A new, better and even more efficient mobile packaging machine

The PKG MOTION 2.0 is the successor to the popular PKG MOTION wrapping robot. Version 2.0 retains all the good features of the original wrapping machine, but introduces some major improvements that will be reflected both in the operation of the machine and in the result of the wrapped products.

- Possibility to integrate the ZEPHYR applicator for fully automatic application of stretch film on the packaged shipment.

- Indication of the device status by multi-colour LED indication.

- Improved ergonomics of the control panel.

- Possibility to disconnect the control panel from the machine and control it remotely by the operator.

- Improved access to the service area and battery storage.

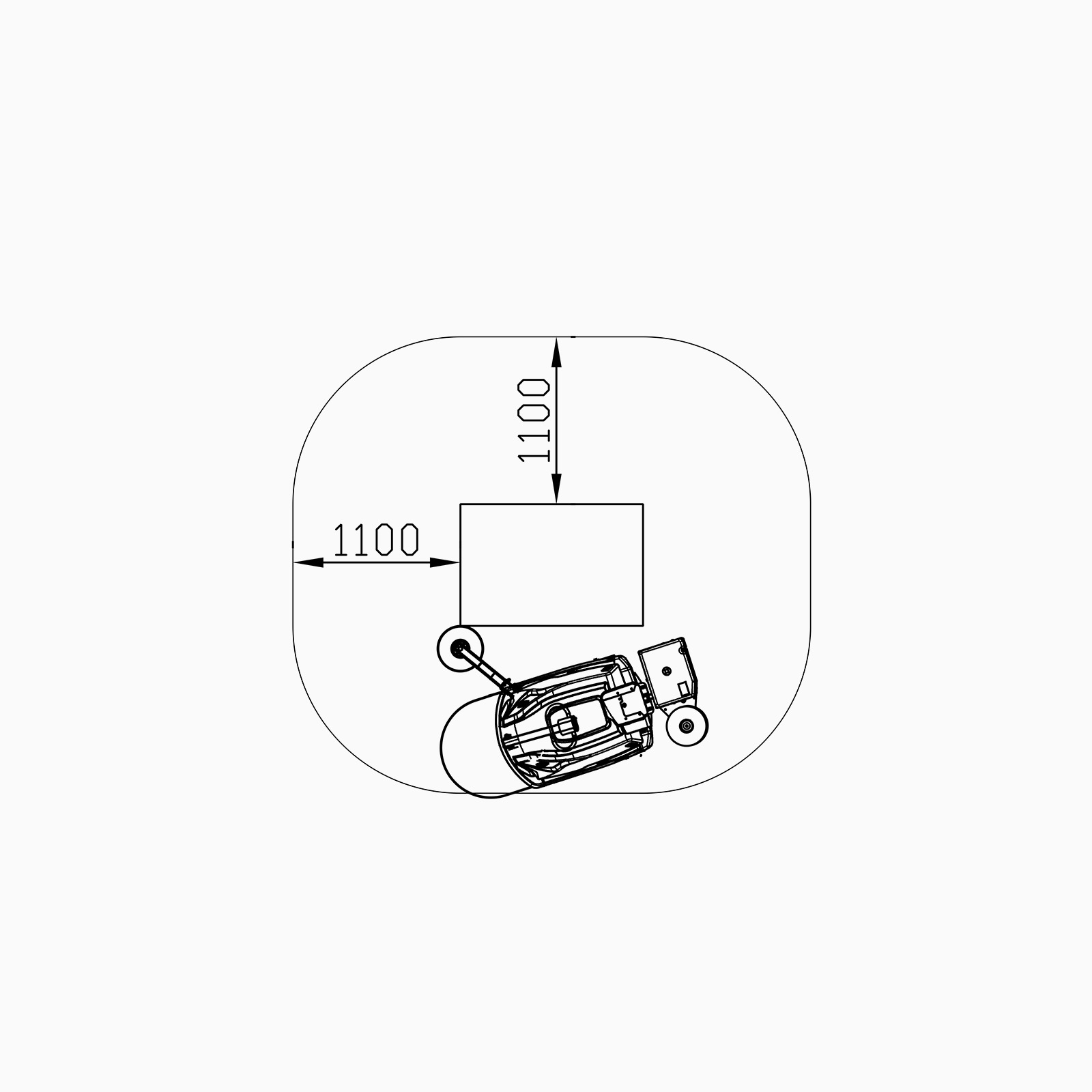

The PKG MOTION 2.0 mobile mobile packaging machine(packaging robot) is battery powered and can be easily moved to the pallet shipment you need to pack. Neither the size nor the weight of the consignment matters when packing. The operator attaches the film to the shipment before packing, selects the packing program and the entire packing process is carried out by the packaging robot autonomously to completion. If equipped with a ZEPHYR applicator, the film is applied to the shipment automatically.

