Semi-automatic strapping machine MK60S

The MK60S strapping machine is a reliable and efficient solution for companies that need to secure a smaller number of packages without compromising on quality. This model is the ideal choice for smaller operations, warehouses, or packaging facilities where simplicity, time savings, and precise strapping are required.

Characteristics and functions

- Semi-automatic operation: After manually wrapping the tape around the package, the machine automatically tightens, seals, and cuts the tape using heat sealing.

- Easy to use: No guide frame is required – the operator simply inserts the tape and the machine does the rest.

Speed and accuracy: Strapping is fast, reducing the time needed to secure goods. - Versatile use: Suitable for packaging cartons, parcels, bundles, and products in various industries – from logistics to light industry.

Advantages of the MK60S semi-automatic strapping machine

- Efficient strapping: Increases packaging speed and consistency, saving working time.

Secure fastening of goods: Ensures secure and reliable closure of packages without damaging the contents. - Minimal maintenance: Robust construction and high-quality components ensure a long service life.

- Economical operation: Low energy consumption and simple servicing reduce operating costs.

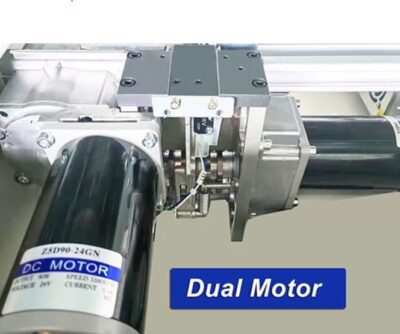

Durable sealing head

Japanese technology sealing head

Double unidirectional motor > 30,000 times

Durability and quality of construction: Since semi-automatic strapping machines are designed for industrial use, they often feature a robust construction and durable components that can withstand demanding operating conditions.

Easy to use

- Automatic strap dispensing

- Soft retractable straps during operation

- Intuitive controls and interface make it easy for the operator to set up and operate the machine efficiently.

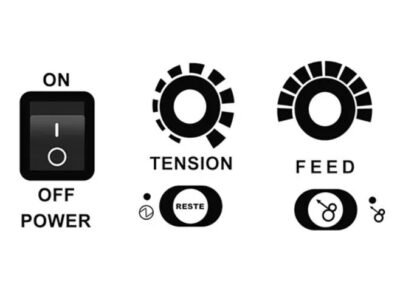

Easy setup

Electric tension adjustment

Electric fastening length adjustment

Allows users to adjust the tension of the strap according to the requirements of the package, ensuring secure but not overly tight strapping. Semi-automatic PP strapping machines can typically handle a variety of plastic strap widths, allowing for flexibility when packaging items of different sizes. An efficient strap feeding system ensures smooth and consistent feeding of the plastic strap, reducing the risk of jamming or breakage during the strapping process.

Sealing mechanism

Semi-automatic strapping machines typically use a heat sealing mechanism to securely join the ends of the plastic strap.

Safety

These may include features such as emergency stop buttons or sensors that prevent injury or damage to the machine.