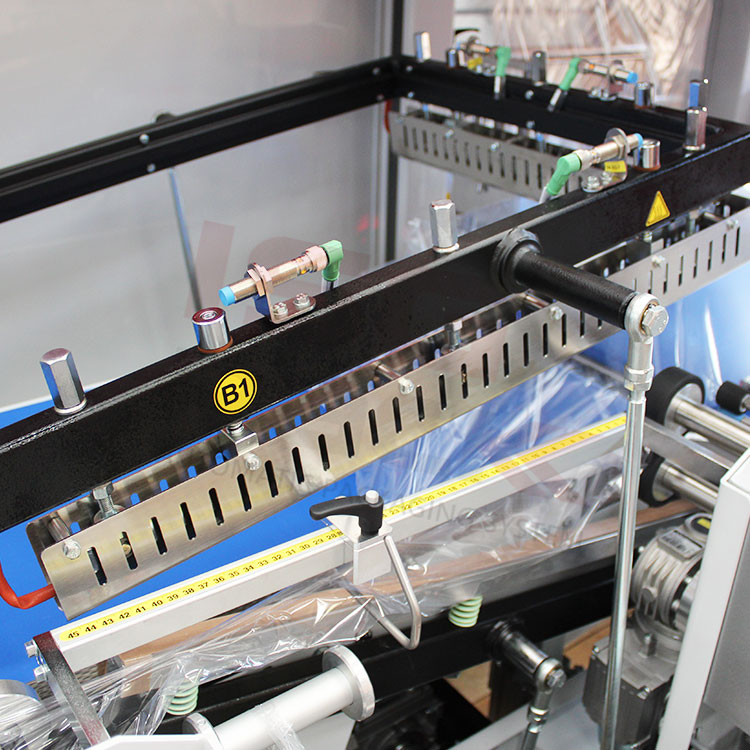

The automatic L-tunnel seals, Matic Sealer 85 SC, are of high quality and very good price and can be purchased with or without shrink tunnel. These machines can work with centre-folded polyethylene and polyolefin shrink film and have a production capacity of up to 3600 packs per hour. These models feature motorized seal centering.

Use

The powerful conveyor moves the products to the center folded film, the photocells detect the products and the work cycle starts. The feeding, unwinding of the film, sealing and output of the products are fully automatic.

Options

- Equipment for centering printed film

- Sealing strip for polyethylene from 15 to 60 my

- Cold foil perforation equipment

- Supply belt enlarged by 500 mm

- Protected outfeed roller conveyor with free running rollers with 46 mm pitch and 1000 mm length.

Features

- Automatic L-seal with shrink tunnel

- Motorized sealing bar controlled by inverter and sensor

- Conveyor locking system included

- Motorised centre sealing system

- Teflon-coated sealing blade

- Emergency button

- Safety equipment

- Continuous sealing cycle

- FLXMOD® control system equipped with: 4.3″ LCD graphic control panel with PLC

- Modular power section consisting of: inverter for all motors IN/OUT (input/output) digital and analogue control modules

- This system allows simple and precise control of all machine operations, for example: the possibility of storing up to 20 different operating programs.

Operations

- Automatic control of the sealing bar height

- Double temperature adjustment of the sealing bar in both longitudinal and wide direction

