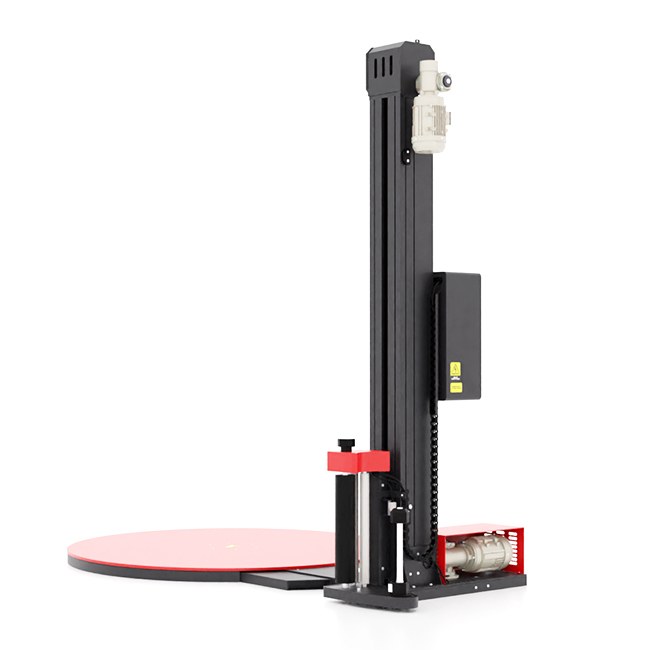

Semi-automatic wrapping machine E-Wrap 1000 A with mechanical brake

The E-Wrap 1000A is the ISG PACK machine with the best price/quality ratio on the market. It is a semi-automatic wrapping machine suitable for all standard applications thanks to its 6 working programs. This machine has an integrated PC board which gives alarm and error signals during the wrapping cycles (on a 7,2” touch screen). In addition, there is a light system at the top of the column that informs the operator if the machine is working, in the basic position or in error/ emergency state.

Functions of stretch wrapping

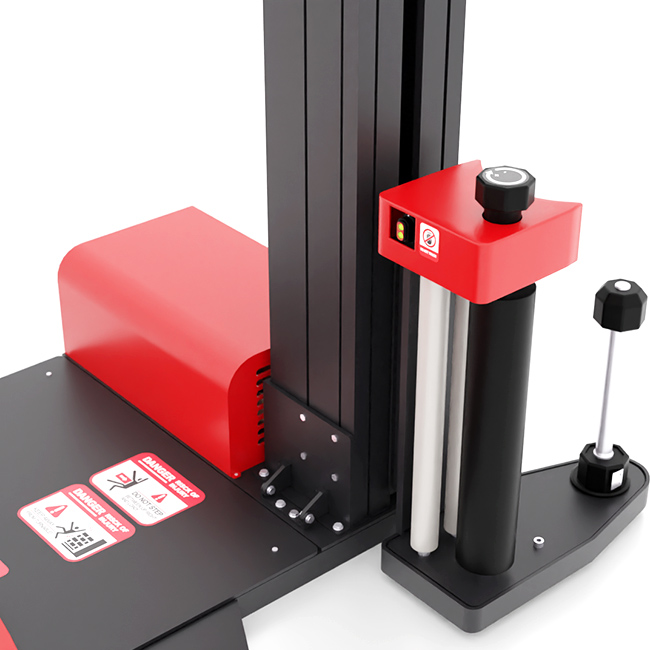

The E-Wrap 1000A turntable has a diameter of 1500 mm and a maximum load capacity of 1500 kg. The turntable rotation is activated by a drive chain and controlled by a magnetic sensor that verifies the number of rotations, deceleration times and the home position of the table at the end of the working cycle. The standard column allows wrapping pallets up to 2200 mm high. The trolley is equipped with a mechanical brake and a photoelectric sensor for product detection.

Touch screen functions

From the touch screen homepage, many packaging parameters can be programmed in a very simple and intuitive way: the number of wrapping rolls at the top and bottom of the pallet, the number of cycles at the top and bottom of the trolley, the speed of the turntable, the speed of the trolley, the setting of the photocell delay for the stretch film overlay. In addition, there are other integrated functions such as wrapping cycle in manual mode, admin system settings, machine job statistics logging and technical area to monitor input and output signals, historical alarm database, maintenance operations performed on the wrapping machine.

Layout

Technical details

- Machine construction in steel and aluminium

- Aluminium column folding on the machine base for quick installation

- Double drive chain activated trolley

- Machine equipped with integrated PC board controlled by 7,2” touch screen

- Emergency stop device in accordance with CE regulations

- 3-colour light alarms at the top of the pole

- Troubleshoot errors using the touch screen

- Start, stop and reset activated by touch screen or button

- Stretch film tensioning by trolley with mechanical brake

- Emergency stop in accordance with CE regulations

- Machine reset button in operation in accordance with CE regulations

- Soft start and indexed turntable stop

- Statistics, times and number of pallets packed

- Manual packing cycle mode

- Restart the packaging cycle after removing an error or replacing a roll of stretch film

The control panel can be managed digitally:

- Number of packing cycles

- Turning speed -12 rpm.

- Adjustable photocell delay for film overlay

- Number of wrapping rounds at the top and bottom of the pallet

- Transport speed up and down (separately) 0-5.9 mt/min

Cycles activated by the control panel

- Ascending and descending trolley cycle

- Only the rising cycle of the trolley

Product Features

- Max. Pallet size: d 800 x w 1200 mm (with turntable diameter 1500 mm).

- Maximum height of the packing pallet: 2200 mm.

- Maximum load capacity: 1500 kg.

Properties of stretch film

- Maximum outer diameter of the blade: 280 mm.

- Inner core: 76 mm.

- Height of stretch film roll: 500 mm.

- Maximum film roll weight: 16 kg.

Options

- Turntable diameter 1650 mm (for pallet 1000 x 1200 mm)

- Entrance ramp (for turntable with 1500 mm diameter)

- Entrance ramp (for turntable diameter 1650 mm)

- High arm for a useful packing height of 2600 mm

- Photocell for detection of black products