Key features

- Configurable from 6 to 99 packaging programs,

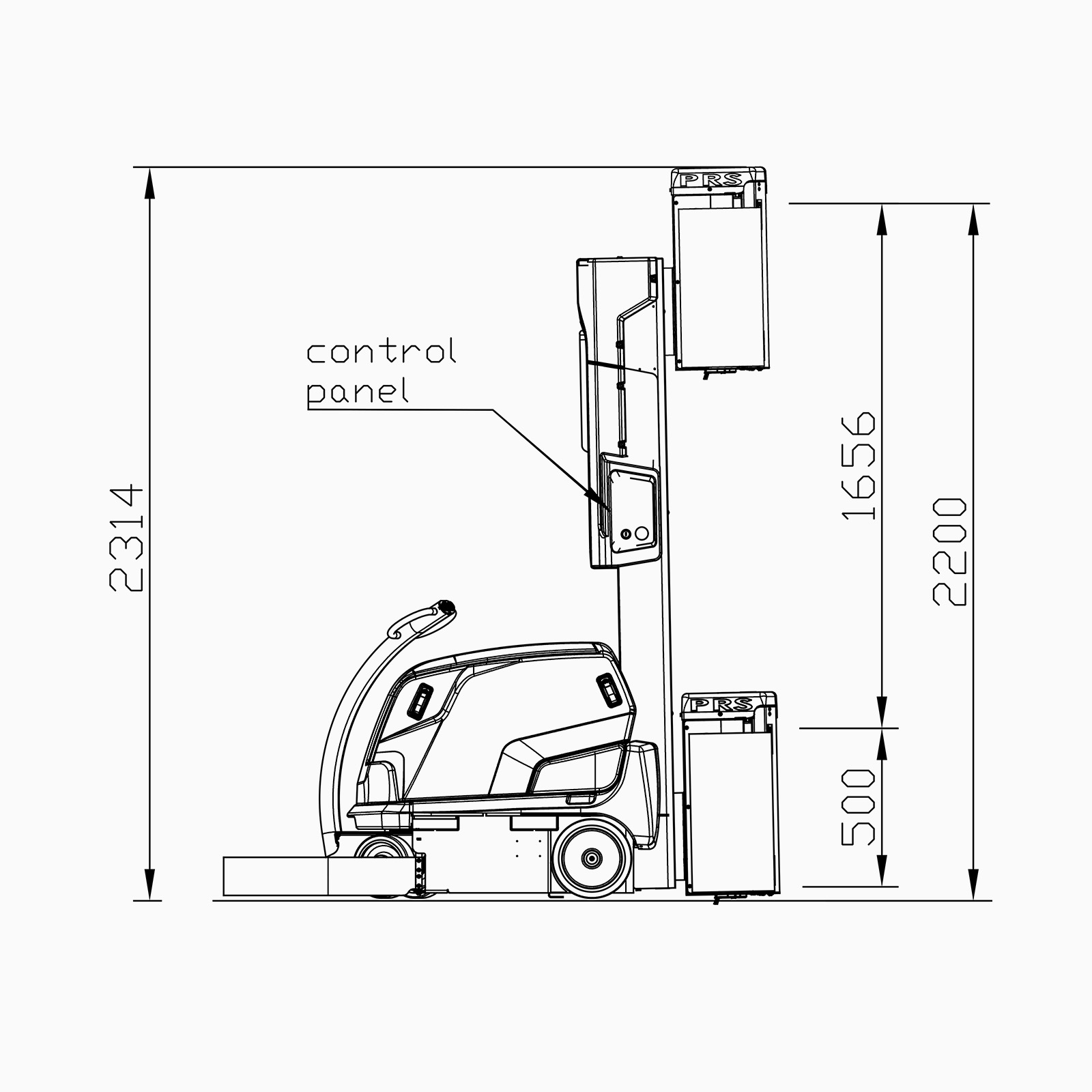

- Standard packing height 2200 mm,

- Photo cell sensing the height of the shipment,

- Foil cut-off unit (optional accessory),

- Light and sound indication of machine status,

- Keypad lock,

- 2x batteries 12V / 110 Ah connected in series,

- Built-in charger directly in the packaging machine,

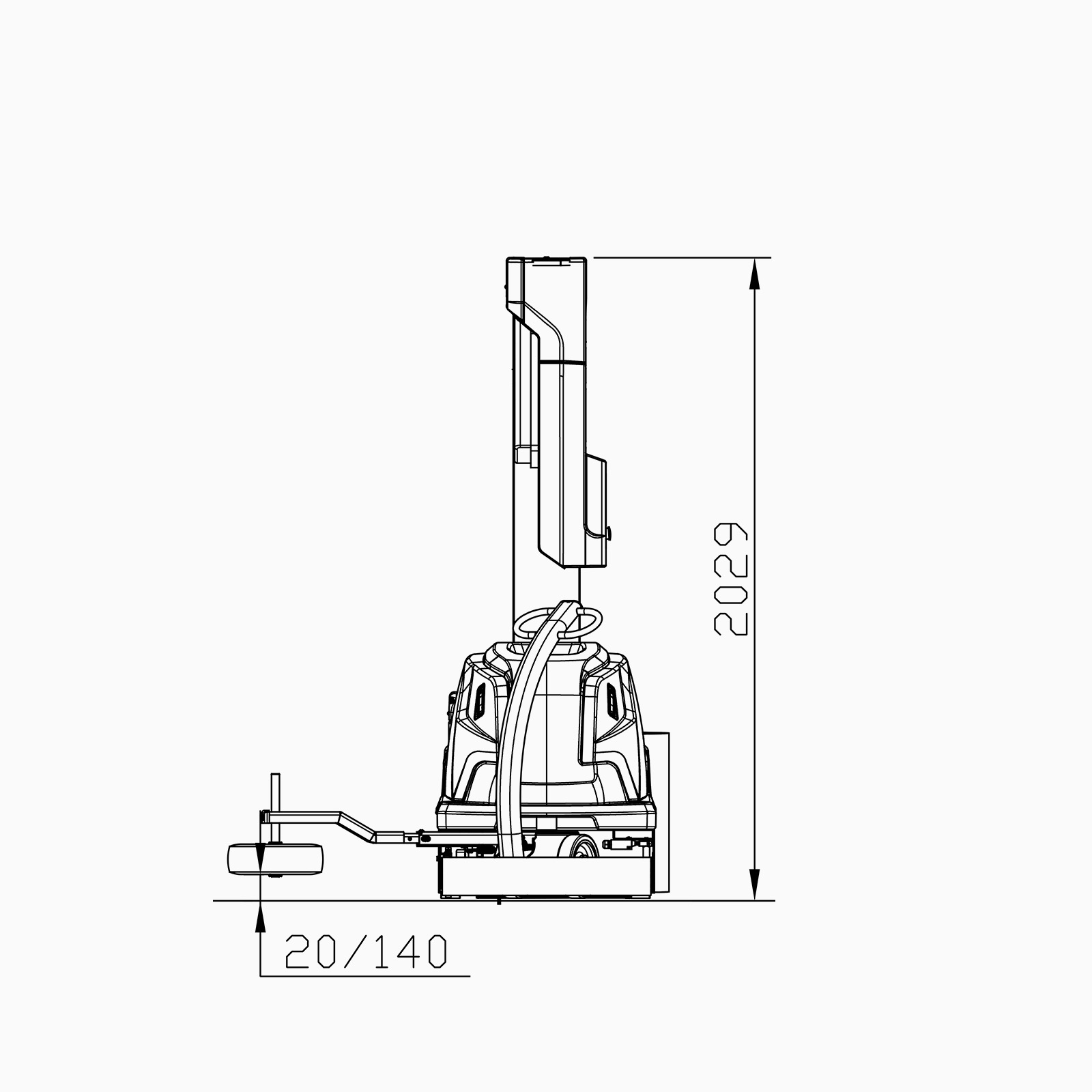

- Handling holes for forklift,

- Guaranteed service and spare parts availability

Package parameters adjustable from the control panel

- The speed at which the machine rotates around the consignment,

- Lift/lower speed of the film trolley,

- The number of packages on the top of the pallet shipment / on the bottom of the shipment (photocell scanning delay),

- Upward/downward tensioning of the film (except for the MB film trolley),

- Foil upward/downward tensioning ratio (only valid for MPS2 trolley),

- Reinforcing overwrapping with foil,

- Activation / Deactivation of the foil cutting (except for the MB foil carriage),

- Start of the packing cycle at the preset height,

- Reinforced wrapping in preset height with the possibility of regulating the number of wraps.

