New R600 robotic packaging machine

The R600 machine from Smart Wasp (and under various names/variants) is a mobile robotic wrapping machine designed for automatic wrapping of pallets with stretch film, offering several advantages over conventional wrapping equipment.

Its characteristic features include:

- Mobility & autonomous movement – the machine moves around the pallet and does not need to be fixed in place.

- No pallet/load weight restrictions – the machine is designed so that there is no limit on package weight.

- High film pre-stretch – typically 350% pre-stretch, which helps save film and improve load stability.

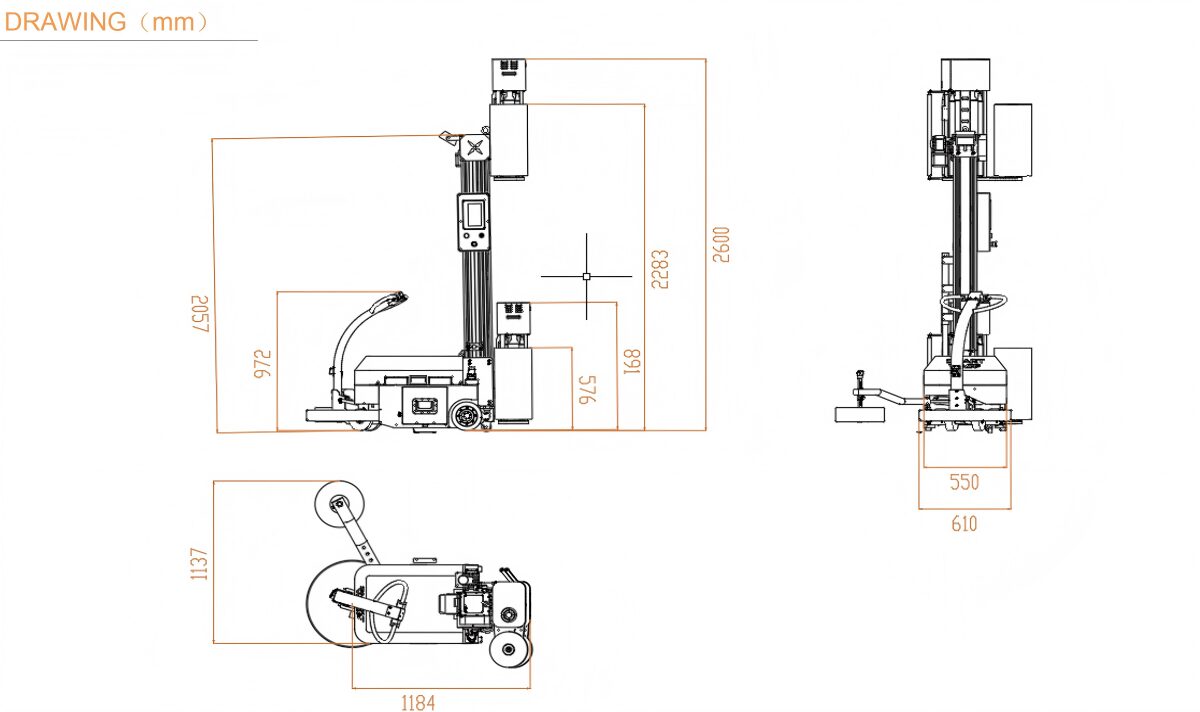

Package height up to ~ 2,800 mm (depending on version) - Battery power – operates without the need for a direct connection to the power supply during packaging. Speed & movement – vertical/lifting movements, movement on the floor, possibility to set the cycle speed.

- Safety features – radar sensors, LED indicators, mechanical sensors for collision protection.

- Quick installation – reportedly can be installed by one person in a few minutes.

- Suitable for various industries – food, beverages, chemicals, textiles, logistics, machine manufacturing, etc.

Advantages

- Flexibility & mobility – just place the pallet, the machine arrives, wraps it and leaves.

- Material savings – high film tension means lower consumption while maintaining strength.

- Less space required – does not require large frames or tracks, works independently.

- No weight restrictions – also suitable for very heavy pallets.

- Safety – sensors prevent collisions, protecting operators.

- Quick configuration – relatively quick installation and commissioning.

- Suitable for retrofitting – can be integrated into existing production lines.

Využitie

- Production plants where there are many pallets every day.

- Logistics centers and warehouses.

- Industries with diverse types of cargo (hard, tall, irregular shapes).

- Places where manual labor needs to be reduced and packaging reliability increased.

GuideWasp™ AI Assistant

Interactive operator instructions: Detailed instructions, real-time troubleshooting, and battery management alerts.

12 pre-programmed baling recipes: Customize them for cylindrical, irregular, and heavy loads.

Machine operating status guide with LED light

FastWasp™ power system

60-second quick-change battery: Hot-swappable modules for uninterrupted packaging.

20% faster packaging speed: High-performance brushless DC motor optimizes cycle times.

5-minute installation: Single-operator setup speeds deployment.

SafeWasp™ 3.0 Radar

Multi-layered safety protection:

- Rainbow warning lights indicate safe areas

- Safety radar sensor, NON-contact barrier to stop the machine

- Mechanical safety sensors serve as a final safety guarantee

- Safety sensor on film cart for film replacement

- Maintenance-free, safe and sealed acid battery

- No transport restrictions

- Enable battery charging in the work area

Applications of the R600 robotic

- Logistics and warehousing: Secure pallets for long-distance transport.

- Food and beverages: Hygienic packaging of perishable products.

- Medicines: Precise packaging of medical supplies.

- Manufacturing: Protection of industrial equipment from heavy loads.

Safety precautions during maintenance

- Battery care: Charge it at designated locations; follow the charging cycles with artificial intelligence.

- Sensor maintenance: Clean radar and mechanical sensors regularly to prevent dust accumulation.

- Motor system: Check the brushless DC motor every quarter to see if it’s worn out or lubricated.

- Film cartridge: Check the safety sensor before replacing the film.

- Software updates: Update GuideWasp™ AI regularly to improve performance.

Important components

- Brushless DC motor: High-efficiency design with long life and 20% increase in speed.

- GuideWasp™ touchscreen display: Intuitive control panel for recipe selection and diagnostics.

- SafeWasp™ radar sensors: Contactless detection updated to version 3.0 for greater accuracy.

- Status LED panel: Multi-color indicators for real-time health and safety alerts.

- FastWasp™ battery system: Lightweight, modular batteries with quick-change capability.