SmartWasp XPS Packing Machines

Application of a pallet packer

1. The pallet packaging machine uses the LLDPE foil as the main packaging material for the packaging of the bulk load laid on the pallet.

2. The film provides additional support during transport and storage to protect it from dust, moisture or damage.

3. The pallet packaging machine is widely used in sectors such as glassmaking, tools, electrical and electronic engineering, paper, ceramics, food and beverages, etc.

| Model | Main Function | Specific Features / Differences | Max. Pallet Weight | Max. Wrapping Height |

|---|---|---|---|---|

| X0MS | Basic model with mechanical brake | Mechanical brake, 1500 mm turntable with brake motor, simple operation | 2000 kg | 2200 mm |

| X0PS | Automatic model with electromagnetic brake | 200% pre-stretch, electromagnetic brake, automatic film cutting, 1650 mm turntable | 2000 kg | 2200 mm |

| X0PS-MT | Open turntable – front loading | Front-open platform for pallet jack access, 200% pre-stretch, suitable for lighter loads | 800 kg | 2200 mm |

| X0PS-MTL | Open turntable – side loading | Same specifications as X0PS-MT, but with left-side pallet jack entry | 800 kg | 2200 mm |

| X0PSW | Model with integrated weighing system | Built-in weighing scale + electromagnetic brake, automatic film cutting | 2000 kg | 2200 mm |

Common properties of the X0PS series

- The average is accurate: 1500-1650 mm

- Type of brake: Electromagnetic (except X0MS — mechanical)

- Cutting of film: Automatic

- Power supply: 220 V / 50 Hz

Foil upholstery trolley

- Touch screen accurately sets the packing voltage

- The maximum pre-tensioning ratio may be as high as 350%, saving the quantity of wrapping foil.A. Rubberised cylinder + 300% pre-stretch film, 250% in the market. Save 20% of the cost if you use our machine. Do you understand the foil?B. Pre-tensioning is a normal function.

However, most machines on the market use yellow paint glued to the cylinder because it breaks easily during work and the foil can contract too much. If there is a label on the palette, it will be difficult to scan the bar code of the label.

6 memory functions + start with one printer

Six types of packaging memory functions facilitate parameter setting. Start with one button, make it easier for the machine to operate.

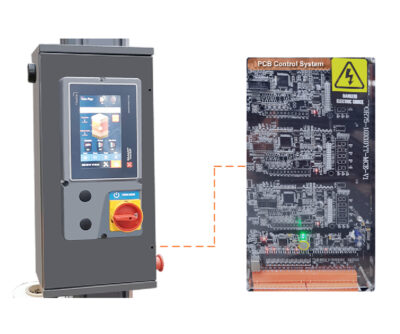

PCB control system

Four independent chips, control, more robust operation and longer lifespan. Integrated circuit system, maintenance is more comfortable.

Aluminium column type all in one

- 4000 tonnes Extruded column, fully formed, solid and resistant

- Modular assembly, simple installation

- Dual chain lift system, greater safety

- Trichromatic LED light

SmartWasp pallet pre-packaging machine — Advanced solution for effective packaging

As a leading manufacturer of pre-stretching pallet packaging machines in China, we bring you a modern and reliable solution for efficient, economical and safe pallet packaging.

Our pallet pre-packaging machine is designed to make your packaging process more efficient, to reduce the consumption of foil while ensuring maximum stability and cargo protection.

Why choose our pallet-wrapping machine with pre-tense?

Our long experience in the production of packaging technologies is reflected in every detail of design and functionality.

The pre-tensioned packaging machine combines accuracy and reliability with innovative foil pre-fitting technology, thereby providing a seamless and cost-effective solution for modern packaging lines.

Key features

Improved cargo stability

The pre-tensioning technology extends the stretch foil before it is applied to the pallet. This results in a firmer load retention, lower foil consumption and lower operating costs – without compromising stability.

Acceptable packaging settings

You can easily adapt the packaging process to the type of goods or to the operational requirements. Adjustable parameters such as tension level, number of turns or packing pattern guarantee an optimal result for each type of load.

An intuitive control

A clear and user-friendly interface simplifies the service, shortens the staff training time and speeds up the entire packing process.

Duration and reliability

The machine is made of high quality materials with emphasis on accuracy and resistance. Designed for long-term operation and under challenging conditions with high load.

Maximum efficiency

Fast and automated packaging with minimal operator intervention increases productivity, reduces downtime and accelerates pallet handling.