Standard packaging processes selectable from the control panel

- Pack up / pack down,

- Pack up only,

- Pack up / pack down with manual adjustment of start and end position.

Additional functions to standard packaging processes

- Application of the top overlapping foil,

- Packaging with display of operating values,

- Packaging for large pallets,

- Packaging starting from preset height,

- Packing with reinforced overpack in preset height,

- Pack starting from the selected point and stop at the preset height,

- Buttons for manual operation of the machine,

- Multilayer packaging,

- High stability packaging,

- Ergonomic packaging for easy attachment of the foil,

- Eco-friendly packaging.

Configuration options

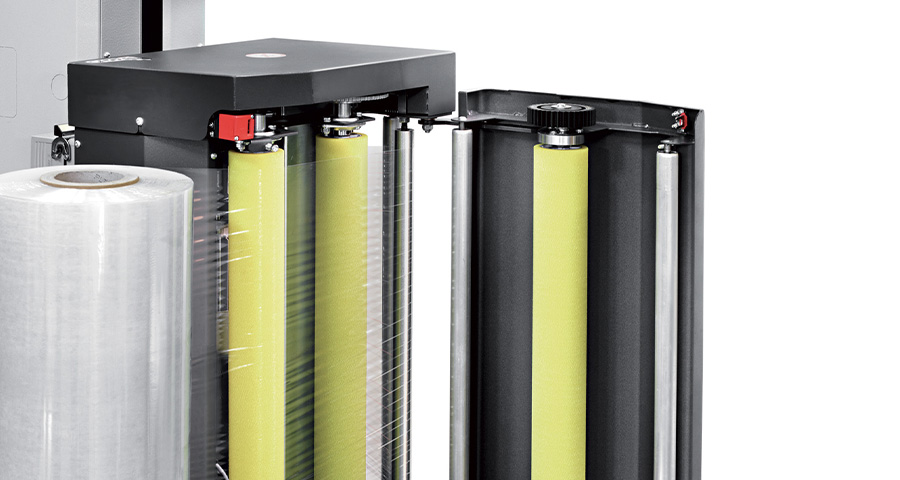

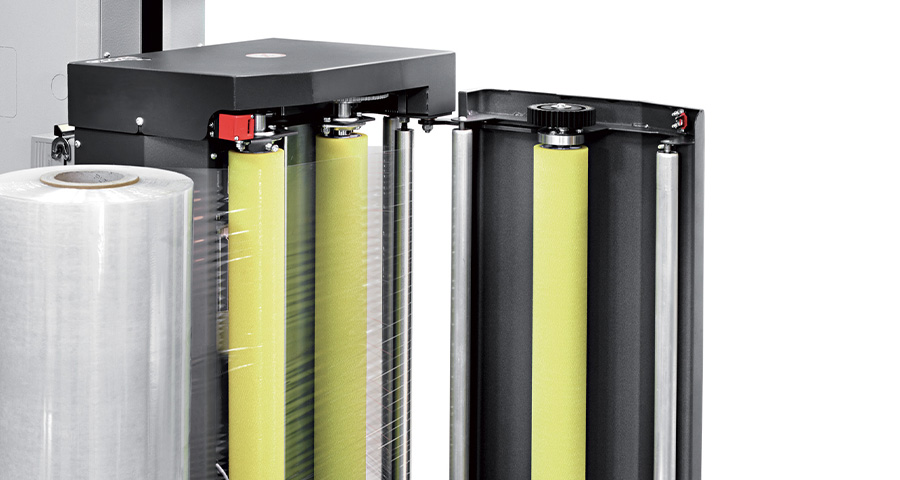

MB mechanical brake – MB foil trolley with mechanical brake

Electromagnetic brake EB – EB foil trolley with electromagnetic brake

Motorised pre-stretching MPS – MPS film trolley with motorised film pre-stretching, switchable film pre-stretching levels

Powerful motorised film pre-stretching MPS2 – MPS2 film trolley with powerful motorised film pre-stretching, with adjustable film pre-stretching level.

Automatic strapping – additional unit for the film trolley for automatic strapping of the consignment

Film applicator ZEPHYR – automatic stretch film applicator on pallet