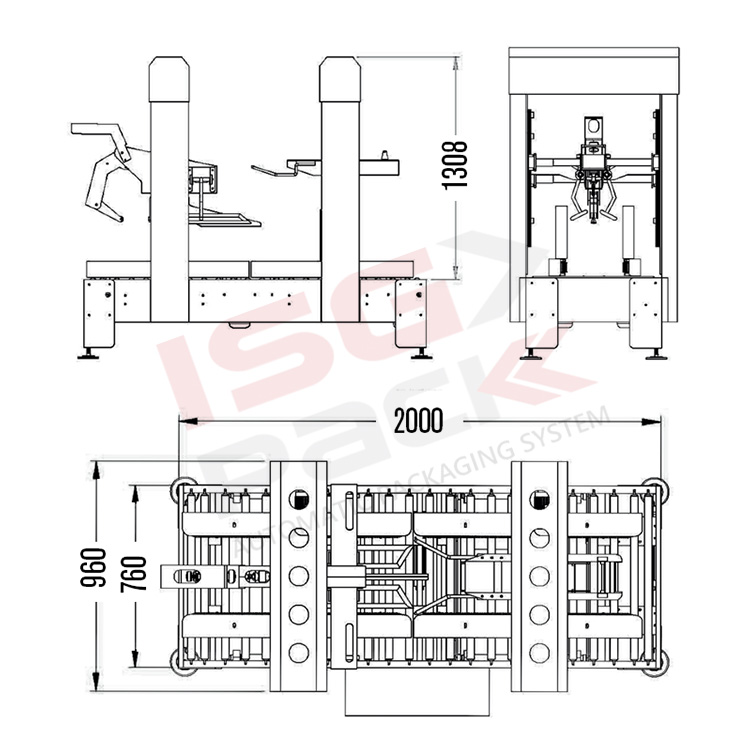

Automatic and self-dimensional carton welder with flap closing system

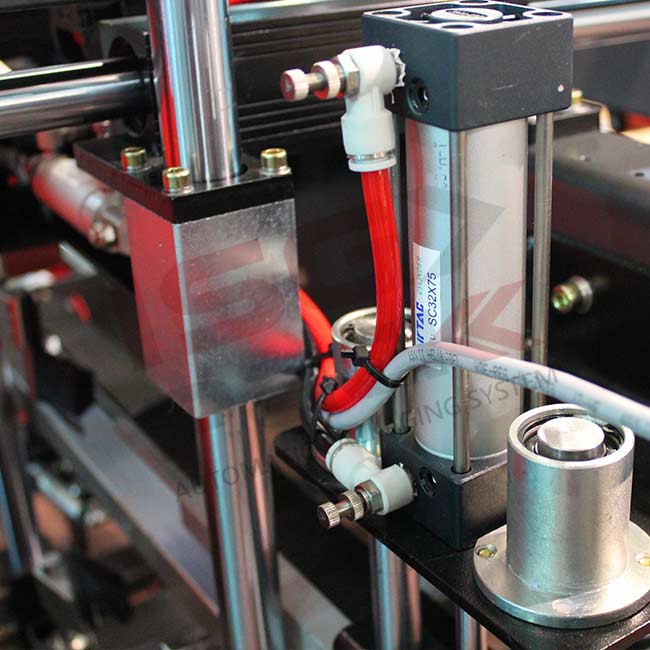

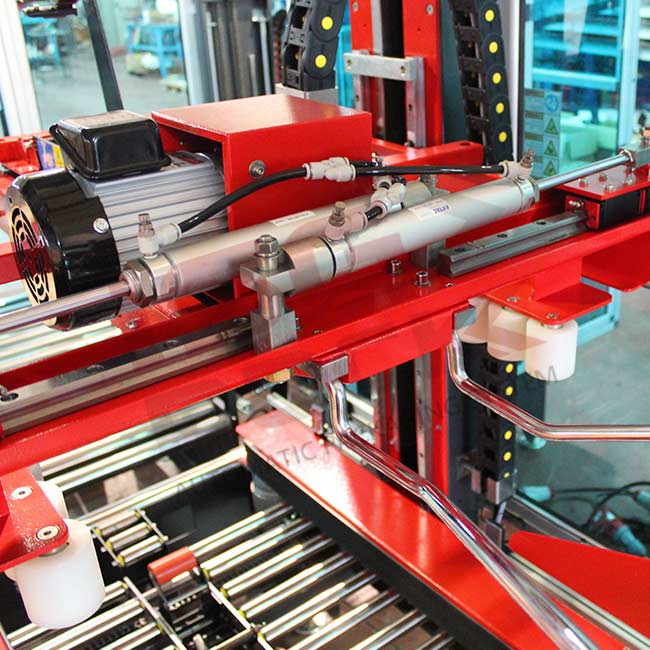

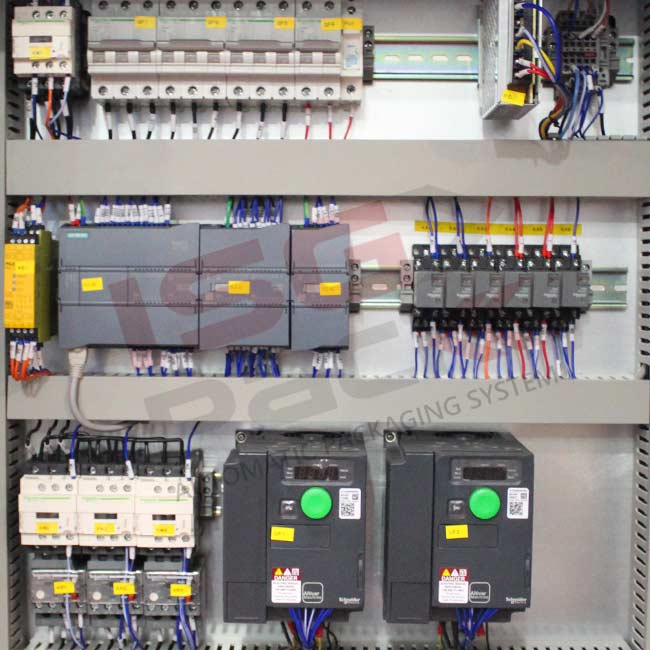

Automatic and self-dimensional carton welder with flap closing system. It folds the four top flaps and automatically seals the top and bottom American-style variable size carton. For use on fully automatic, unattended lines. Machine construction of bent, welded and painted steel plate. Box feed is controlled by four side bottom belts operated by four motors. The machine adjusts itself to the boxes, automatically folds the four top flaps and seals them. Pneumatic actuators and an electronic system controlled by SIEMENS plc. It is a simple and practical packing station equipped with infeed and outfeed rollers.

