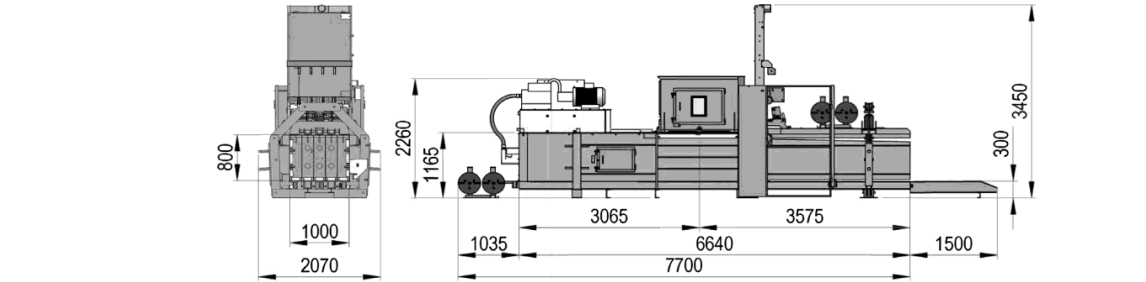

Industrial solution for massive waste volumes

The ORWAK 500 automatic baler represents the pinnacle of efficiency when processing large quantities of recyclable materials. This machine is specially designed to handle the continuous pressure of industrial operations and transform huge piles of bulk waste into highly compacted, clean bales of raw material.

Industrial strength and continuous operation

With an impressive pressing force of 50 tons, the ORWAK 500 AT automatic baler is capable of processing 2 to 4.5 tons of material per hour. Thanks to its proven continuous pressing technology and fully automatic binding system, the machine is designed for intensive multi-shift operation. It allows companies to process waste continuously without having to interrupt production or shipping processes.

Exceptional bale density for maximum profit

One of the biggest advantages of the ORWAK HORIZONTAL 500 AT automatic baler is its ability to produce extremely compacted bales weighing up to 600 kg. The high bale density brings three major advantages:

- Excellent logistics: Maximum truck utilization when transporting raw materials

- Lower costs: Radical reduction in the number of necessary collections and the associated CO₂ emissions

- Increased income: High-quality compressed bales are highly valued by the recycling industry, which guarantees better purchase prices for your secondary raw materials

Versatile and integration options

The 500 AT is not just a cardboard baler. Its versatile design easily handles a wide range of materials, including stretch films, PET bottles, paper bags, shredded paper and even light wooden boxes or aluminum cans. To make the machine fit perfectly into your logistics chain, it offers various filling systems:

- Conveyor belt for fully automated material feed

- Container lifter for efficient emptying of collection bins

- Pneumatic technology for integration into pneumatic conveying systems

- Manual filling via a large hopper opening

Safety and productivity first

By investing in the ORWAK 500 AT automatic baler technology, you not only get a powerful machine, but also a cleaner and safer working environment. By quickly processing waste directly at source, you keep aisles clear, reduce the risk of fire and free up valuable floor space for your core business activities.

Main advantages:

- 50 ton force: Extreme compaction for the heaviest bales on the market (up to 600 kg)

- Fully automated process

- High capacity: Ready to process up to 4.5 tons of raw material every hour

- Adaptability: Electronically adjustable bale length according to your logistical needs

The ORWAK 500 AT automatic baler is an investment in professionalism and sustainability that will transform your waste into an efficiently managed and profitable resource.

Related and recommended links

Internal links

See also other products in the Horizontal balers

External link

More about Orwak products can be found on the official Orwak website