Efficient horizontal baling for demanding operations

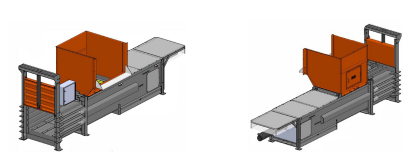

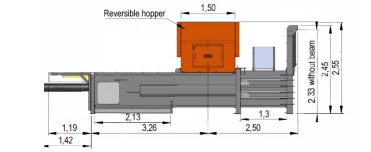

The ORWAK 1540, 1550 and 1560 models represent the latest generation of semi-automatic horizontal balers, designed for companies with high production of recyclable raw materials. They are the ideal solution where handling with vertical balers is inefficient or where bulk and continuous material feeding is required.

High compaction in a closed baling chamber

The waste is pressed into a closed chamber, which ensures a stable process and the creation of highly compacted bales weighing up to 400 kg (depending on the material). The result is a significant reduction in waste volume and easier handling during storage and transport.

Flexible filling options

The ORWAK 1540-1550–1560 horizontal balers offer a wide range of filling options to suit your needs:

- manual filling

- floor or floor filling

- container lift

- hopper or conveyor

- forklift

This flexibility allows for easy integration into existing logistics processes.

Time, space and cost savings

The high baling force of 40, 50 or 60 tonnes ensures strong compaction of the waste, which:

- reduces the number of collections

- optimises transport costs

- reduces CO₂ emissions

- increases the quality of the raw material for recycling

At the same time, a clean, safe and passable working environment is maintained.

Reliable semi-automatic operation

The balers are equipped with a trap door as standard and manual bale tying, which provides a good balance between automation and process control. The robust construction guarantees a long service life even with intensive use.

Main advantages:

- Balsing force 40, 50 or 60 tons depending on the model

- Highly compacted bales up to 400 kg

- Closed baling chamber for a stable process

- Many filling options and easy integration

- Lower logistics costs and space savings

Related and recommended links

Internal links

See also other products in the Horizontal balers

External link

More about Orwak products can be found on the official Orwak website