Fully automatic pallet wrapping machine X100a-MT with turntable model E

The fully automatic Smart Wasp X100a-MT (Model E) packaging machine is a modern solution for companies looking for high speed, labor savings, and minimal operating costs. This model uses an E-type turntable, which allows for easy loading of pallets directly with a pallet truck without the need for a ramp or forklift.

The machine uses LLDPE stretch film to securely and reliably wrap goods on pallets. The automated system ensures that the entire process – from gripping and stretching to cutting and sealing the film – is carried out without the need for manual intervention.

The X100a-MT model is designed for seamless integration into new and existing production lines and achieves a throughput of up to 35 pallets per hour with a load capacity of up to 2000 kg.

Key benefits of the X100a-MT model

- Fully automated packaging process – no manual work.

- E-type turntable – easy loading of pallets with a pallet truck.

- Integration into production lines – suitable for automated operations.

- High packaging speed – up to 35 pallets/hour.

- Load capacity up to 2000 kg – also ideal for heavy or unstable loads.

- 300% film pre-stretch – significant material savings.

- Siemens PLC control – reliable performance and long service life.

- Remote control – the operator can start packaging directly from a forklift.

- Easy maintenance and low operating costs.

- Optional accessories: ramp, scale, extended column.

Benefits for operations

- Reduction in manual labor – operators can devote their time to other tasks.

- Increased productivity – smooth process without downtime.

- Safe handling – minimization of the risk of damage to goods.

- Fast return on investment – lower labor and film costs.

Turntable type E

The fully automatic Smart Wasp X100a-MT pallet wrapping machine is equipped with an E-type turntable designed to simplify the loading process. The E-type turntable allows for easy loading of pallets using a pallet jack, eliminating the need for additional lifting equipment and reducing setup time.

Automatic cutting and clamping of foil

Thanks to the automatic cutting and clamping function of the X100a-MT model, manual handling is no longer necessary. This fully automatic pallet wrapping machine with a turntable automates the cutting and clamping process, eliminating the need for workers to manually attach the film to each pallet. This feature increases efficiency and reduces the risk of injury, making it an ideal choice for high-volume operations.

Remote control system

The X100a-MT pallet wrapping machine also includes a remote control system that allows operators to start the wrapping process at the touch of a button. Forklift operators can remain seated, load the pallet onto the turntable, and activate the fully automatic pallet wrapping machine with turntable remotely. This feature increases productivity by reducing the time operators spend away from their main tasks.

Touchscreen LCD operating system

The SMART WASP pallet wrapping machine uses an intelligent IoT touch screen with perfect response and functionality. The touch screen allows you to directly set the “rotation speed, up and down feed speed, and film carriage speed,” and we also offer 6 pallet wrapping models for our customers. Most customers have different pallets for packaging, so different pallets require different packaging speeds and packaging forces. The customer only needs to set up the 6 models at once and then select the right model for the pallet, so they no longer need to adjust the parameters each time.

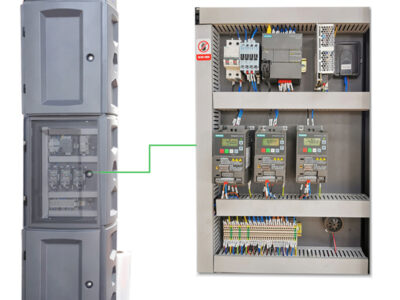

We use components from reputable brands

To ensure long-lasting performance, the fully automatic pallet wrapping machine with a turntable is manufactured from components sourced from reputable brands. The use of high-quality electrical components minimizes the risk of breakdowns and ensures trouble-free operation over time. Each part is selected to maximize the machine’s service life, providing users with a durable and reliable standard pallet wrapping machine for many years to come.

- SIEMENS programmable logic controller

- SICK Switch

- AUTONICS photoelectric switch

- WEIDMULLER terminal block

- SIEMENS Inverter

- OMRON supplies

Alarm system

Safety is a priority in the design of the fully automatic pallet wrapping machine with a turntable. The X100a-MT model is equipped with an automatic alarm system that activates in an emergency and promptly alerts the operator to any problems. This feature ensures a safe working environment while preventing potential damage to the machine or product.