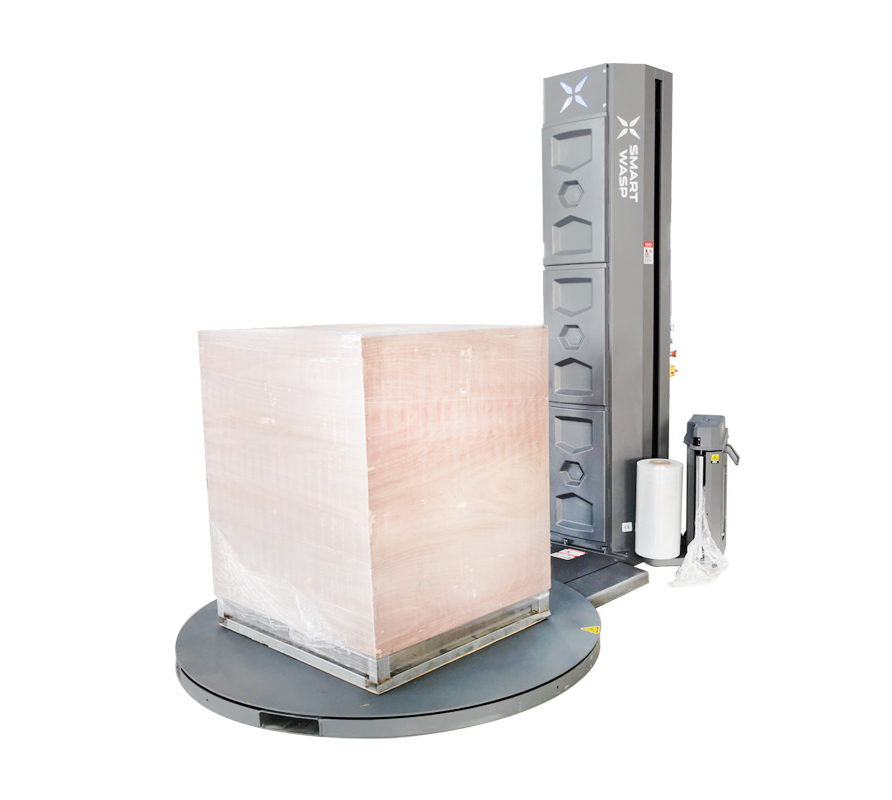

SmartWasp X100 automatic packaging machine

The Smart Wrap X100 automatic wrapping machine is a reliable solution for fast and efficient wrapping of palletized goods in stretch film. It is designed for industrial use in manufacturing, logistics, and food processing, as well as in the glass, electrical, and paper industries.

The device uses highly flexible LLDPE film, which strengthens and protects goods from external influences during storage and transport. The machine features fully automatic operation, including automatic film cutting after the cycle is complete, eliminating the need for manual intervention.

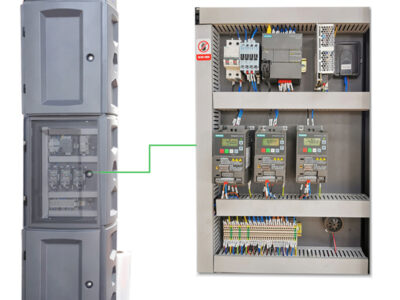

Thanks to the advanced Siemens PLC control system and high-quality components (SICK, AUTONICS, OMRON, WEIDMULLER), it offers a long service life and high reliability. The multi-layer packaging function allows you to set up to 9 levels of film tension for different parts of the pallet, achieving optimal load reinforcement.

Differences between the SMART WASP X100S, X100SW, X100SD, and X100S-MT models

All models belong to the same series and have the same basis, but the differences are in the accessories and purpose:

- X100S – basic model for general use,

- X100SW – with scale for precise measurement,

- X100SD – with top press for light or tall pallets,

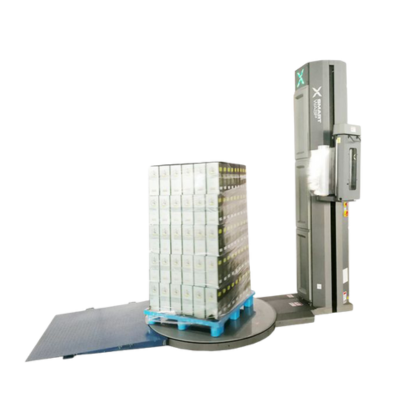

- X100S-MT – with open turntable for pallet trucks

Common specifications (all X100S models)

- Film pre-stretch: 200%

- Turntable diameter: 1650 mm with brake motor Automatic film cutting

- Multi-layer packaging system Adjustable film tension force Power supply: 220 V / 50 Hz

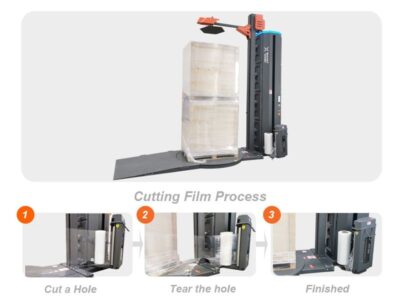

Automatic foil cutting

After completing the packaging of the pallet, our stretch pack will automatically cut off the foil. Workers do not have to cut the film with tools, which is very useful for users

Multi-layer function

This function can set different packaging rings and strengths at any height. The maximum number of layers a Stretch Pallet wrapping machine can set is 9. The packing strength of the normal machine from the bottom up shall be the same and the machine shall not stop during packing in order to increase the packing strength. Such a function completely avoids these problems.

Foil Consumption Saving

- Maximum pre-draw speed up to 380%

- Minimum value of each metre of stretch film

- Standard film with constant release

- Foil for quantitative use with a fixed point

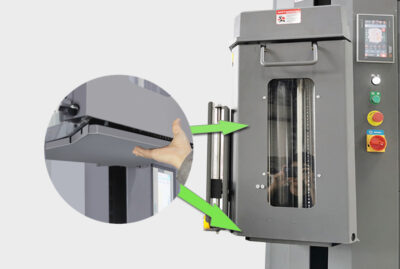

Advanced security technology

- Safety device under the trolley of a film to protect the foot or head of the operator

- A transparent board makes it easier to find a problem without opening the door.

- The belt up-and-down deflection and defect alarm system.

- Setting the alarm early keeps the trolley from crashing.

Better components

- Siemens PLC

- Siemens Invertor

- Sickle button

- AUTONICS Photo Electric Switch

- Weld WIDMULLER

- X-Line shifter

- Omron 24DC power supply

Smart Operating System

1. X100s with LED indicator on machine

- Ready to work – Blue paint

- During work – green colour

- Red Alarm

2. The touch screen accompanies the user on how to operate the machine.

If an alarm is displayed, the touch screen will display instructions on how to solve the problem.

Upper Pressure – Optional

With upper thrust and power, the pressure mass shall be 35 kg.

The pressure can reach 600-2 000 mm, with a cylindrical top contact plate normally used on the market.

Such a pressure can only be 1 200-2 000 mm and an air compressor is required.