Fully Automatic High Speed Strapping Machine

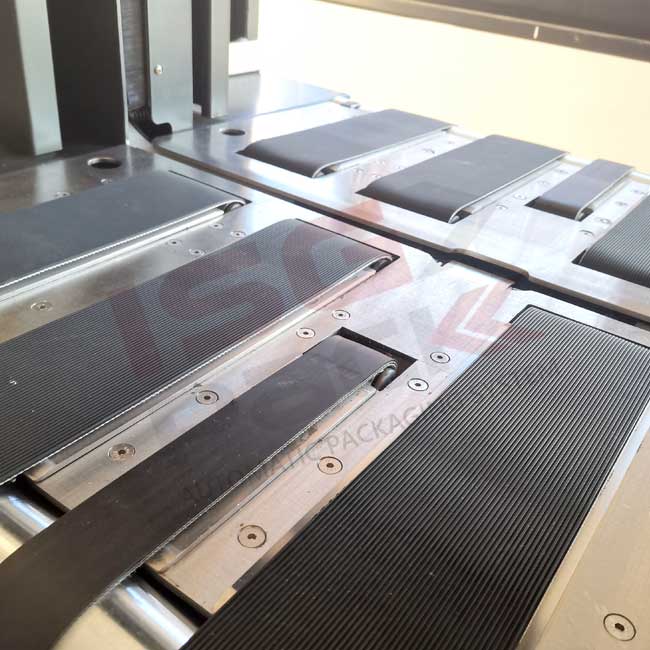

The Speed Strap B series is a high performance strapping machine that can also be inserted into automatic packaging lines, guaranteeing high productivity and a high standard of reliability. It operates with 24 VOLT Vcc brushless motors arranged for each machine function and has a work table integrated with 8 motorized conveyor belts, two of which are smaller and are located in the middle part of the work table. This makes it possible to tape even small sized products. Photocells are installed at the inlet and outlet of the product to automatically perform single, double or multiple tapes. The strapping machine is also available in a version with pneumatic stabilizing press and in a stainless steel SUS 304 version.

General characteristics of the strapping machine

The fully automatic Speed Strap strapping machine uses a 220V | 1 ph | 50/60 Hz power supply and has an adjustable work plate height from H 870 to 970 mm. It has a strapping speed of 50 cycles per minute with a maximum adjustable tensioning force of up to 45 kg. The strapping machine is equipped with an integrated work plate with 8 motorized belts and 2 reduced sizes located in the middle part of the plate, 7.2″ touch screen control panel, 2 photocells for automatic execution of 1-2 or more tapes, 3-color flashing column, transit mode function, no product strapping, easyfast® strap guide disassembly system (no tools required). There is also: automatic ejection of a piece of tape at the end of the spool, adjustment of the welding cooling time (COOL TIME), adjustment of the welding blade temperature, tape cutter, automatic tape loading system, magnetic safety sensors. The strapping machine is available on request with different arc sizes.

Features and parameters of the strapping machine

Technical features of the strapping machine

- Work table with motorised conveyor belt

- Stainless steel safety handle

- Safety barriers with magnetic safety switches on each door

- Automatic tape feeding

- Input and output signals displayed on the touch screen

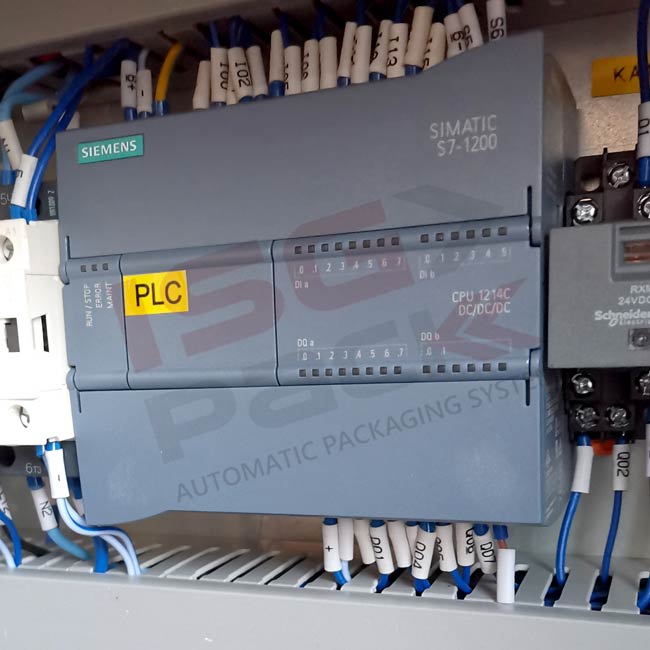

- Strapping group controlled by 24 volt brushless motors

- Single, double or multiple tapes

- Transit mode without product banding

- Belt speed adjustable by inverter

- Acoustic and 3-colour light signal

- Loop extension

- 7.2” touchscreen

- Tape cutting equipment

- Adjustable workbench height

- Four swivel wheels, two with brake

- Easyfast system for removing the tape guide (without any tool)

- Automatic tape ejection at the end of the tape spool

- Re-feed tape system

- Possibility to use different tape sizes

- Different sizes of arches are available

- Tape tensioning up to 45 kg

Parameters adjustable from the control panel

- Tape tension adjustment with potentiometer

- Sealing blade temperature adjustment

- Manage the “transit mode” function without taping the product

- Single, double or multiple tape system setup

- IN/OUT interface for connection verification

Characteristics of the processable product

- Max. Product dimensions: w 600 x h 450 mm (with curve from w 650 x h 500)

- Product weight: 30 kg.

Features of the webbing scrolling

- Inner diameter: 200 mm

- Outside diameter: 400 – 450 mm

- Tape width: 5 – 9 – 12 mm

- Tape thickness: 0.45 – 0.65 mm

- Strap type: PP (polypropylene)