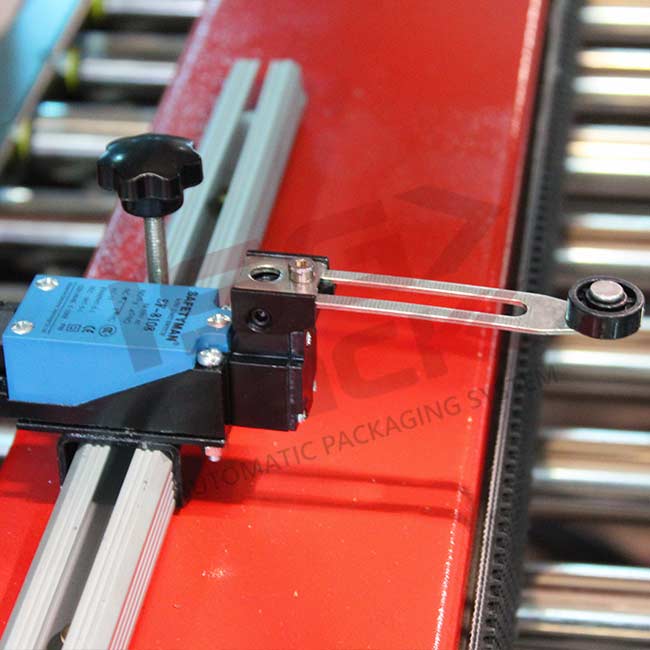

Cadence and centering device

On this automatic tape machine Matic Tape 50 CF it is possible to replace the feed roller conveyor by inserting an automatic centering device / cadence, which by installing special sensors located on the conveyor belt guide of the boxes allows the cadence when the machine feeds the cartons to be taped.

Features

- Weight: 820 kg

- Power supply: 380 Volt 50/60Hz

- Ambient humidity conditions ≤ 90%

- Box transmission speed: 19 m/min

- Air supply: ≥4kgf/cm2

- Application temperature: +0°C to +40°C

- Maximum box weight: 35 kg

- Maximum noise level: 75 dB

- Electrical protection: IP 54

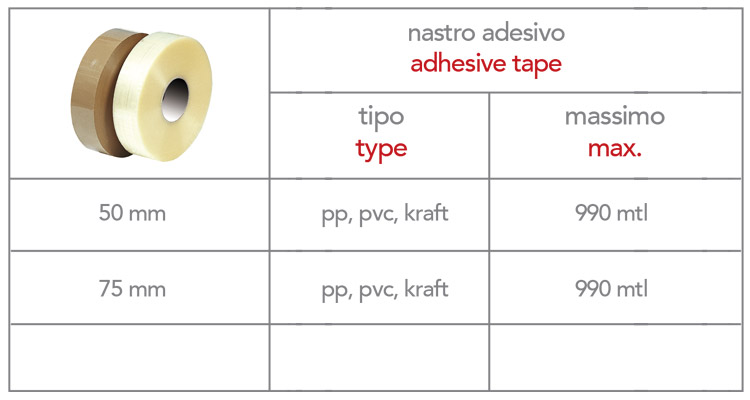

- Adhesive tape: Kraft, polypropylene, PVC

- Standard taping head: 50 – 75 mm

- Workbench height: 550 – 750 mm

- Installed power: 1.20 Kw