Semi-automatic wrapping machine on wagon

Winding machine with turntable mod. Easy Wrap 2000 A RC for wrapping trolleys (disc container), with manual clamping and cutting of film and automatic wrapping cycle, height adjustable spool end switches on the base of the trolley for wrapping at the desired height, digital panel with 3 wrapping programs, guide for trolleys, mechanical foot lock, loading ramp for pallet trolleys, inverter for gradual start-up and speed change of the turntable, mechanical brake trolley for film tensioning or powered preload trolley.

New graphical touchscreen interface

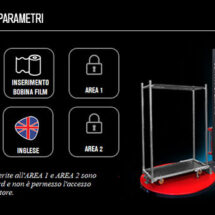

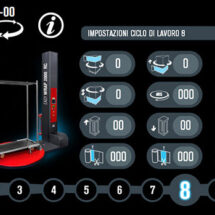

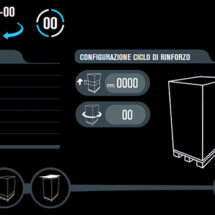

Since January 2021, there have been significant improvements in the use and management of the machine on the user side. In addition to the language selector, the touch screen navigation logic has been updated and simplified to make the most of the potential of this winder. Each screen features an information icon that briefly describes the specification of the on-screen commands, with instant warnings to alert the operator to any anomalies or alarms during work operations. Operations focused on pallet reinforcement cycles and duty cycle settings have been redesigned, giving the ability to manage and store up to 10 different job settings, optimising (based on set values) the considerable savings of stretch film.

General characteristics

The Easy Wrap 2000 A RC pallet wrapping machine has a turntable diameter of 1500 mm (standard) and can handle products with dimensions L. 565 x W. 1350 x H. 2200 mm with a maximum turntable weight of 1500 kg. In addition, the pallet wrapping machine is equipped with PLC electrical panel with 3 winding programs, trolley guide, inverter for progressive start and turntable speed variation, photocell reading delay, cycle counter, etc.

- Machine construction made of painted steel sheet

- Arm folds on the base for easy and quick installation

- Turntable ø 1500 mm

- Maximum product height: 2200 mm

- Ambient humidity conditions: ≤ 90%

- Operating temperature range: +0°C to +40°C

- Machine controlled by PLC and 7,2″ colour touch screen

- Foil trolley fall protection system

- Acoustic wear at the beginning of the cycle

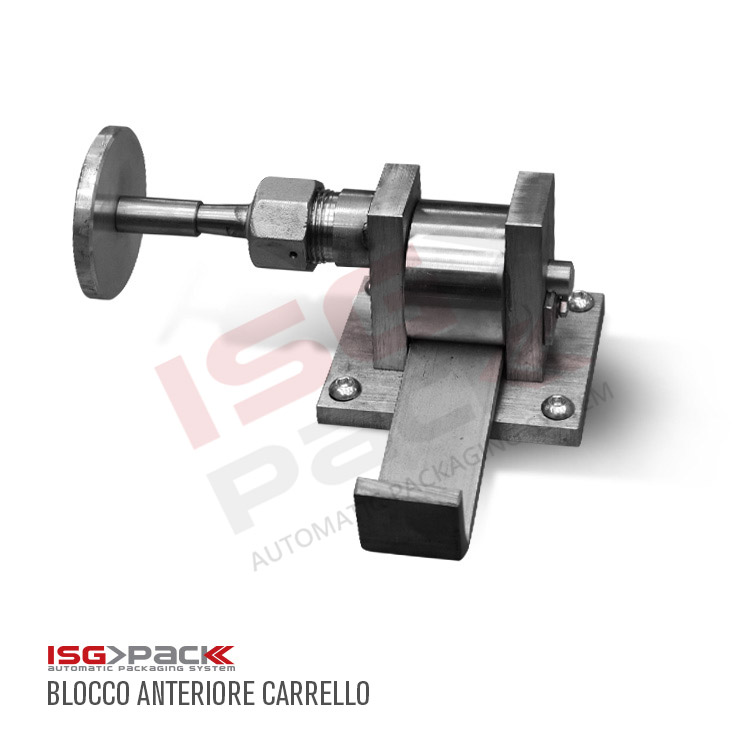

- Mechanical brake

- Emergency stop in accordance with CE regulations

- Front and rear openings for forklift

- Inverter for slow start and indexed turntable stop

Parameters adjustable via control panel

- Number of laps at the bottom

- Number of laps on top

- Adjustable rotation speed of the turntable from 0 to 12 rpm

- Trolley ascent and descent speed

- Adjustable reading delay

- Ascending and descending trolley function

- Cycle counter

Functions activated by the control panel

- Cycle ascending and descending

- Cycle only ascending

- Top sheet function with top and bottom cycle

- 10 programmable packing cycles

Characteristics of the processable product

- Maximum product dimension: l. 565 x w. 1350 mm.

- Usable height: 2200 mm.

- Maximum product weight: 1500 kg.

Properties of stretch film

-

Outer diameter of the foil roll: 280 mm.

-

Inner diameter of the foil roll: 76 mm.

-

Height of the film roll: 500 mm.

-

Maximum disc weight: 16 kg.