- Sealing time setting

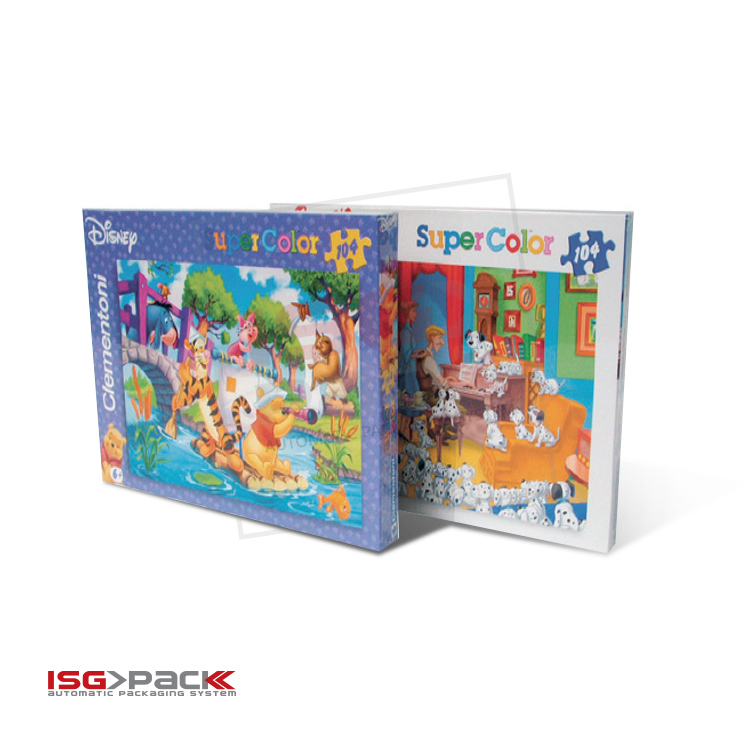

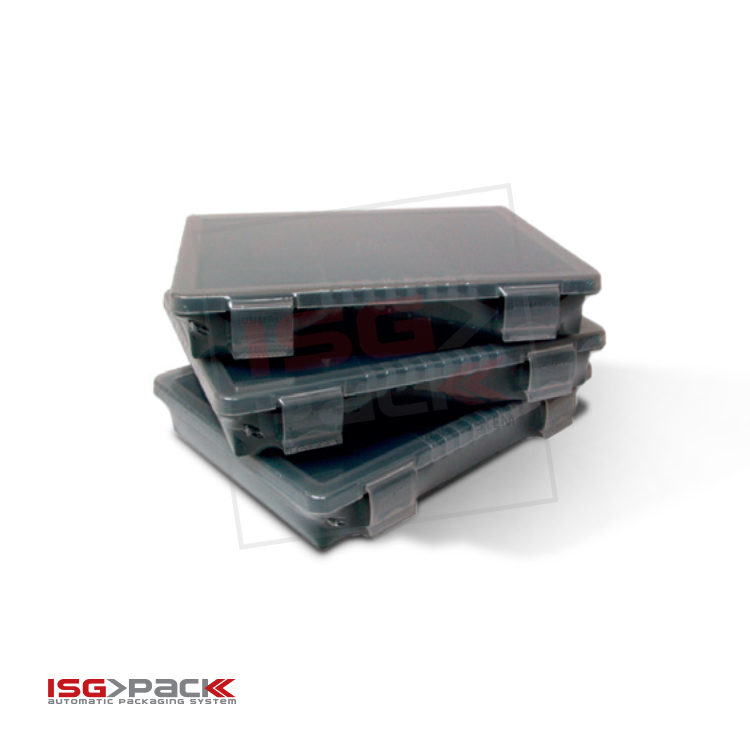

- Possibility to pack single packs or multiple packs

- Conveyor speed electronically adjustable from the process statistics control panel

- Reduced energy consumption

Benefits

- High capacity and speed: the Matic Sealer 85 SC is designed for fast and efficient packaging of large volumes of products, significantly increasing productivity.

- Automation: the fully automatic system reduces the need for manual labour and increases packaging efficiency. Automation also minimizes the risk of human error.

- Flexibility: this model offers a wide range of settings including temperature, speed and shrink time, allowing it to adapt to different types and sizes of products and packaging.

- Precise and reliable sealing: the Matic Sealer 85 SC provides a consistent, high-quality seal that protects products during transport and storage.

- Energy efficiency: the machine is designed with energy efficiency in mind, leading to reduced operating costs and a smaller environmental impact.

- Easy to use: an intuitive control panel with a user-friendly interface makes the machine easy to set up and operate, simplifying the work of operators and reducing the need for intensive training.

- Compact and robust design: the compact dimensions and robust design allow the machine to be easily integrated into different work areas and ensure a long service life.

- Low maintenance: The machine is designed to require minimal maintenance, which reduces service costs and minimizes downtime.

- Waste reduction: efficient use of shrink wrap reduces waste, which is economically beneficial and contributes to environmentally friendly practices.

- Wide range of applications: The Matic Sealer 85 SC is suitable for packaging a variety of products including food, industrial goods, electronics and consumer goods, making it a versatile solution for a variety of industries.

- Safety features: modern safety features protect operators from potential accidents and ensure safe machine operation.

- High build quality: robust and durable design ensures long machine life and reliability, which is important for intensive use in industrial environments.