Rotary arm pallet wrapper allows you to wrap shipments without weight restrictions while keeping it stationary on the ground

The advantages of the Rotary Wrap 2300 B Rotary Arm Pallet Wrapper with Drive Wheel are remarkable, because starting and stopping is without play and without inertia, plus there is no need for rigid guards against accidents, because the self-braking motor in combination with the front bumper immediately stops the rotation at the slightest contact with an obstacle. The machine design is balanced and requires fixing to the floor. The swing arm system allows for the safe packing of heavy and light loads and, in the case of particularly unstable products.

General characteristics of pallet wrapping machine

The Rotary Wrap 2300 B pallet wrapping machine can handle products with dimensions of d1000 x w1200 x h2000 mm and with a load capacity of unlimited shipment weight. In addition to the possibility of regulating the number of rotations at the bottom and top of the pallet, the gradual start of rotation of the rotary arm can also be regulated via an inverter. The machine is equipped with a PLC and a 7.2″ color touch screen display that allows setting additional parameters such as the carriage ascent and descent speed, photocell reading delay, cycle counter, etc.

- Machine construction made of painted steel sheet

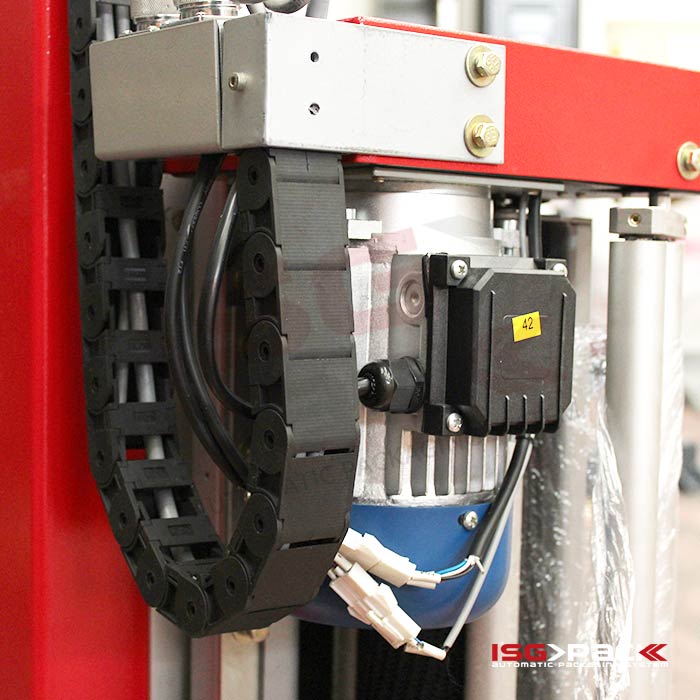

- Conversion of a winch truck with chain mechanism

- Turntable diameter ø 2000 mm

- Machine control via PLC and 7.2″ touch screen

- Safety stopping device over the bumper according to CE regulations

- Brake on/off device to facilitate the attachment of the film to the pallet base

- Acoustic warning at the start of the cycle

- Motorized preload with fixed ratio 200% variable with 2 gear change 100%, 150%, 250%

- Emergency mushroom for CE regulations

- The machine reset button is in operation according to CE regulations

- Inverter for progressive start and indexed pivot arm stop

- Cycle counter

- Manual machine control mode

Parameters adjustable from the control panel

- Digital speed adjustment at the bottom of the pallet

- Digital speed adjustment at the top of the pallet

- Adjustment of arm rotation speed from 0 to 15 rpm.

- Trolley speed adjustment up/down

- Adjusting the number of complete cycles

- Adjusting the indexing time of the rotary arm

- Digital Film Edge Adjustment

Cycles activated by the control panel

- Cycle ascending and descending

- Cycle ascending

- Ascending and descending cycle of “energy saving film mode”

- N°10 programmable packaging cycles

Characteristics of the processable product

- Max product dimension: d 1000 x w 1200 mm.

- Usable height: 2200 mm.

- Maximum product weight: no limit.

Features film roll

- Maximum external dimensions: 280 mm.

- Internal dimensions of the foil: 76 mm.

- Film height: 500 mm.

- Maximum winch weight: 16 kg.

- Film thickness: 12-35 mm