Fully automatic packaging machine Smart Wrap X100

The fully automatic Smart Wrap X100a wrapping machine is a modern solution for companies looking for maximum efficiency, labor savings, and precise packaging of palletized goods.

The device uses LLDPE stretch film, which creates a strong protective layer during packaging, ensuring the stability of the load during transport and storage. The film also protects the goods from dust, moisture, and mechanical damage.

Automatic functions – such as gripping, cutting and securing the film, photoelectric detection of pallet height and automatic turntable reset – ensure completely unattended operation. The machine is equipped with Siemens PLC control, a frequency converter and a soft start and stop system for maximum load stability during packaging.

Key features of the Smart Wrap X100 model

- Fully automatic operation – no manual intervention required.

- Automatic gripping, cutting, and sealing of the film – for a smooth packaging cycle.

- A photoelectric sensor automatically detects the height of the pallet.

- Film pre-stretching up to 300% – material savings and even tensioning.

- Smooth start and stop – safe packaging even for unstable pallets.

- Automatic reset of the turntable after completion of the cycle.

- Siemens PLC control system – reliability and long service life.

- Optional ramp and weighing module.

- Suitable for heavy loads up to 2000 kg.

- Remote control and monitoring option.

SMART WASP X100 series of automatic packaging machines

| Model | X100A | X100AR | X100AW | X100AD |

|---|---|---|---|---|

| Model Type | Standard model | With electric roping system | With integrated weighing scale | With top press plate |

| Main Function | Automatic film clamping and cutting, 200–300% pre-stretch | Electric film roping for tighter and more secure wrapping | Integrated weighing system built into the turntable | Stabilization of light or tall pallets during wrapping |

| Suitable For | General pallet wrapping | Loads requiring extra load securing | Logistics operations that require pallet weighing | Light, unstable, or tall pallets |

Automatic cutting and clamping of foil

The X100a automatic film cutting and clamping wrapping machine allows workers to manually cut and place film on pallets, while the film cutting and clamping system does this automatically.

Pallet gripping system

- Pallet gripping system: the bottom part of the film is narrowed into a film rope, gripping the film rope to the pallet and products during packaging.

- During transport, you do not have to worry about the products falling when the pallets vibrate violently.

- If a forklift damages the film on the bottom of the pallet, the film will not tear.

- Instead of a horizontal strapping machine, a pallet bottom gripping system and a rope gripping system can be used along the entire route.

Film consumption savings

- Maximum preliminary stretch speed up to 380%

- Minimum value for each meter of stretch film

- Standard stretch film with constant release

- Film for quantitative use with a fixed point for packaging

Multi-layer function

This function allows you to set different wrapping circles and wrapping strength at any desired height. A maximum of 9 layers can be set on one pallet. The wrapping strength of conventional machines from bottom to top is the same on the market, and they cannot stop or achieve a reinforced wrapping function during wrapping.

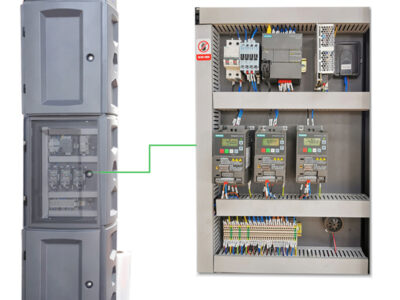

Better components

- SIEMENS PLC – Contactless switch SICK

- Photoelectric switch AUTONIC – Terminal block WEIDMULLER

- SIEMENS Inverter – Power supply OMRON 24DC

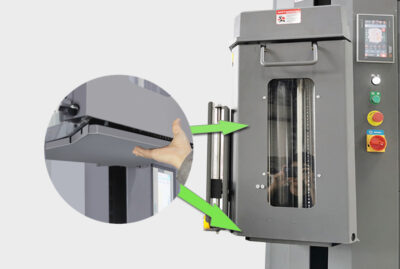

Advanced security technology

- Safety device under the film carriage to protect the operator’s feet or head

- Transparent panel makes it easy to find the problem without opening the door

- Alarm system signals belt deviation up and down and damage. Early alarm activation prevents the carriage from falling.

Intelligent traffic management system

1. Smart Wasp X100a with LED indicator on a fully automatic pallet wrapping machine

- Ready for operation – Blue

- During operation – Green

- Alarm – Red

2. The touch screen guides the user through the operation of the fully automatic pallet wrapping machine.

If an alarm is displayed, the touch screen shows instructions on how to resolve the issue.

Equipment with the highest pressure

An electric pressure system is used to prevent scattering and shifting during the winding of goods, and the stroke of the pressure system is 500 mm to 2,000 mm. Compared with traditional pneumatic pressure, the range is doubled, which is suitable for a wider range.