Latest X0MS pallet wrapper

Application of a pallet packer

1. The pallet packaging machine uses the LLDPE stretch foil as the main packaging material for packing bulk pallet load

2. The film provides additional support during transport and storage to protect it from dust, moisture or damage.

3. The pallet packaging machine is widely used in sectors such as glassmaking, tools, electrical and electronic engineering, paper, ceramics, food and beverages, etc.

Main characteristics of the pallet packer

- Yarn having a diameter of 1500 mm

- Package height 2000 mm

- Maximum mass of the load: 1500 kg

- Foil prefixation device, high packing efficiency

- Comprehensive security system

Pallet Packing Machine

A pallet-wrapping machine, also known as a packing machine for stretch foil, is a device used in warehouses and distribution centres to secure and protect paletized goods. It serves to firmly wrap the pallet and its contents with stretch film, thus creating a stable and safe unit suitable for both transport and storage.

How does a pallet-wrapping machine work?

Location of cargo:

The load pallet shall be placed on the rotating table or conveyor system of the packaging machine. Most devices are equipped with adjustable guide sheets or pouches to ensure that the pallet is properly aligned.

Foil Seat:

The operator shall attach the end of the stretch foil to the pallet, either manually, usually around one of the lower corners, or by means of an automatic foil attachment system.

Adjustment of parameters:

On the machine ’ s control panel, the packaging parameters are set, such as the number of wrappings, the tension of the foil, its overlap and the rotational speed of the rotating table (if it is part of the system).

Packaging process:

After setting the parameters, the machine automatically starts the package. The swivel table shall be rotated or the trolley with the foil moving vertically, the foil being rolled, stretched and uniformly applied to the pallet.

Cutting and fixing of the foil:

After completing the set number of turns, the machine cuts off the foil and attaches it to the pallet, either by thermal welding or simply pressing the layers together to form a solid joint.

Removal of pallet:

At the end of the cycle, the packaged pallet is removed from the machine to prepare room for the next one.

Advantages of pallet packaging machines

- Cargo stability:

Solid packaging prevents the movement or tipping of goods during handling and transport, thereby minimising the risk of damage. - Protection of goods:

The stretch film shall provide protection against dust, moisture and other external influences which could adversely affect the quality or integrity of the goods. - Increased efficiency:

Process automation significantly saves time and reduces the physical effort of operators compared to hand packaging. - Cost savings:

The optimum tension of the film and the precise amount of material used help to reduce the consumption of the film and thus the overall cost of packaging.

Types of pallet packer

There are several types of packaging machines, for example:

Rotating table machines — suitable for normal storage operations,

Rotary arm machines — designed for heavier or unstable pallets,

Orbital packaging machines — suitable for long or specifically shaped products.

The selection of a particular type depends on the volume of the packaging, the size and weight of the pallets as well as the specific requirements of the plant.

The parameters and functions of the packaging machines may differ according to the manufacturer and the model. It is therefore important to familiarise yourself with the user manual of a particular device or to contact the manufacturer for detailed instructions on operation and maintenance.

New generation of mechanically resistant foil trolley

A button with physical feedback and tension is more comfortable to set. Gradient modifications for a more even film.

6 memory functions + start with one printer

The six types of memory function of the packaging facilitate the setting of parameters. Starting with a single button allows the machine to operate more comfortably.

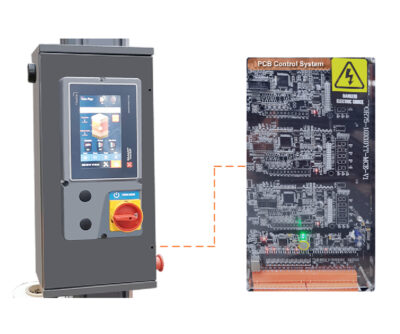

PCB control system

Four independent chips, control, more robust operation and longer lifespan. Integrated circuit system, maintenance is more comfortable.

Aluminium column type all in one + lifetime guarantee

- 4000 tonový stĺp, integrálne tvarovaný, pevný a odolný

- Modulárna montáž, jednoduchá inštalácia

- Dvojitý reťazový zdvíhací systém, väčšia bezpečnosť

- Trojfarebné LED svetlo