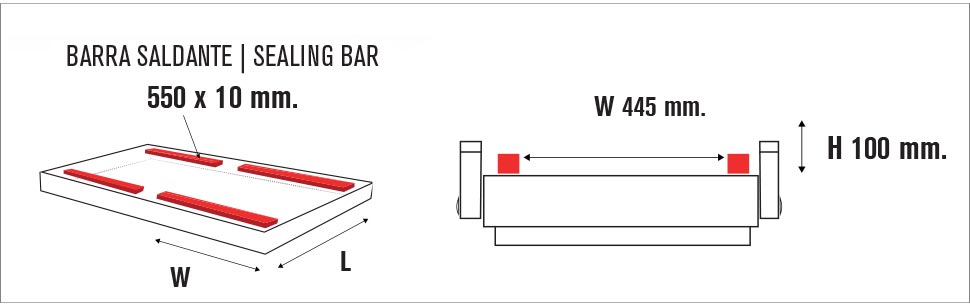

Vacuum welding machine equipped with 4 welding rails to achieve high production capacities

The ULTRA VAC 550SP has been designed for packaging industrial and food products that require high production capacity. They are made from stainless steel to ensure a high standard of hygiene and resistance to acid, mould and rust. The sliding chamber allows for high speed packaging.

Optional features

- Stainless steel cover

- Gas injection kit

FROM THE CONTROL PANEL IT IS POSSIBLE TO SET

10 MODES FOR DIFFERENT WORKING CYCLES

BAKE TIME

- Vacuum time in the chamber.

The vacuum gauge can be used to check the vacuum value.

TECHNICAL GAS INJECTION TIME

- On models with predisposition, the amount of gas injection can be decided by adjusting the “gas injection time”

TISSUE TIME

- Bag sealing time. It depends on the thickness of the bag and the material. It usually takes 1 or 2 seconds.

SEAL COOLING TIME

- The chamber remains closed and puts pressure on the sealing bar. Ensures a durable seal of the bag.

TWO-DIGIT COUNTER

- The counter displays the number of working cycles.