Magnetic safety switches

- Automatic tape feeding

- Single, double or multiple tapes

- Setting the tape using the control panel

- Transit mode without product banding

- Belt speed adjustable by potentiometer

- Acoustic and 3-colour light signal

- Emergency stop button

- Loop extension

- 180° rotatable analogue control panel

- Tape cutting equipment

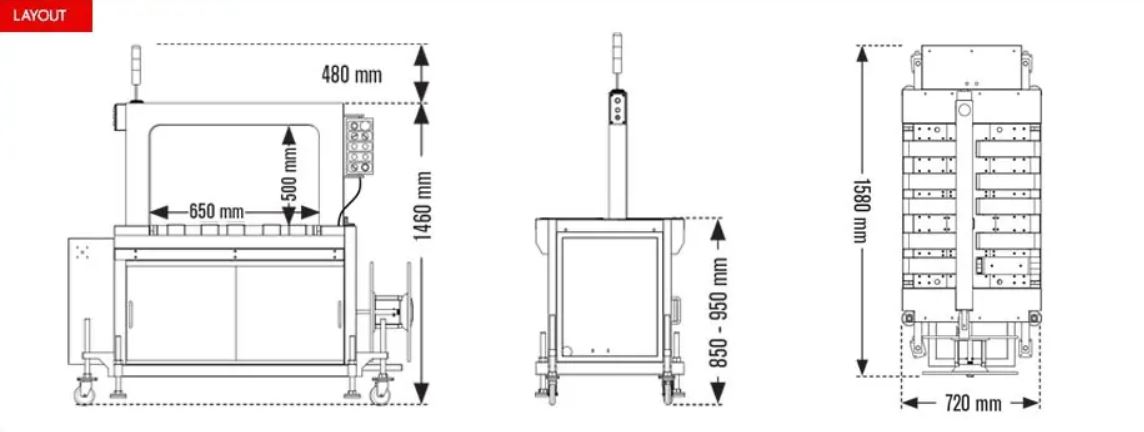

- Adjustable workbench height

- Automatic tape ejection at the end of the tape spool

- Re-feed tape system

- Possibility to use different tape sizes

- Different sizes of arches are available

- Tape tension up to 45 kg adjustable by potentiometer

Product Features

- Max. Product dimensions.

- Product weight: 30 kg.

Features of the webbing scrolling

- Inner diameter: 200 mm

- Outside diameter: 400 – 450 mm.

- Tape width: 9 – 12 mm

- Tape thickness: 0.45 – 0.65 mm.

- Tape type: PP (polypropylene)